4 Duty Cycles for Motors Engineers Need to Know

When selecting a motor, it is important to consider the required duty cycle (including the potential for a higher duty cycle) to ensure the motor can meet the application’s needs. This blog post and the accompanying lightboard video will briefly introduce duty cycles and a few of the most common types.

What is a Duty Cycle for a Motor?

The International Electrotechnical Commission (IEC) defines eight classifications for a duty cycle, grouped by continuous, short-term, or periodic cycles. Duty cycles encompass the frequency and duration of typical operations. These include starting, running with no or full load, electric braking, and resting.

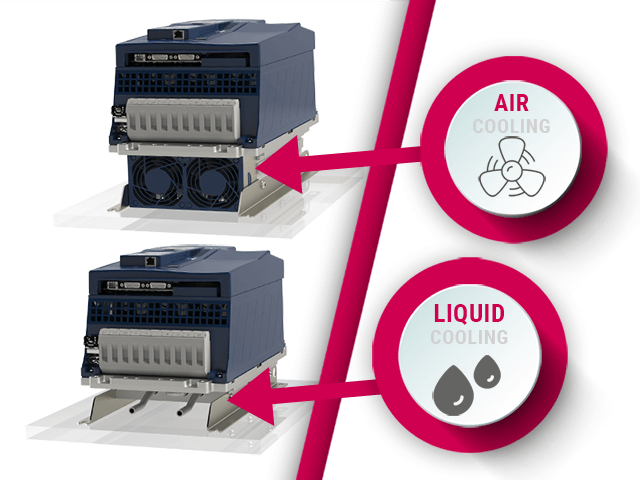

Reviewing these operations helps determine the effect on motor temperature. This informs whether the selected motor suits the application, needs additional cooling like a forced ventilation fan, or requires replacement.

4 Types of Motor Duty Cycles

Once you have identified the type of operational cycle(s) your machine operates, contact us to see how we can find the best solution for your specific application.

1. Continuous Duty Motor Cycle (S1)

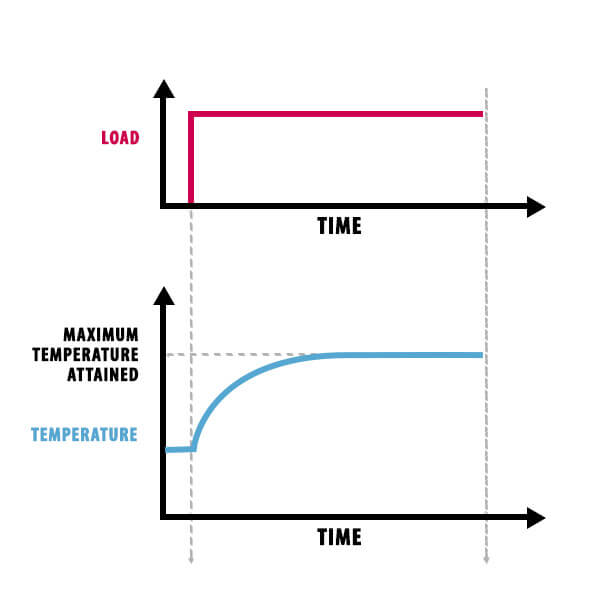

The first, and simplest, type of work cycle is continuous duty. This is also referred to by its abbreviated name, S1 duty (Figure 1).

In this type of operation, the motor runs with a constant load long enough to reach thermal equilibrium. This also assumes the starting of the motor can be considered to have a negligible effect on the motor temperature. An example of S1 duty would be a fan switched on and left running non-stop.

The advantages of non-stop duty cycles include efficiency, dependability, and simplicity. Because motors in constant duty allow the system temperature to stabilize, they offer dependable operation even when near or at their rated maximum capacity.

S1 cycles are ideal for machines expected to run steadily and continuously for long stretches of time. Typical applications of perpetual duty cycles may include escalators, eMobility solutions, a MIG welding machine, or even packaging machinery.

As a leader in control and automation technology, KEB offers a range of flexible motors capable of steady, uninterrupted operation to support your machine-building needs.

2. Short Time (S2)

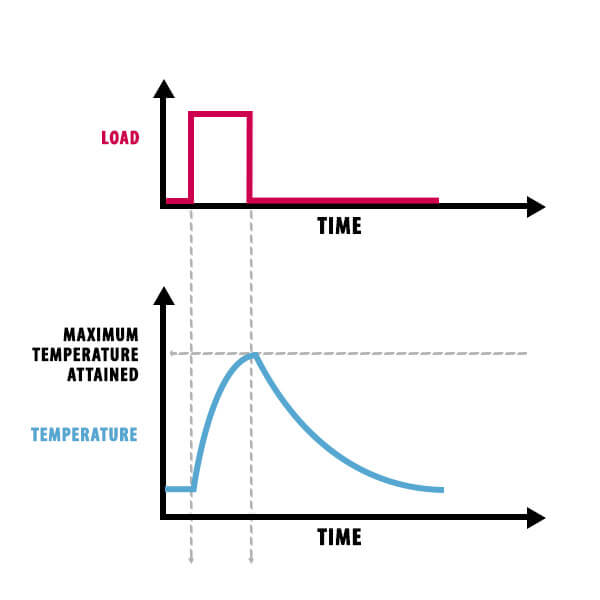

The second type of operating cycle is short-time. Similar to continuous duty, this operation runs with a constant load. Unlike continuous duty, it is shut off before it reaches thermal equilibrium.

Then, the motor rests until it reaches ambient temperature. Short time duty measures S2 followed by the number of minutes in the cycle (S2 30 minutes).

Periodic Duty (S3-S8)

Periodic duty refers to the designations S3-S8. These include cycles with and without rest that have starting, electric braking, and/or changing speeds/loads.

Throughout all of these designations, the various operations of the cycle are repeated over time, and the motor is not allowed to reach thermal equilibrium.

Periodic duty cycles are often ideal for machines with rapidly changing or unpredictable load demands, such as elevators, punch presses, compactors, or even industrial saws and other metalworking machinery. These machines can shift load demands within seconds, requiring a flexible motor duty cycle that can sustain these periodic operations without stalling or overheating.

KEB has a variety of adaptable motors that offer unmatched feedback and brake options to match your unique application needs and specification. A printer duty cycle is another example of periodic duty. Considering a monthly duty cycle is particularly important when selecting a new printer. When buying a new printer, one must consider the duty cycle of a printer, recommended print volume, and the duty cycle limit.

Printers have varying load demands during different printing tasks, and a suitable motor duty cycle is needed to handle intermittent operations without compromising print quality, overheating or reaching a breaking point.

KEB offers versatile motors designed to meet the specific requirements of

printers, ensuring smooth and reliable operation. In addition, factors such as pages per month recommended monthly print volume, and power supply should also be considered when selecting a printer.

3. Intermittent Periodic Duty (S3)

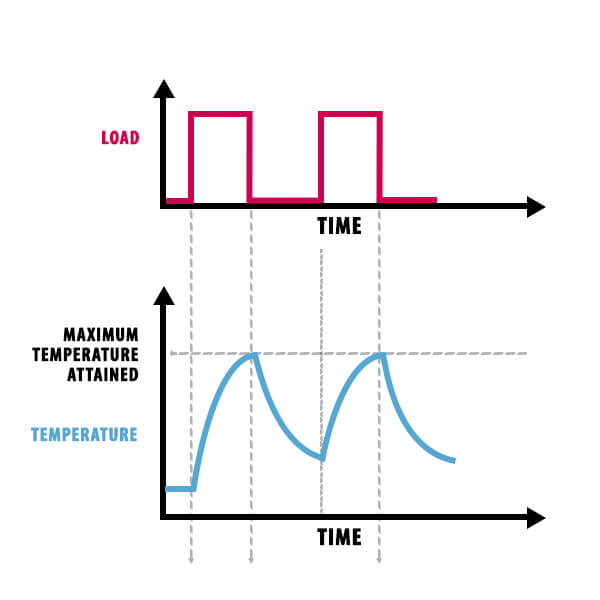

Intermittent periodic duty is the simplest type of variable duty. This sequence of identical cycles each contains a period of constant load and a period at rest. This is very similar to S2 duty but differs because it never reaches ambient temperature during its rest period. This duty cycle is abbreviated as S3 followed by the percentage of time under load (calculate S3 xx%, where the % = ∆Tc/T).

An example of intermittent periodic duty could be a conveyor that runs at constant intervals with the same loading.

Thanks to its unique nature, S3 minimizes heat and allows manufacturers to invest in smaller-sized motors, which translates to significant cost and weight savings. Intermittent periodic duty cycles can be deployed across a host of applications, including plastics machinery, food and beverage processing, and more.

Packaging is also a common use case for S3 cycles, as this application often entails consistent load factor and run intervals.

4. Perpetual Operation with Electric Braking (S7)

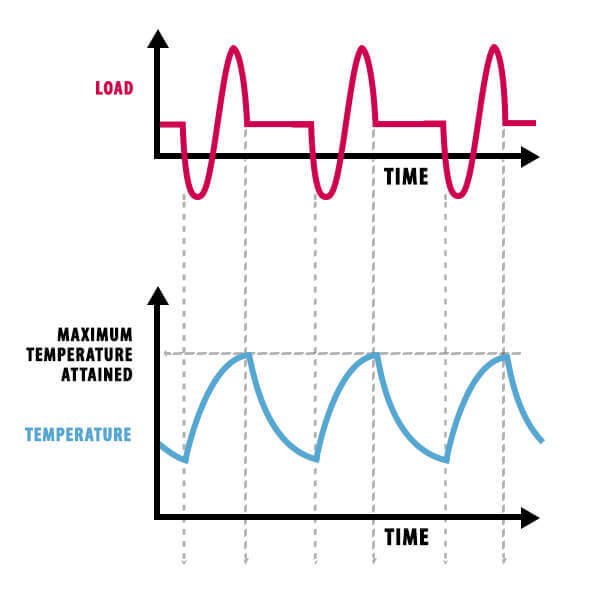

The final example of a duty cycle is non-stop operation with electric braking. This cycle includes a starting sequence, constant load, and electric braking. Additionally, there is no time during the rest operation. This type of duty cycle is abbreviated as S7 followed by the moment of inertia of the motor and load (Jm and JL).

The other periodic duty cycles S4-S6 and S8-S9 are similar to S3 and S7 but can be done with or without rest, starting, braking, and loading. Potential applications of sustained operation with electric braking could include rolling or blooming mills for steel manufacturing, supply chain machinery across material handling, and even some medical technologies, including precision applications.

With decades of experience, KEB Application Engineers help machine builders determine their ideal duty cycle. We provide a range of flexible motors, such as robust brake motors. These motors blend industry-leading technology with potent DC spring-set brakes.

Before You Purchase a Motor

Consider the operation requirements and declare the duty cycle, such as maximum and high duty cycles, when purchasing a motor. This approach ensures the selection of the right motor for the application, whether it’s TIG welding or other commonly used welder machinery.

For more information on how duty cycles are calculated and to select the best motor for your specific application, contact an applications engineer at KEB America today.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.