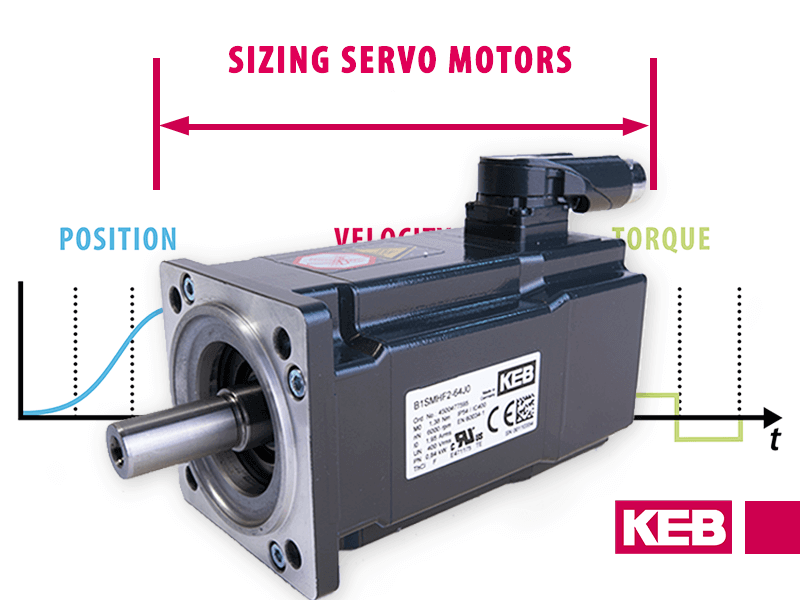

As flexible solutions for machine builders, servo motors pair incredible energy efficiency with compact size, producing up to 60% higher torque capacity versus equivalent-sized induction motors. However, like any tool, servo motors are not foolproof: failures can occur with these motors, impacting productivity and safety. This is why it’s essential to understand the typical causes of servo motor failure.

Keeping tabs on these largely preventable problems will help limit downtime and ensure you get the best performance from these motors across their lifespan.

How Do I Know If My Servo Motor is Bad?

Early identification of a failing servo motor can be the difference between a simple repair and a costly replacement. Warning signs include:

- Unusual noises

- Reduced efficiency

- Error messages from the control system

Regular preventative maintenance checks can help identify these issues before they escalate.

Why Do Servo Motors Fail?

Failures boil down to a few common factors like inadequate maintenance, mechanical wear and tear, and harsh environmental conditions. However, we narrowed the most common failures to five causes:

- Bearing failure

- Brake failure

- Winding and cable failures

- Contamination

- Overheating

Timely servo motor repairs and adhering to a proper maintenance regimen are your best defenses against these failures.

1. Bearing Failure

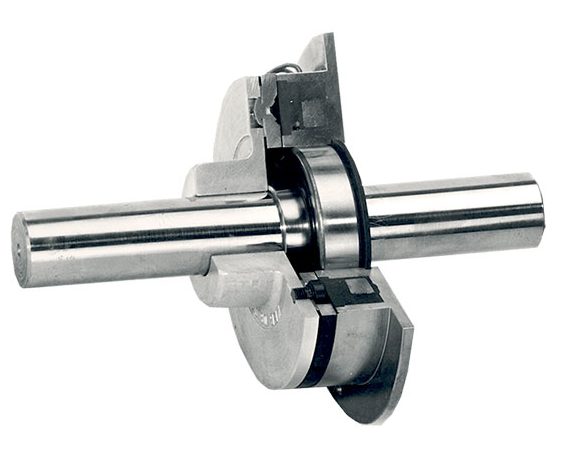

Bearing failure in servo motors is highly common and has multiple causes. Of course, bearings naturally wear out over time with repeated use. Incorrect installation or reinstallation of the motor can also misalign these bearings.

A telltale sign of bearing failure is abnormal sound, including growling or screaming, while the motor runs at high speeds.

Predictive maintenance is the best method to prevent bearing failure. Consistently checking the motor to swap out bad bearings will significantly improve the motor’s lifespan – and allow you to schedule repairs at convenient times that won’t impact productivity.

Working with a trusted repair partner is crucial to replace bearings correctly. Critical applications might also consider using motor-mounted vibration sensors, which can help detect a bearing failure early.

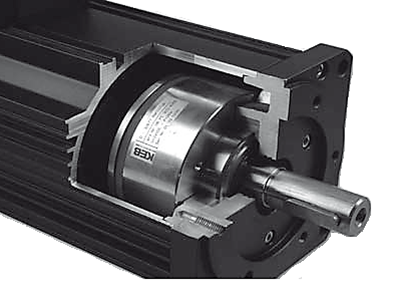

2. Brake Failure

Servo motor brakes hold a load in place when the drive is deactivated or shut down. Most servo motor brakes only hold and are not designed for dynamic stopping. Using the brake for repetitive stopping or multiple e-stops could cause it to wear and require replacement.

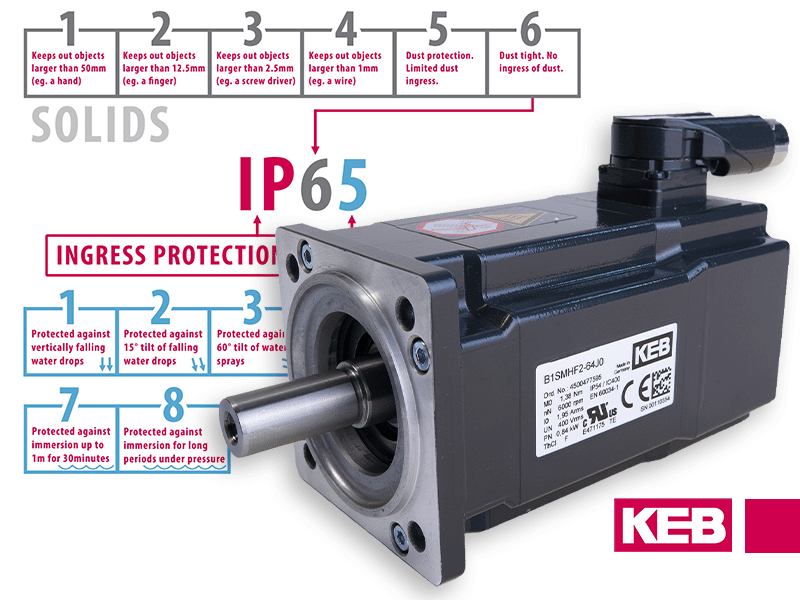

Since many servo motors are designed with IP65 protection, the brake is often enclosed in the housing and is not easily checked or replaced. A best practice is to engage the motor brake at a standstill. After the brake has engaged, the current that drives the motor can be deactivated.

For machines requiring brakes for occasional emergency stops (e-stops) and dynamic stopping, it’s advisable to use a separate, specialized brake. Options like KEB’s Double C-Face or Spring-Set Brakes are designed for repetitive dynamic stopping and are ideal for these situations.

3. Winding & Cable Failures

Bad winding often leads to servo motor failure. Water contamination can damage the motor’s copper coils or gradually deteriorate due to the natural vibration during motor operation.

Similarly, the system’s power, control, or feedback cables can lose integrity over time, causing failure or voltage spikes that shut down the motor.

It’s critical to check for winding failure if the servo motor becomes exposed to any contaminant, including coolant or water. (We’ll touch on this point more below.) You should also check uncontaminated windings since they naturally wear. Rewinding the defunct coils will keep the motor operating well and maximize its lifespan.

Investing in reliable cables is one of the best ways to prevent cabling malfunctions. A high-quality feedback cable will boost the entire performance of the system, enabling fast, error-free connections.

Regardless of quality, test your cables as part of troubleshooting efforts.

4. Contamination

Contamination is a root cause behind many motor issues we’ve touched on. Even though servos are generally durable, they can be significantly affected by certain substances, such as coolant, oil, and common debris like dirt.

The latter can block up system-critical parts, including fans, which causes overheating. Liquid contaminants can impact the motor’s bearings, encoder, windings, and more.

Diligence is critical in avoiding servo contamination, as are regular inspections and cleanings. Fully closed motor systems and sealing the motor windings can help prevent these harmful substances from entering and affecting the system, especially for those running in harsh environmental conditions.

5. Overheating

Overheating is a critical threat for most machines, including servo motors. Excessive heat may damage motor and connected systems parts, incurring costly downtime.

Frequent causes of heat damage in servos include blockage in the motor, high environmental temperatures, and extended operating times.

Heat damage is often insidious. An overheated servo may not show obvious signs of damage but will eventually fail. Thankfully, most servo motors include a failsafe to shut down the system when the temperature exceeds a safe threshold.

Worn-out parts often cause overheating in older motors, so replacing those old parts can quickly resolve and mitigate any issues. Ideally, servo motors will operate in climate-controlled environments to limit excessive heat, but this is only sometimes possible.

Proper ventilation will help manage the threat of overheating servos—as it will allow the stressed system enough time to cool off before continuing operation.

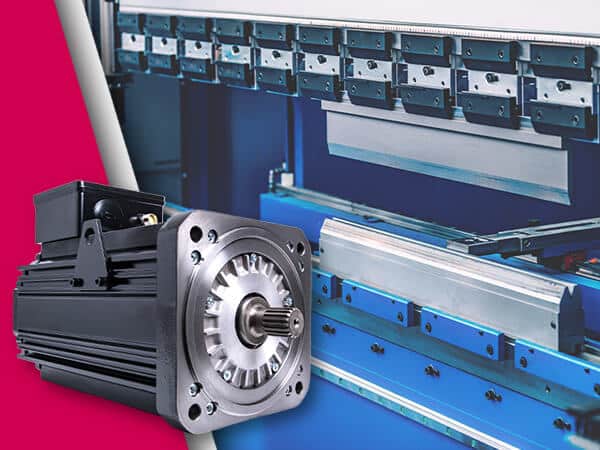

KEB Servo Motor Solutions

KEB’s line of versatile servo motors and servo drives allows you to take full advantage of this powerful technology. Contact a KEB Application Engineer today to learn about our cutting-edge servo solutions and how they can unlock new efficiencies in your application.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.