For basic machine control and visualization, KEB’s HMI LC (Logic Controller) is the preferred choice. The HMI LC combines KEB’s popular HMI product with an EtherCAT master. It is capable of managing the machine’s motion control sequences and offers expandable I/O.

This article describes a few advantages to using KEB’s HMI LC.

All-in-one Solution

The HMI LC combines what were traditionally 2 independent control products (the HMI and PLC) into one. The main advantage here is cost savings and a smaller physical footprint. A user could expect roughly a 50% savings when implementing the HMI LC over two independent devices. For many machines, the HMI LC provides enough control to comfortably handle the application. A micro-UPS is also included in the HMI LC which protects critical data in the event of a power loss.

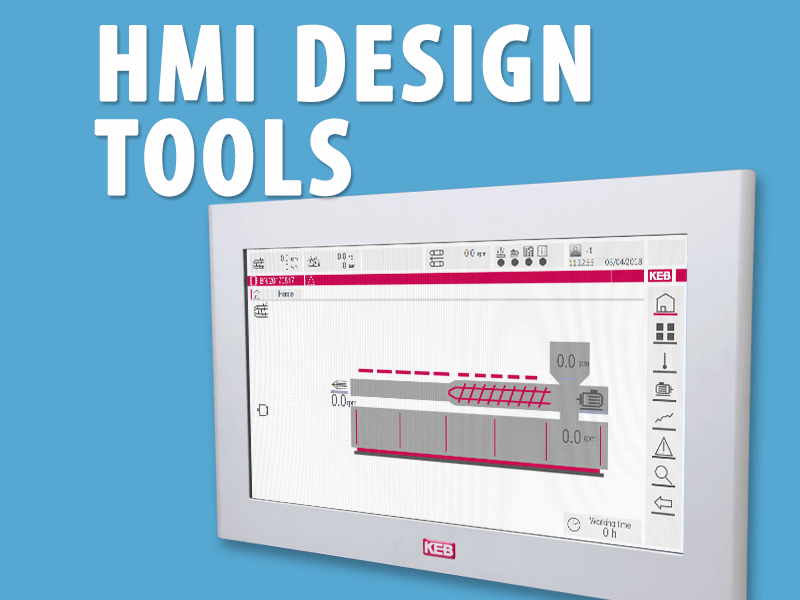

High-Quality Visualization

The HMI LC uses the same high quality (16M colors) and high luminance (~400cd/m) displays as the HMI product line. The screens are offered in both 4:3 and 16:9 aspect ratios and range in size from 5.7″ up to 15.6″. The HMI LC screens are programmed with KEB’s powerful Combivis Studio HMI program. The graphics easily scale for different size screens so only one development is needed.

The quality of the HMI LC construction is easy to see. It features an aluminum front bezel (not plastic) which is rated IP66K from the front. The unit is powered with 24VDC and contains no fans or moving parts. 4GB of solid state memory is available for the control program.

Logic Controller (LC) using Combivis 6 Studio

All logic programming is done with KEB’s Combivis 6 Studio software which allows the machine program to be developed in 5 different IEC61131-3 compliant languages including ladder logic, function block, structured text, etc. KEB ready-made function blocks are available and can be used to easily set-up different machine functionalities like master/slave and winding/tensioning controls. The included KEB function blocks and sample projects reduce the required programming time and costs.

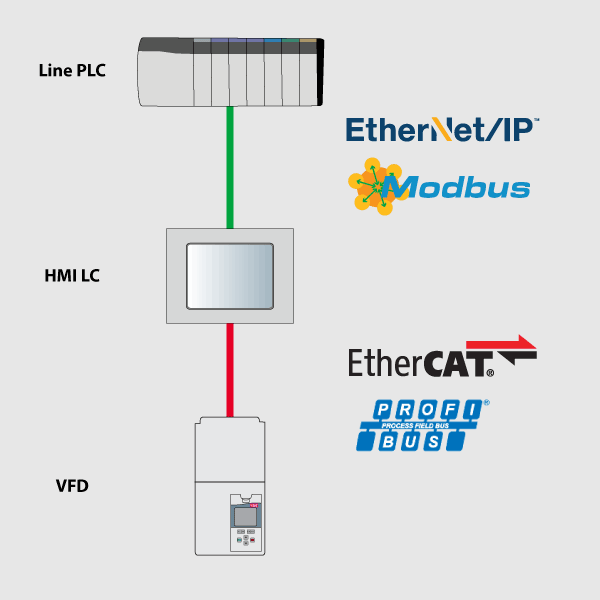

Drivers supporting 3rd party protocols

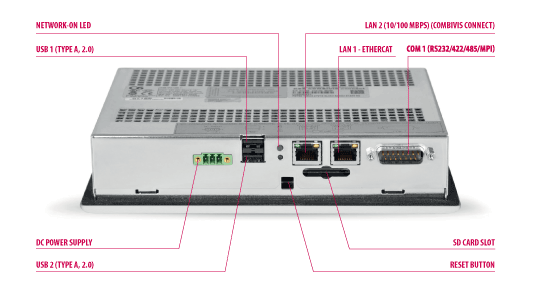

The HMI LC supports 40+ drivers which enables it to be integrated with most 3rd party controls. This allows the HMI LC to also be implemented as an HMI Gateway between different protocols.

A sampling of drivers is below (full driver list):

- KEB – PLC HANDLER (Elau, Parker…)

- KEB – DIN66019II

- Rockwell DF1 and Data Highway

- Rockwell Ethernet IP

- B&R PVI with protocol INA2000 (1)

- BACNET IP (2)

- Beckhoff Twincat (ADS protocol) (3)

- CANOpen Master NETcoreX CANOpen Master

- CANOpen Slave solo PDO NETcoreX CANOpen Slave

- Modbus RTU Master / Slave

- Modbus TCP IP

- Modbus TCP Server

- SIEMENS MPI PC ADAPTER

- SIEMENS S7 200 PPI

- SIEMENS S7 300/400 MPI

- SIEMENS S7 TCP 300/400/1200 (4)

- SIEMENS SAPI S7 SIEMENS CP5611, 5613, 5614, 5412 e SIMATIC NET

Archiving and Copying

Either a USB port or SD card slot can be used to archive and save projects. Alternatively, the ports can be used to download projects. An example of this would be if an older unit in the field needs to be replaced with a new unit. The machine program can be easily transferred with the machine functioning in only a few minutes.

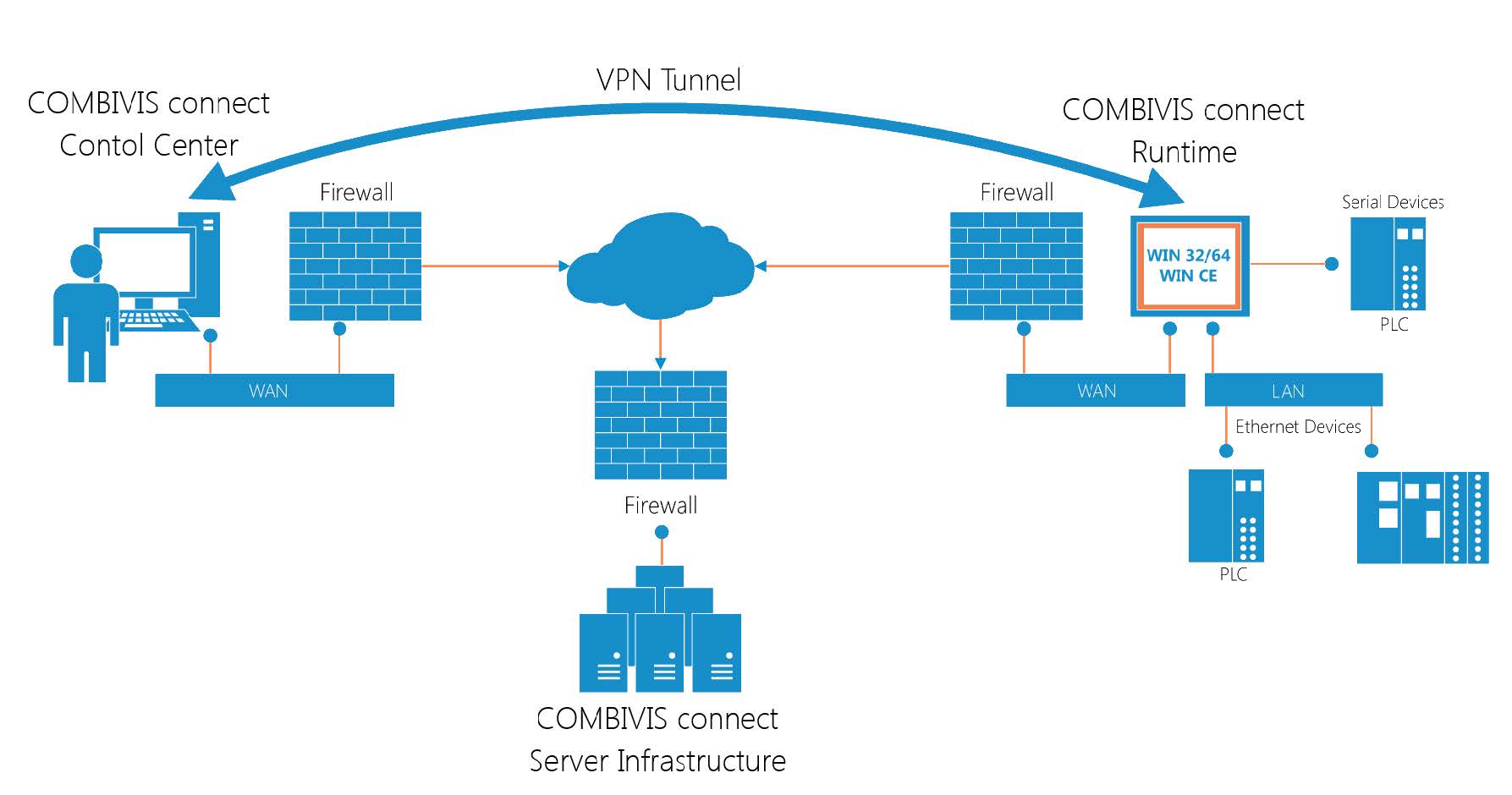

Remote Connection

Every HMI LC ships with a KEB CONNECT device license – it is included at no extra charge. The KEB CONNECT license allows the HMI to be remotely connected to through an internet connection. This opens up the possibility of remote field service, data logging, and trending analysis. This “free” feature could pay for the entire unit if it avoided one service trip.

HMI LC – An Excellent Value for Machine Builders

Are you interested in evaluating an HMI LC to see if it’s right for your machine? Contact a KEB America controls engineer today to discuss or fill out the form below.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.