7 Steps to Reducing EMI with VFDs

This is the second of a two-part series reviewing EMI in VFD applications. The purpose of the first article was to get you better acquainted with the basics of EMI as it relates to industrial controls and VFD applications.

This article will review 7 tips to mitigate EMI-related problems. When considering EMI, there is always a source, a victim, and a path. Each tip below will use grounding, shielding, or filtering methods to mitigate EMI-related issues.

Ensure the VFD and other components are earth grounded appropriately

The earth ground is very important and provides a return path to drain high-frequency noise. In general, a low impedance path should be created which will allow the EMI noise to drain.

Considering this, the ground connection should be kept as short as possible. A flat braided ground strap is a good choice and provides an increased surface area for connections. Finally, the ground conductor gauge should be sized appropriately for the current – a conductor that is too small will offer high resistance and not drain as effectively.

Grounding the VFD achieves two important goals: limiting the possibility of electric shock by providing a conductor to earth ground, and mitigating EMI issues that could affect equipment across the connected power network.

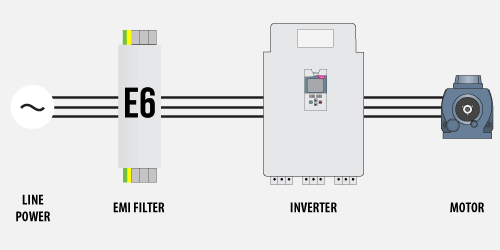

Use a high-quality EMI Filter like the E6

High switching frequencies of the IGBTs at the VFD output interact with stray capacitances of the electric system producing parasitic currents. Parasitic currents generate excessive heat in the inverter and can be transmitted to the supply power through the VFD, potentially disturbing sensitive equipment connected to the supply.

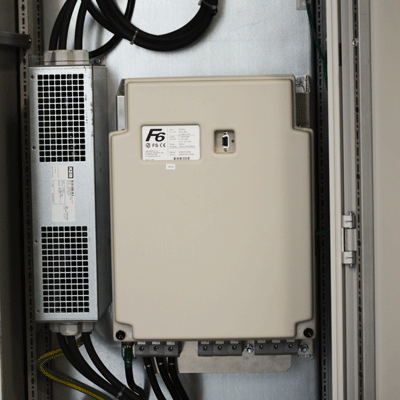

For the best performance use a high-quality filter product like KEB’s E6 EMI Filter. An EMI filter does two things. First, it protects the VFD from high-frequency noise that is being generated by other electrical loads on the power supply. This additional layer of defense minimizes the impact of high-frequency electrical noise—and can help machine builders meet the CE machine directive for filtering. The second core benefit of an EMI filter is that it drains parasitic currents to the ground instead of conducting them back onto the supply cable.

The E6 EMI Filter features a large rated voltage range (0 – 550 V) and offers a compact design in book form with a small footprint. This solution also offers exceptional saturation resistance—as well as innovative filter components to maximize damping area width. When used across the same applications, E6 filters will reduce leakage current to as low as 1/10 compared to standard filters.

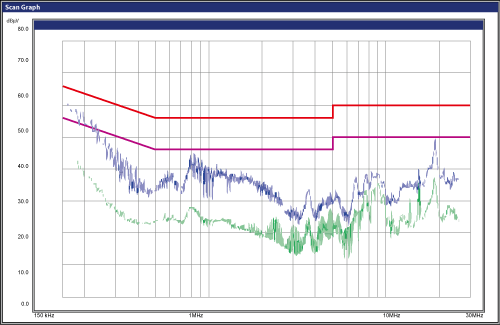

It should be noted that not all EMI filters perform equally. An engineer should verify the performance data across the entire frequency spectrum.

The use of EMI filters is actually mandated in the EU and is part of the CE mark that machinery gets. Different EMI mitigation levels are defined depending on whether the equipment is used in commercial or residential applications. Make sure the filters are tested to meet performance requirements like those called out in EN 61000-6.

The E6 filters are well suited for packaging, food processing, and other machinery applications because they have a low-leakage design. See here for more information on low leakage EMI filters for VFDs—and how you can use these compact solutions to help minimize the impact of high-frequency electrical noise.

Verify the panel is also grounded well to building power

More than once, I have had a tech support call from a user who is bench testing a motor. The drive is behaving erratically and it appears that EMI noise could be the culprit. After investigating, the VFD was found to be sitting on a wooden pallet or bench. Without any sort of earth grounding to the building.

Poor grounding is particularly problematic when a regenerative drive is used to return excess energy from an overhauling load back to the supply. Regenerative drives measure the mainline voltage and frequency in order to deliver excess energy in synchronous with the mainline supply. Voltage notching on the mainline prevents proper regenerative operation and may cause excessive drive and regen faults.

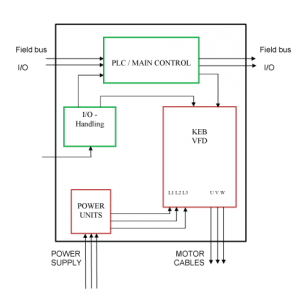

Connect all ground connections to a metal common ground block

A common ground block should always be mounted to the cabinet sub-panel. All ground connections should be wired to this common block. A common ground block provides a single grounding point to reduce potential differences between multiple ground connections. This will also prevent ground loops that allow EMI to circulate.

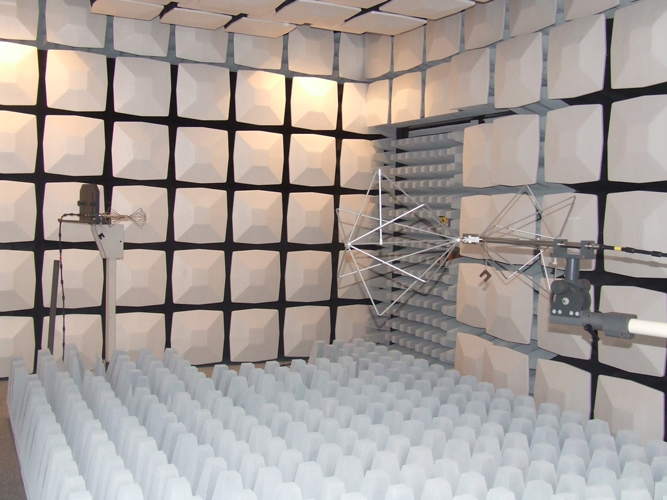

Use shielded cables for control signals

Along with using flat braid ground straps as described above, machine builders can also leverage shielded cable on the load and line side of the VFD to reduce the threat of EMI causing undue degradation in performance. Shielding sensitive control signals can be used to mitigate radiated EMI. For example, it is always necessary to provide an encoder cable with shielded signals. Shielding sensitive control signals can be used to mitigate radiated EMI. For example, it is always necessary to provide an encoder cable with shielded signals.

Permanent magnet motors utilizing high-resolution absolute encoders often use analog signals with a 1V peak-to-peak signal to provide position and speed feedback to the drive. Noise on these signals often results in vibration in the motor and poor ride quality.

KEB offers high-quality encoder cables with double shields and twisted pair wires for noise immunity. These cables are fully compatible with all KEB drive products and offer fast, error-free, and noise-immune connections for almost any application. Shielded cables must always be grounded correctly.

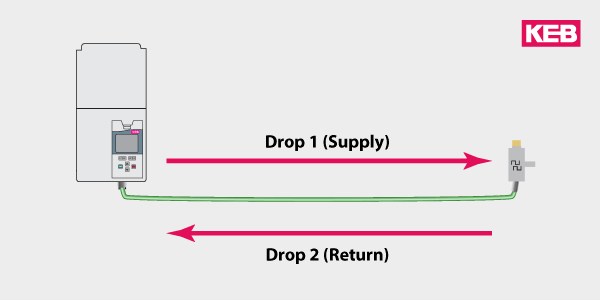

Spatially separate AC supply power, motor cable, high power DC voltage cables, and control and data lines

To prevent high-frequency coupling these wires must be spatially separated from each other a minimum of 8 inches when laid parallel to each other. This precaution will help prevent signals from capacitive coupling with one another and generating excessive noise.

Extra caution should be taken with the VFD output which is especially rich in EMI due to the high-frequency PWM switching.

Install ferrite rings at the inverter output

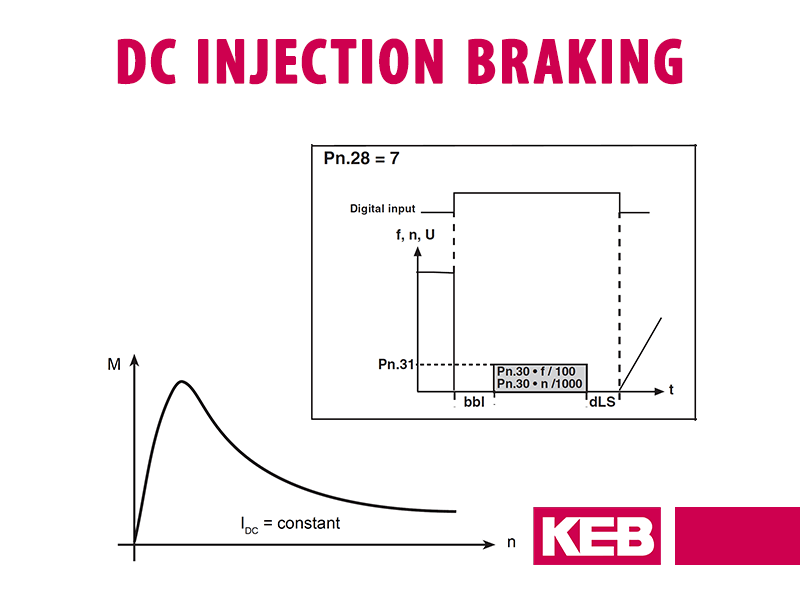

A relatively inexpensive option to reduce common-mode noise is to install correctly sized ferrite rings at the output of the VFD. Common mode noise is a result of the interaction of pulse width modulation and parasitic capacitances of the cable and motor. Common mode noise produced by PWM travels throughout the motor to ground.

The result is high voltages and currents which may contribute to nuisance controller faults, premature failure of motor bearings, and motor windings. The inductance of the ferrite increases the impedance between the VFD output and cable, thus filtering high-frequency currents.

Optimize Your VFD Applications with KEB

Have any other questions about how to reduce EMI-related problems with VFDs? Contact KEB America today and ask to speak to an application engineer.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.