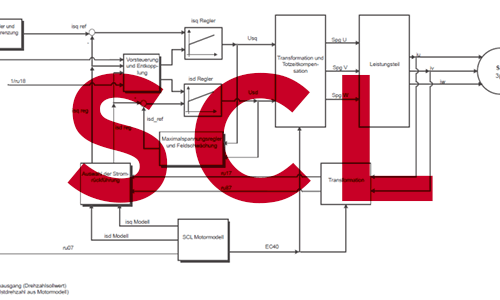

The second post, in a series of articles on KEB’s SCL technology, describes the advantages of SCL (Sensorless Closed Loop) motor control and how it fits with specific applications. The first post introduced SCL, its history at KEB, and an overview of how it works. KEB’s proprietary SCL motor control is available with all new generation drives like the S6 Servo Drive and the F6 VFD.

Sensorless Closed Loop Motor Control Advantages

SCL’s advantages are most obvious compared to other permanent magnet motor control options. The first and most basic is the standard open loop, Volts/Hertz control. This has a linear relationship between frequency (Hertz) and voltage. It works by increasing the voltage (and, in turn, the power) and proportionally increasing the drive’s output frequency/speed.

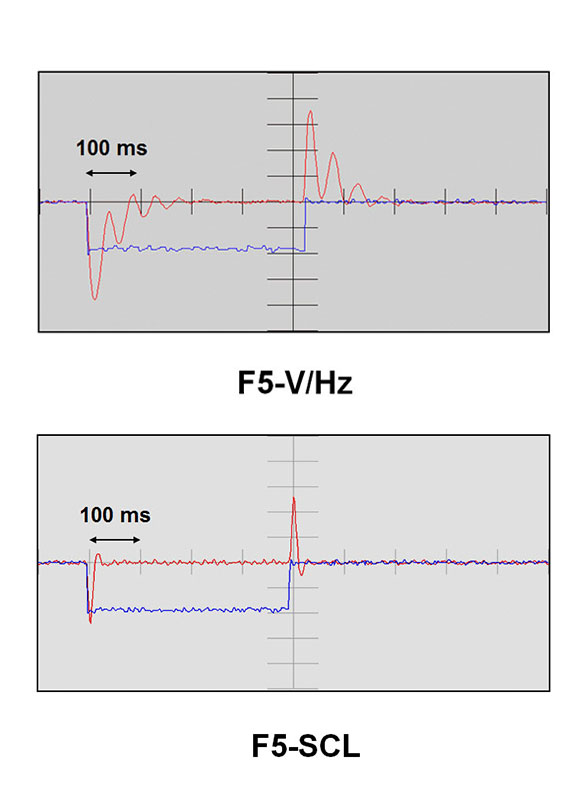

The V/Hz mode will have a constant torque until the rated frequency is reached, at that point, it will decrease with an inversely proportional relationship to the frequency. V/Hz allows for a very quick and easy startup but offers none of the advantages of SCL, such as speed/torque control or dynamic operation. An example of this can be seen in the image below.

Using the Scope function in Combivis 6, the changes in the output current (red) can be seen when both modes take an identical load step (blue). SCL responds to the load step and returns to a static output nearly 200ms faster, with far fewer current ripples. This, in turn, leads to a far more efficient operation of the motor and decreased motor heating compared to V/Hz.

The other option is to run the motor in a closed-loop mode using a speed feedback device like a resolver or encoder. In this case, the encoder provides direct position feedback that allows for positioning, such as when aligning for a tool change in a CNC spindle motor. However, SCL does offer limited positioning for applications with lower current overload requirements without requiring this feedback. The closed-loop mode with an encoder offers similar benefits as SCL over the V/Hz model, such as a highly dynamic operation.

While they have many of the same benefits, using an encoder has some downfalls compared with SCL. One of the biggest of these downfalls is cost. SCL will fit into most applications where an encoder could be used, without the added cost of the encoder and encoder cabling. The other downside of using an encoder can be concerned with the operational environment.

Sometimes due to long cabling runs, high electrical noise, vibration, or other concerns, using encoder feedback is neither practical nor reliable. Due to the limitations of the other permanent magnet motor control options, SCL is ideal for many applications.

Ideal Applications

Looking to Replace the Feedback Device or Wiring

Since its release in 2005 and over the course of its development, a few applications have arisen that are particularly well suited to take advantage of SCL. The first, and most general, is an application looking to avoid or replace an encoder. Sometimes the encoder is looking to be replaced because it is expensive or has a chance of being damaged due to a tough environment.

Other times it is the encoder wiring that is looking to be avoided due to noise or long, costly cable runs. And in other cases, it is the encoder and cable combination that lead to slow update rates that lead to better performance when switching to SCL.

Torque and Speed Control

Other ideal applications are when high torque operations are required, such as in extruders or injection molders for the plastic industry. This is because using the motor identification and model allows the SCL to provide a precise torque control compared to other motor control options.

Similarly to this, high-speed applications are also ideal fits for SCL. Examples include compressors, blowers, and spindle motors for CNC machines. All of these applications take advantage of the precise speed control provided by SCL to reach speeds of up to 64,000 rpm.

Poor Fits

While many applications can use the benefits of SCL to their advantage, not all applications are ideally suited to use it. These applications would offer better performance while using KEB inverters with encoder feedback.

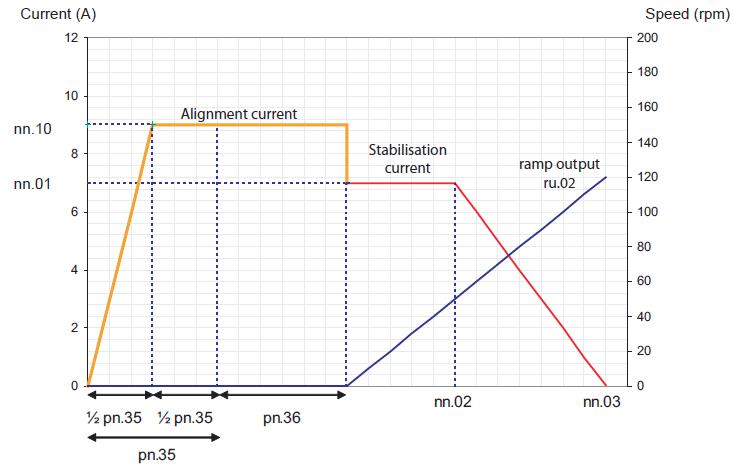

The first is applications that require high torque at low speeds or a holding torque at zero speed, such as Elevator or hoisting applications. This is because the rotor aligns to a defined position with each SCL switch-on of the modulation. Because of this, a low torque load is required at startup. The SCL startup procedure can be seen in the image below. The drive first outputs an alignment current to align the rotor with its starting position. Once that is complete, it then ramps up to its command speed.

Other applications that would not be ideally suited to use SCL would be those that consistently run at less than 1% of the motor’s rated speed. While the motor model is very precise at most speeds, it does have instabilities when running at less than 1% of the rated speed because it relies on rotor speed for feedback.

Finally, while SCL does have limited positioning functionality, if an application requires positioning and high current overload requirements, it would be better suited to use encoder feedback.

Experience the Benefits of SCL

Do you want to discuss the benefits of using KEB’s SCL technology for your application? Contact a KEB America Application Engineer today!

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.