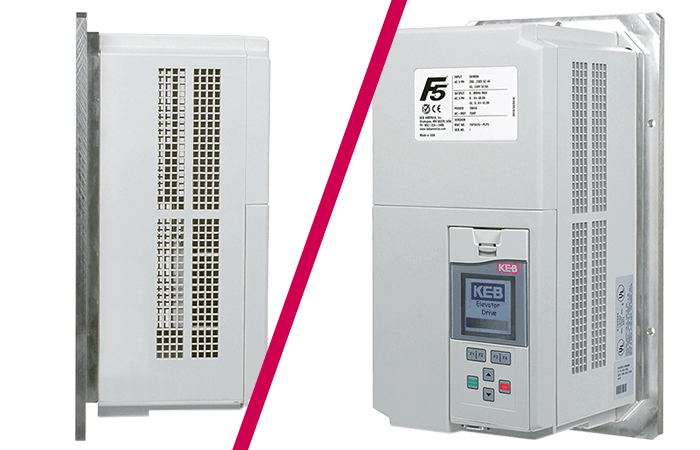

Advantages of the KEB F5 Drive for Spindle Motor Control

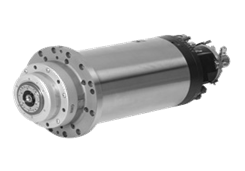

One application that KEB Drives are well suited for is spindle motor control, such as on a CNC machine. This post describes the benefits and services KEB has to offer after our years of experience in this area.

KEB Spindle VFDs – The Benefits

Variety of Motor Control Options

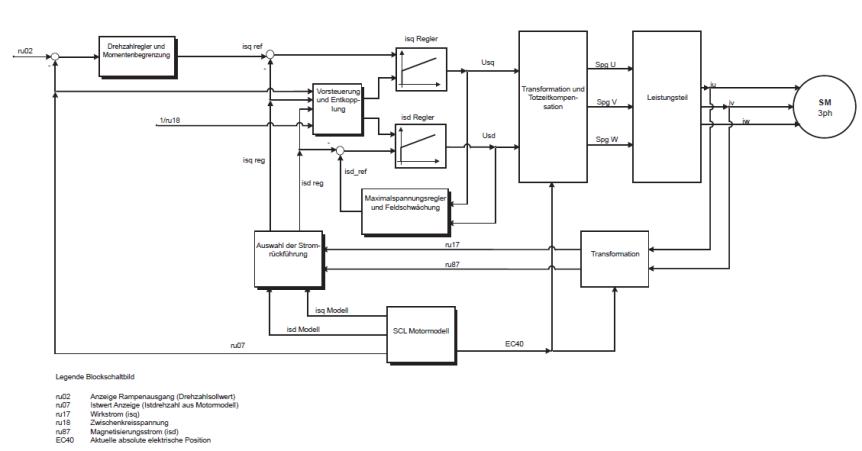

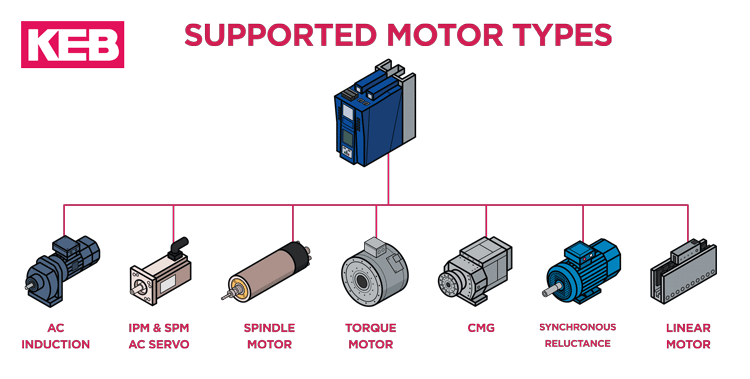

KEB offers a variety of motor control algorithms that allow the F5 to control the spindle in multiple ways. From the most basic open loop V/Hz control, to the more common closed loop with feedback, to KEB’s Sensorless Closed Loop, there is a control type for all applications. Both closed loop modes allow for precise speed and torque control, while the SCL can achieve this with no required feedback.

High Speed Applications

The precision of KEB’s closed loop control is especially advantageous for the high speed applications common with spindles. KEB F5 drives offer switching frequencies up to 16 kHz. Operating a spindle motor with high switching frequencies lowers motor noise, losses, and heating. The high switching frequency also allows for output frequencies up to 1600 Hz, allowing the KEB drive to control spindles up to 128,000 rpm. Pairing the F5 drive with a KEB Sine Wave Filter provides a true sinusoidal waveform for ideal motor control and efficiency, even at high speeds.

Encoder and Bus Flexibility

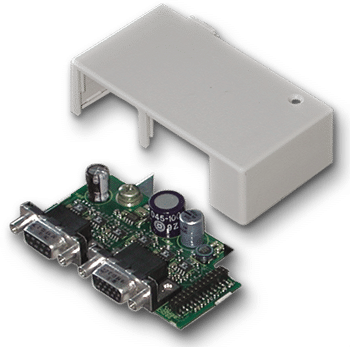

The F5 is designed for maximum flexibility for feedback and bus communications options. Both are modular and can be swapped out if another feedback or bus protocol is required, making the F5 a great fit for all systems.

In the case of the feedback board, it has two channels available for a variety of input and output combinations. Options such as TTL In/TTL Out, Resolver In/TTL Out, TTL In/TTL In, or Sin-Cos/TTL Out are all commonly used. But with over 30 combinations, the VFD can meet most feedback requirements.

The bus communication is handled by the drive’s modular keypad operator. With over a dozen supported protocols, the F5 can communicate with all major fieldbus networks. Options range from Ether CAT to Profibus to Ethernet/IP. Changing protocols is as simple as swapping out the existing operator for the operator of the required fieldbus communication. One benefit is that all internal drive settings remain the same.

Additional Control Benefits

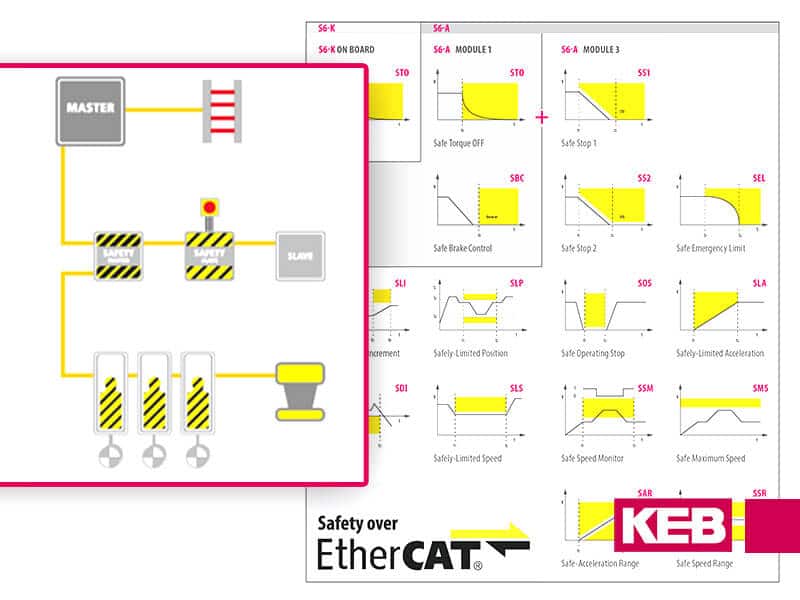

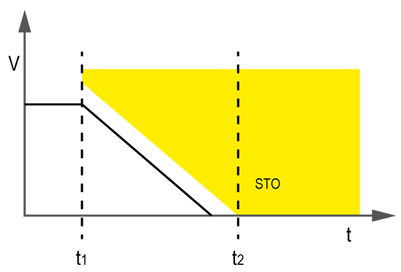

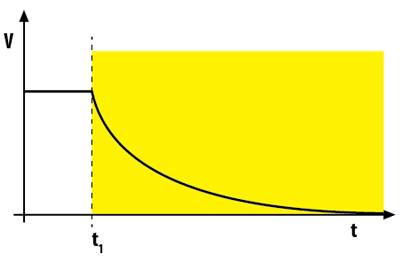

In addition to the control and flexibility already listed that makes the F5 ideal for spindle applications, it also has two options that could benefit both OEMs and end customers. The first is the added drive safety functionality of Safe Torque Off (STO) and Safe Stop Level One (SS1) in the new F5-K. The STO function is a SIL3 certified hardware/design that requires two enable inputs in order to output torque. The loss of one of the redundant inputs prevents a system from applying shaft torque. The SS1 is a function that decelerates the drive within an adjusted time before being set to STO.

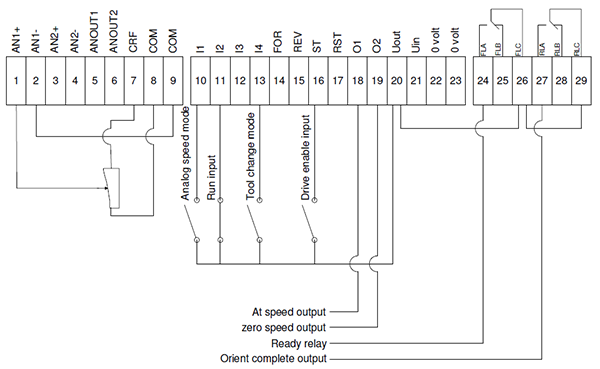

Finally, KEB offers a ready to go spindle program with both a standard run mode and a tool change/orient mode. The program is customizable to different motor data, acceleration times, or other application specific requirements. It allows for a quick and easy startup of the F5 drive with a spindle.

Power Benefits

Wide Power Range

KEB’s F5 drives also offer a variety of power benefits that make it a great fit as a spindle drive. First, the drives have a large power range, from as low as 0.5 Hp to as high as 1000 Hp. The drives also come in two voltage classes, the 230V class (Input voltage range of 180-260VAC) and the 400V class (305-528VAC). The combination of the two voltage classes and the wide power range makes it easy to find the right size drive for nearly all spindle applications.

Multiple Heatsink Options

Another power stage benefit KEB has to offer is the variety of heatsinks. While the F5’s standard air cooled heatsink is acceptable in most cases, some applications can take advantage of the through mount or liquid cooled heatsinks. The through mount heatsink allows the drive to be mounted so that the heatsink, while still attached to the back of the drive, is outside of the cabinet. This prevents the energy dissipated by the heatsink from warming up the enclosure. For additional cooling capacity, KEB offers liquid cooled drives in power sizes of 7.5 Hp and larger. The liquid cooled drives can also be through mounted, so all of the connections and piping for the liquid is outside of the cabinet and away from the electronics.

Experience with Many Motor Manufacturers

In addition to all of the benefits the F5 drive has to offer, because of KEB’s years of experience in spindle applications, we have worked with a variety of spindle manufacturers. We have worked with spindles of all power sizes from Alfred Jäger, HSD, Omlat, and a variety of others. Whether asynchronous or synchronous, KEB can run nearly any spindle as efficiently and precisely as the application requires.

There are a variety of reasons to choose KEB as the drive manufacturer for your spindle application. First, the control of the F5 drive has been proven to meet the precise speed and torque control required of spindle drives, even at speeds up to 128,000 rpm. Secondly, with an expansive power range and multiple voltage classes, KEB has the right size drive for a spindle of any power size. Finally, KEB is proven. With years of experience running spindle motors and over 100,000 installed drives running spindle motors, KEB is the spindle drive leader.

KEB Spindle Drives – When Performance Counts

If you want to know more, contact a KEB America Applications Engineer today to find the right choice for your application.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.