Double C Face Brakes – How they Work

KEB Double C-Face brakes provide spring-set power-off braking and are electrically released. The brakes are packaged in a NEMA 4 rated double c-face housing which allows the brakes to be easily added to standard c-face motors.

VIDEO TRANSCRIPT

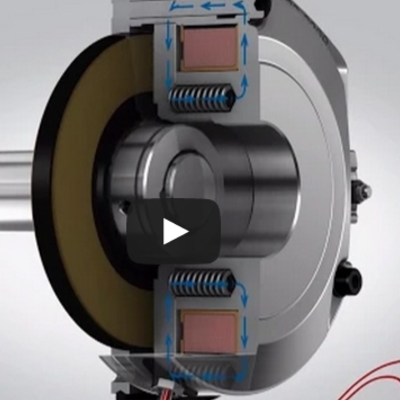

KEB’s Type 17 brake is a spring-applied power-off brake which is contained in a double c-face housing. One advantage of the KEB double c-face brake is its easy assembly to a standard NEMA C-Face motor.

First, the motor shaft is inserted into the brake’s input sleeve. Next, the brake’s output shaft is inserted into a gearbox with a standard quill style c-face input.

Here’s how the brake works. When a DC voltage is applied to the magnet coil, a magnetic field is created. The magnetic force pulls an armature across a small airgap and compresses multiple springs embedded in the magnet housing. Alternatively, without power, a hand-release can be pulled back to pull in the armature and release the brake. This option is popular for maintenance purposes.

With the armature pulled in flat against the magnet face, the torque from the motor input is transmitted through the brake to the output shaft and gearbox. With the brake powered and released, work is done on the elevator or machine.

When power is released from the coil the springs push against the armature. The friction lining is then squeezed between the armature and a secondary friction plate and a brake torque is created. Since the lining is connected to the brake output shaft with a splined connection the output shaft is locked and unable to rotate.

KEB Double C Face Brakes come in a variety of sizes and mounting options.

Looking for a generic spring applied brake for general mounting? – Check out KEB’s Combistop Spring Applied Brakes.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.