3 Reasons why machine builders should incorporate remote access tools

In this modern age, the world around us is becoming more connected than ever before. Internet connected devices give us many conveniences in our personal lives, but how can we use this technology in the industrial environment? Let’s discuss the benefits of adding remote connectivity to your machines, focusing on three main benefits.

#1. Deliver more value to end users

Whether you are looking to retain customers or gain an edge in a competitive market, adding value to your machine is often beneficial for both the OEM and user. Here are some ways that adding remote connectivity can provide value to your customers:

- Exceptional customer service is proven to help retain customers and drive greater profitability. Remote connectivity delivers greater customer service by providing the ability to quickly respond and provide solutions to problems that arise during machine operation.

- Additional and consistent data can give users greater insight into their processes. This can provide value such as increased process efficiencies, reduced material scrap, or increased product quality.

- Insight into the process can trigger predictive maintenance and repair procedures or alert to early signs of failure. This can give users more predictable and manageable downtime procedures.

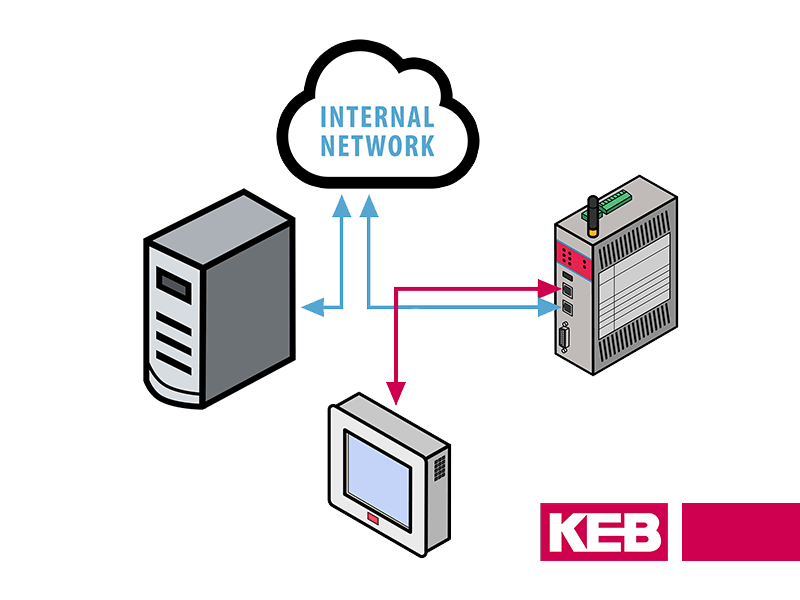

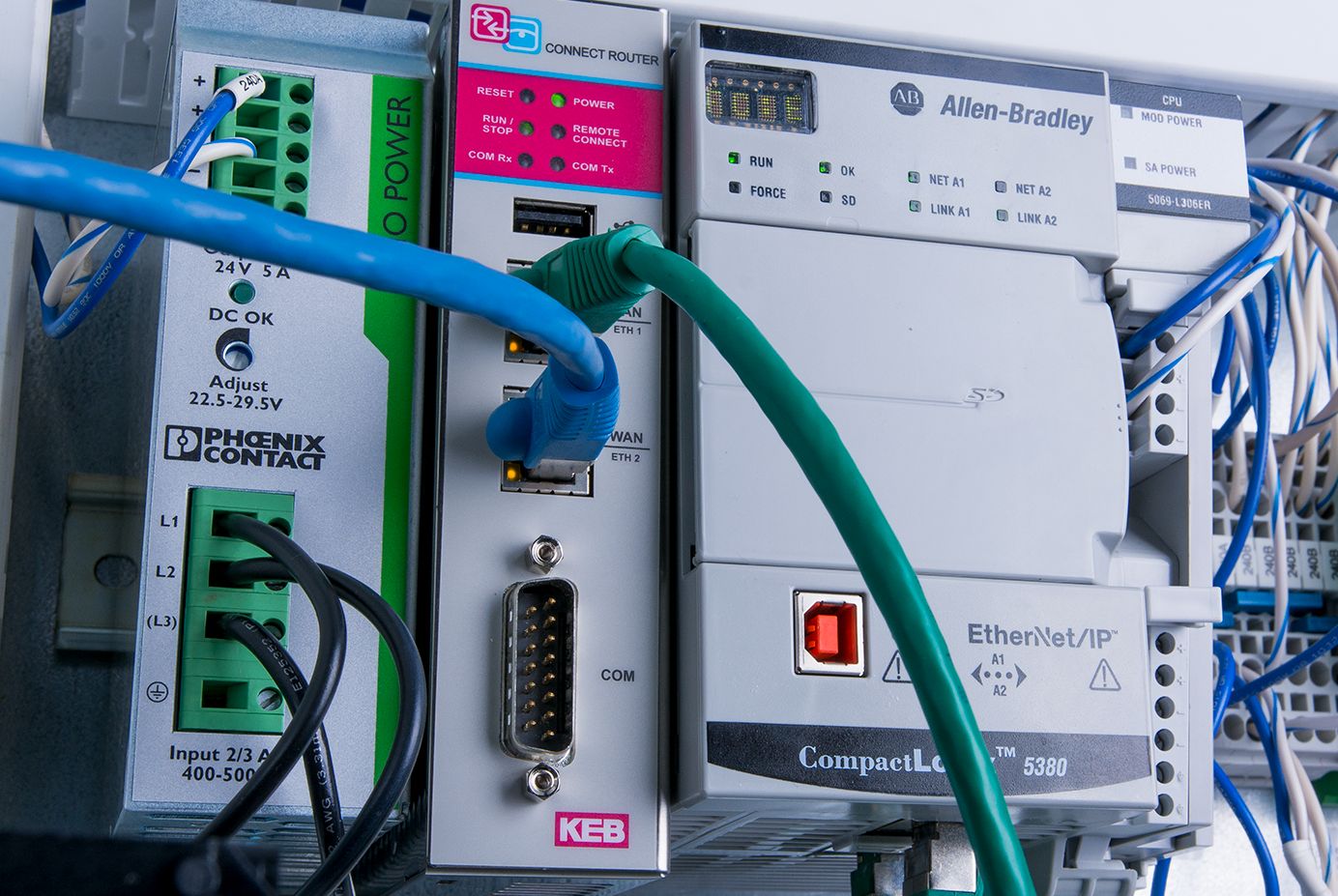

- Utilizing industrial grade connectivity products such as KEB’s C6 Industrial VPN Router provide safe and secure connection to machines. KEB’s Router hardware and COMBIVIS Connect infrastructure have been 3rd party audited to meet cybersecurity standard IEC 62443. Adding this level of connectivity to machines can avoid potentially costly security breaches from incorrect connectivity integration in the field.

- Options such as cellular routers give flexibility to system design and offer solutions for machines in rural or remote locations.

#2. Reduce Service Call Costs

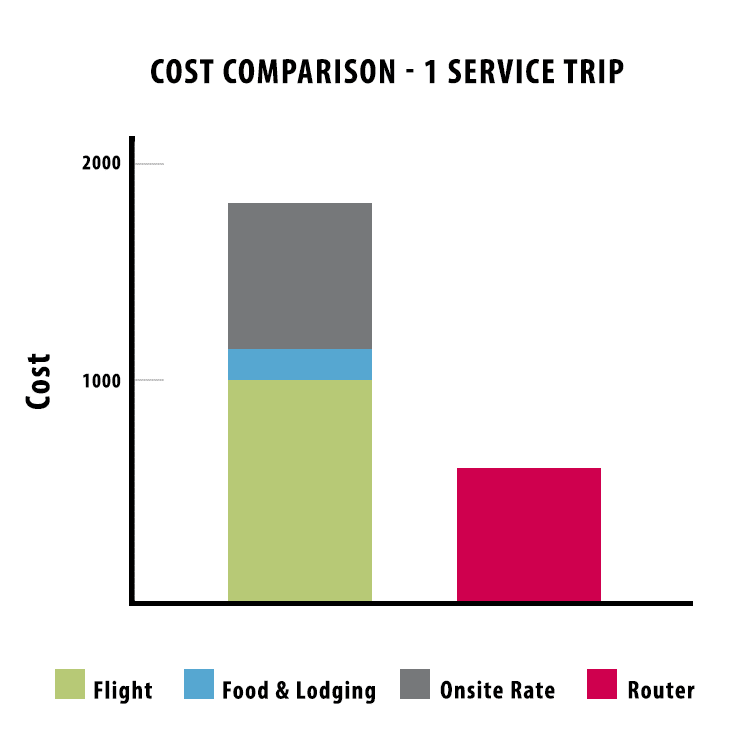

Traveling is expensive and difficult. Adding remote connectivity can significantly reduce the cost of responding to problems that arise during machine operation. When troubleshooting can be done remotely, we have found that adding remote connectivity can pay for itself in just one service call (see Figure 1). Not only do you save on travel, lodging, meal and wage expenses, but also on your technician’s valuable time that could be spent on other activities than traveling. Time is money, and there is an opportunity cost by not using remote access.

#3. Additional revenue stream from aftermarket service

Machine builders incoming revenue can be affected by the economy, industry trends and even legislation. This can make cash flow and budgeting challenging. MRO parts provide a continuous revenue stream that helps in slow times.

Offering remote service plans offers an additional way to create a known and recurring revenue stream while offering value to customers. Here are some strategies for utilizing and selling aftermarket services:

1. Maintenance contracts can provide continuous revenue sources. Utilizing remote connectivity allows you to add to existing maintenance contract options or offer new solutions for your customers.

2. One-time service charges can give you and your customers an easy way to execute routine maintenance or troubleshoot problems that arise. Less cost for you and maybe for the customer too. A win-win scenario.

3. Leverage your industry experience and remote connectivity ability to offer data services. This could be data collection, monitoring or process control. KEB offers MQTT integration in the C6 Router, giving you the power to incorporate cloud-based platforms and create dashboard for your customers. See how KEB’s Router can integrate with AWS.

Conclusion

Providing advanced services for your customers not only provide additional revenue, it also provides a better experience for the user. These additional interactions with your customer can also build more rapport and trust in your brand.

Want to discuss how KEB’s Router can help you – Contact an engineer to discuss.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.