87Hz motor control for Delta Wye VFD operated motors

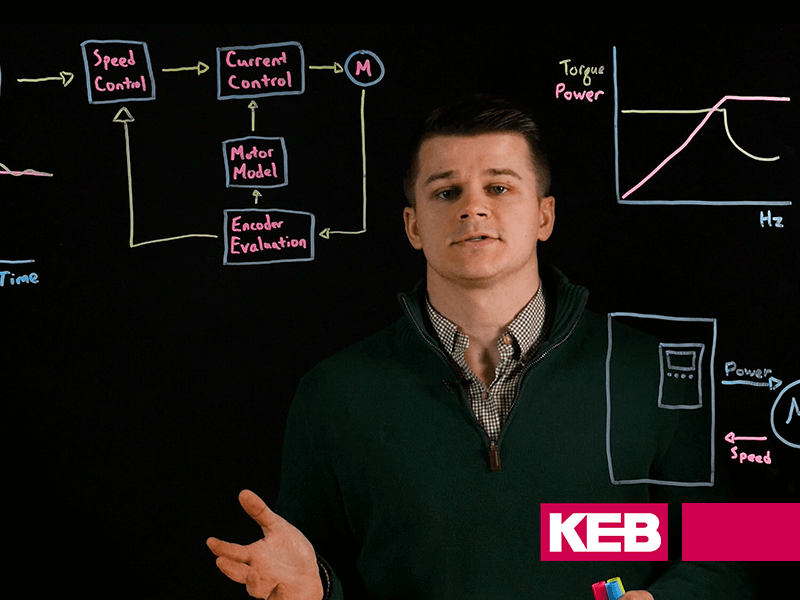

Across KEB’s line of AC induction motors and variable frequency drives, a small trick allows for the output of 1.74 times more power from the same IEC-motor size. This blog post describes how the “87Hz control” works and the benefits it has to offer. In the video below, Mike Keefe explains how this trick works.

After the video, you can read in more detail how the 87 Hz characteristic provides a simple solution to give you more power and torque out of your IEC-motor size.

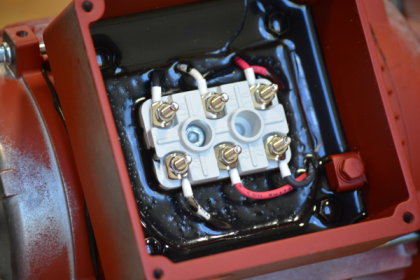

Delta/Wye Motor Operation

Delta/Wye motors (Δ/Y) are wound to allow for two different voltage connections. Depending on the installation voltage, the motor can be wired for either 230V or 400V. This type of winding is typically supplied by European motor manufacturers so the stators are often rated for 50Hz but 60Hz variants do exist.

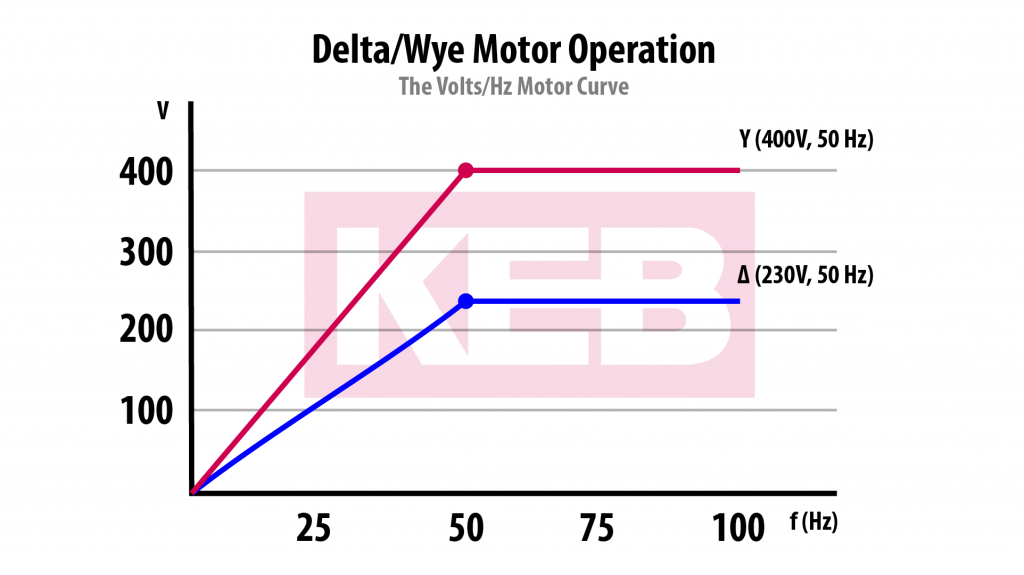

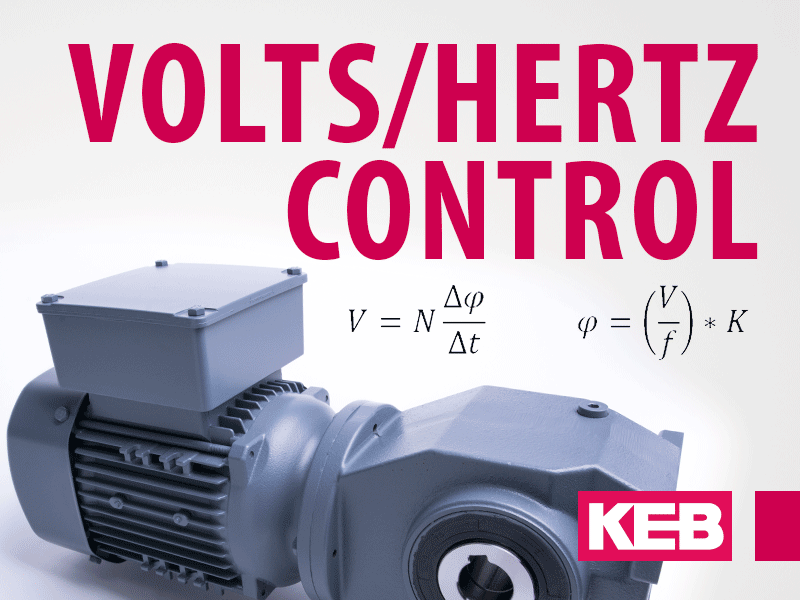

The basic Volts/Hz Motor Curve

During standard open loop operation, the VFD defines a ratio between the rated voltage and rated frequency. For example, when wired for the delta connection this ratio is: 230V/50Hz = 4.6 V/Hz. Thus, whenever the command frequency to the drive is increased by 1 Hz, it increases the output voltage to the motor by 4.6 V. With a 6-pulse VFD, the output voltage is limited by the supply voltage. So once a motor reaches its rated frequency and voltage the output voltage plateaus because there is no more voltage available due to what is supplied to the drive.

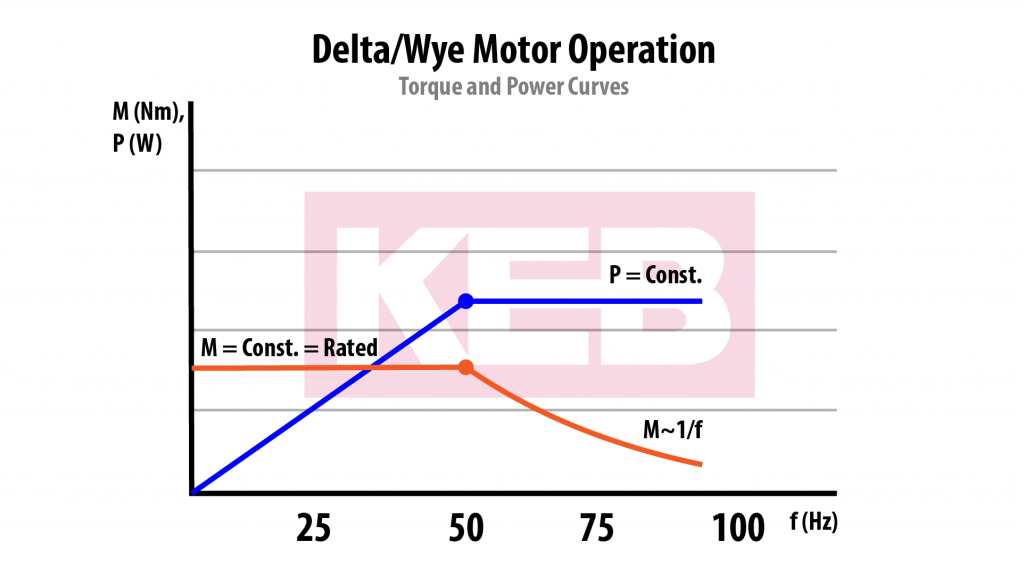

The Torque and Power Curves

Induction motors controlled by a constant V/Hz ratio will operate in a constant torque mode. During operation, the torque will remain constant as the motor is accelerated up to its rated frequency. This constant torque will be equal to the motor’s nominal rated torque.

Power = Torque * Speed. So unlike torque, the power is not constant during acceleration but increases proportionally with the applied output frequency (motor speed).

Beyond its rated frequency, the motor enters what is known as the field weakening range. This occurs when increasing the frequency while keeping the supply voltage constant. The supply voltage is constant because there isn’t any more available voltage from the drive. When operating in this range, the behavior of the power and torque changes. In this range, as the frequency increases, the power remains relatively constant while the torque decreases inversely proportionally to the frequency. This results in the torque dropping rapidly relative to a small increase in the frequency.

In some applications it would be nice to be able to operate in this higher-speed field weakening range without experiencing the drop in torque.

The 87 Hz Characteristic

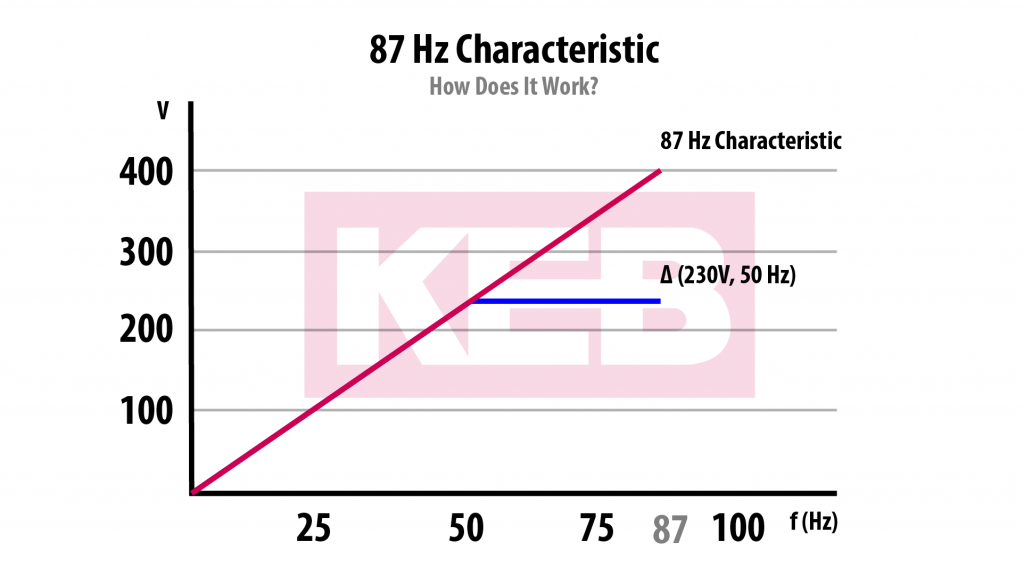

For systems that need to maintain constant torque even in the field weakening range, the 87 Hz characteristic can be used. This allows the Δ (230V/50Hz) connected motor to be operated using a 400V inverter without saturating the motor. This trick also works on 9-wire motors more commonly supplied in North America. The theory is the same and you connect the motor to the lower rated voltage.

How does it work?

During standard operation, providing 400V to the delta connected motor would be too high. Because of this, the corner frequency must be shifted to maintain the same V/Hz ratio. If the constant V/Hz line from the 230V/50 Hz delta connected motor is extended, it eventually reaches 400V/87 Hz (400V/87Hz = 4.6 V/Hz = 230V/50Hz). This allows for constant torque up to 87 Hz instead of just 50 Hz and for a power output increase by a factor of 1.74.

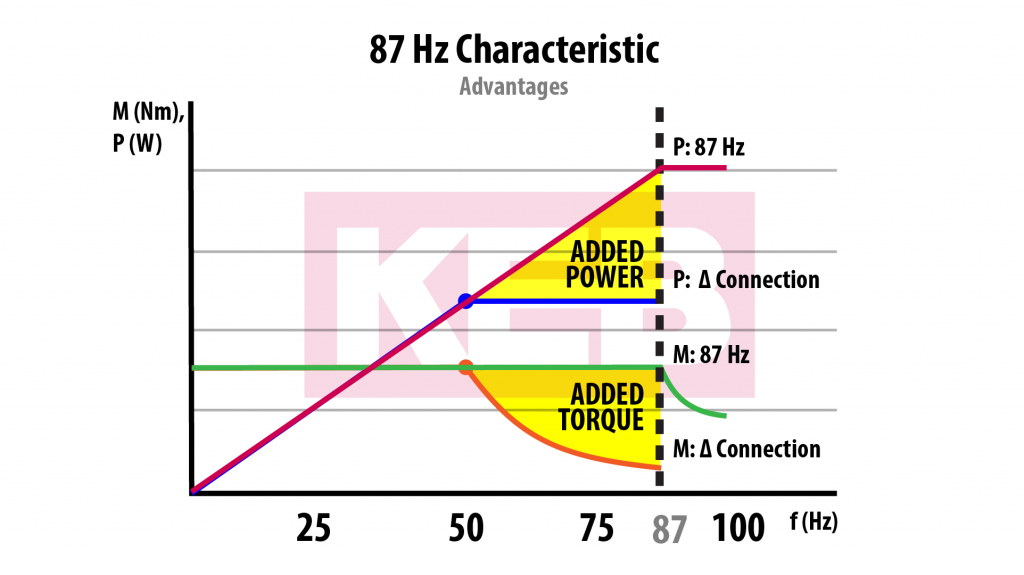

What are the advantages?

Using the 87 Hz characteristic offers multiple, related, benefits. During this operation, the motor is able to maintain constant torque up to 87 Hz with a 400 V supply. The motor can also supply 1.74 times more power compared to the standard 230V/50Hz operation with the delta connection. Because of this, it is possible to get away with using a smaller IEC-motor size while maintaining the same required power and torque. It may also be possible to avoid using an external fan (forced ventilation).

What are the disadvantages?

Power is power and the inverter must be sized appropriately. This means you would use a larger inverter than normally matched with the motor. The inverter will need to be a 400V class inverter but would be sized on the 230V current ratings.

What if my motor and supply are rated for 60Hz?

The 87Hz motor control has been commonly used in Europe with 50Hz mains. For this reason, the name “87Hz” stuck. However, the same method also works on a 60Hz rated Delta-Wye motor with 60Hz mains. However, the operating point with the higher frequency becomes 104Hz (60Hz*1.74) instead of 87Hz..

The 87 Hz characteristic is a simple and easy solution to provide more power and torque with the same IEC-motor size. Interested in learning more about the 87 Hz characteristic or the benefits it could offer your application?

87Hz Trick – See What Else KEB has up its Sleeves

If this article helped you understand the 87Hz Characteristic trick? KEB offers a full line of high performance drives and automation solutions for your application. Ask how we may assist you today.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.