Since KEB is a German-based company, we have a long history connecting our PROFIBUS and PROFINET drive products with Siemens PLCs. KEB’s PROFINET offering now extends to the next generation S6 Servo Drive and F6 VFD product lines.

Our customers choose KEB PROFINET servo drives for a number of reasons. Customer feedback shows they value KEB’s direct support from engineers, good value (price vs. performance), and a lot of technical features built into the KEB product as standard.

This post focuses on the 6th generation (x6) drive features that make KEB a great choice for your PROFINET project.

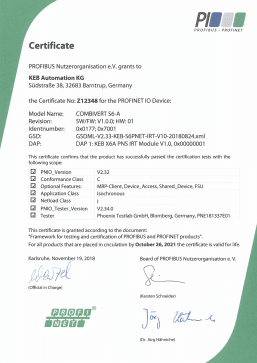

1. Certified by the PI Organization

KEB has offered PROFIBUS and PROFINET drive products since the ’90s but the products were not always certified by the Profibus Trade Organization. In the past, a PROFIBUS device could be released without any sort of qualification or testing. Sometimes, this resulted in the user discovering compatibility issues or that the product did not perform as expected.

KEB’s S6 drive has been tested at an independent lab by the PROFIBUS PROFINET (PI) organization. After successful testing, KEB has received a certificate that the S6A product is a Certified PROFINET device. You can learn more about the certification process on the PI website.

This certification is important to customers since it proves the PROFINET development has been done properly and the KEB device will play nice with products manufactured by other companies.

2. Internal Positioning Module & SCL Posi

KEB drives really shine in difficult and demanding applications. This is very evident in motion control applications that require precise and repeatable positioning. Single-axis applications benefit from KEB’s internal 32-bit position module to handle positioning. This often allows machine builders to use a more economical PLC platform. Or they can forgo purchasing an expensive Motion Controller add-on or software package. More performance for less cost.

Another unique piece of technology is KEB’s SCL Posi which expands on the above-mentioned internal position controller. KEB’s SCL motor algorithms allow for positioning without any traditional feedback device like a resolver, encoder, etc. In other words, this is Open Loop Positioning for an AC PM servo motor.

This technology is really unique and KEB is discovering applications where engineers want to remove the feedback device and cabling because of: vibration, cost, extreme temperatures, extreme cable flex, long cable lengths, etc.

Watch this video for more information on how SCL Posi works:

3. Dynamic Moves with 250% Current Overloads

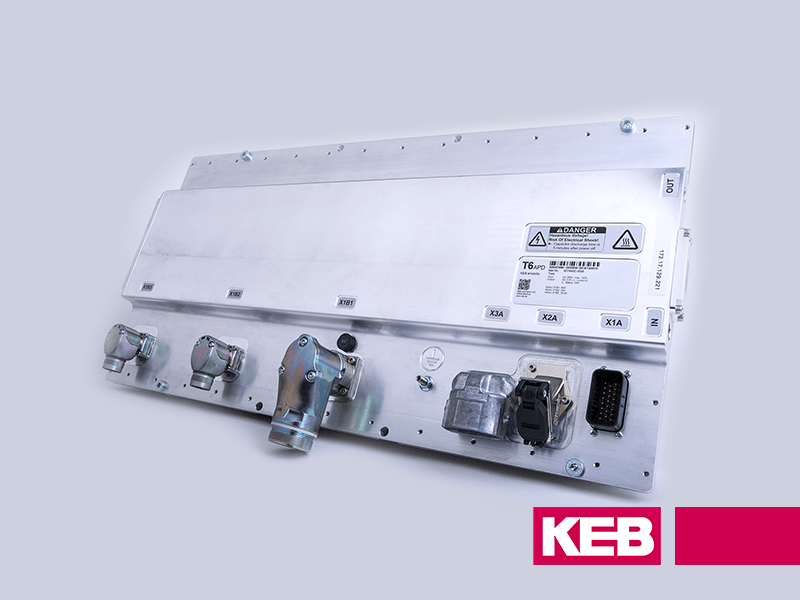

KEB’s S6 servo drive was designed with demanding motion control applications in mind. This means the units are designed with 250% current overloads for aggressive acceleration and deceleration profiles.

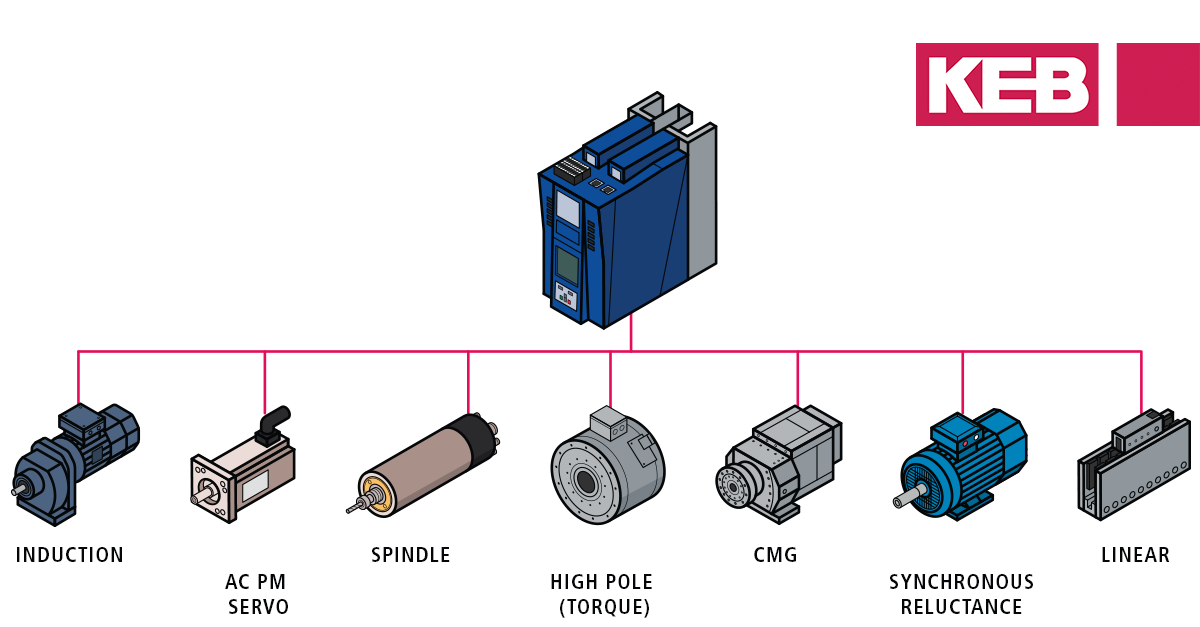

KEB’s F6 drive starts where the S6 ends in the power range. The F6 is more of a traditional VFD and offers 150% current overloads. Regardless, both the S6 and F6 run a variety of different motor types including AC PM Servos, High Pole High Torque motors, Linear Motors, AC induction motors, etc.

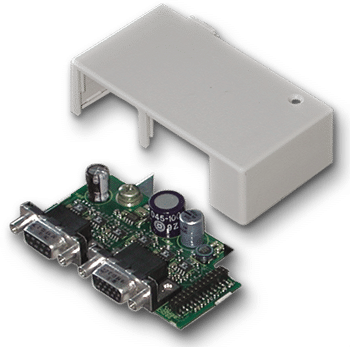

4. Dual-Channel, High-density Feedback

An often overlooked feature in the KEB x6 drives is the use of a dual-channel multi-format encoder input. Previous drive technology required a different encoder board or module for different encoder types. This led to the management of many different SKUs and possibly swapping boards in the field.

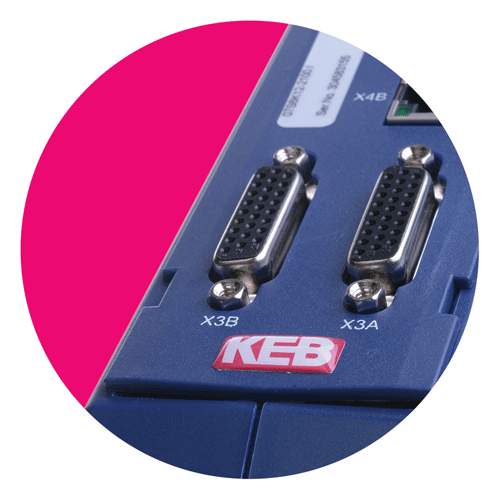

KEB’s x6 generation products feature a high-density 26-pin connector that supports all the major protocols including Incremental (TTL and HTL), resolver, SSI, Sin/Cos, EnDat, Hiperface, and BiSS.

The 2nd channel can be configured as a secondary input or as an emulated encoder output (TTL) for Leader-Follower applications.

5. Scalable Power Range – 230-480Vac, Up to 500Hp

The S6 and F6 share a common control board architecture which means the products provide a seamless power range from 1Hp up to 500Hp. This allows a machine designer to standardize on one drive platform for all automation axes – this could range from a small induction motor running an inbound conveyor to a very large servo motor operating the rotor of a shredder machine.

The S6 Servo drive is unique in that it also has a very wide input voltage range. For 3-phase applications, it allows input of 184VAC-550VAC. All applications get sized off the rated current of the units. Again, this gives a machine builder flexibility in case they offer machines for different voltages worldwide.

6. Support other Protocols from the Same Hardware

If you made it this far in the article you are probably interested in PROFINET. But KEB’s x6 drive products also support many other industrial protocols from one piece of hardware. Our customers can switch between different protocols with a simple parameter change.

Our customers are telling us that they value this because they sometimes sell a machine globally and offer different control platforms – EtherNet/IP and PROFINET for example. This flexibility in the drive allows them to standardize on one platform of drive hardware which benefits part stocking, spare parts availability, and support.

Better Machines start with Better Drives

Are you unsatisfied with your current PROFINET drive offering or at least interested in exploring what other technology is out there?

Contact a KEB engineer to inquire about a demo or a test unit.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.