Conveyor Motor Testing – Using KEB’s SCL control for PM Servo Motors

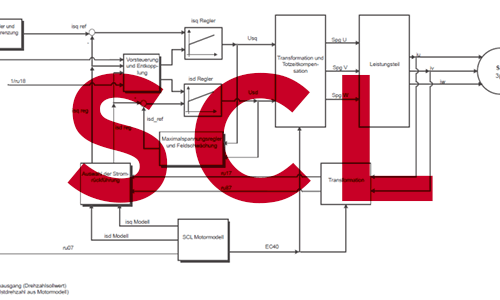

This video shows our S6 servo drive operating a conveyor motor. We are using our SCL (Sensorless Closed Loop) motor control technology.

SCL provides accurate position, speed, and torque control of a permanent magnet servo motor without the use of a traditional feedback device (encoder or resolver). The testing was done at KEB America’s R&D lab outside Minneapolis, MN.

[VIDEO TRANSCRIPT]

Welcome to the R&D facility here at KEB America. In addition to the in-house testing we can do for product development, we can also offer motor testing for customers. In this case we’ve been working on S6 motor testing with a conveyor motor. Just want to give you a quick introduction of what we’ve been doing.

So you can see over here’s the conveyor motor. You’ll notice here there’s the power cables coming out, but there’s no encoder cables. That’s because with the S6 we’re able to do the Sensorless Closed Loop or what we call SCL. That allows us to do the precise speed and torque control of closed loop without actually needing the encoder feedback.

So you can see the motor cables coming back over here and then the S6 drive. Looks a little empty because it’s a relatively simple test setup. But you can notice how the S6 with its slim profile doesn’t take up much space in the cabinet. Up here you have the power cables coming from the main line into the motor. Right here is your connector to go back to the computer to get set up with the software. And then you have all the input and output terminals. There’s a lot of digital and analog inputs on the S6 drive. This breakout board you can see here allows us to easily trigger those on and off using a test setup we have.

So then as you follow the cables back here you can see our COMBIVIS 6 software. That’s what we use to get the motor and drive started up. With the S6 drive and the other generation 6 products there’s a lot of wizards offered that allows you to quickly and easily get set up.

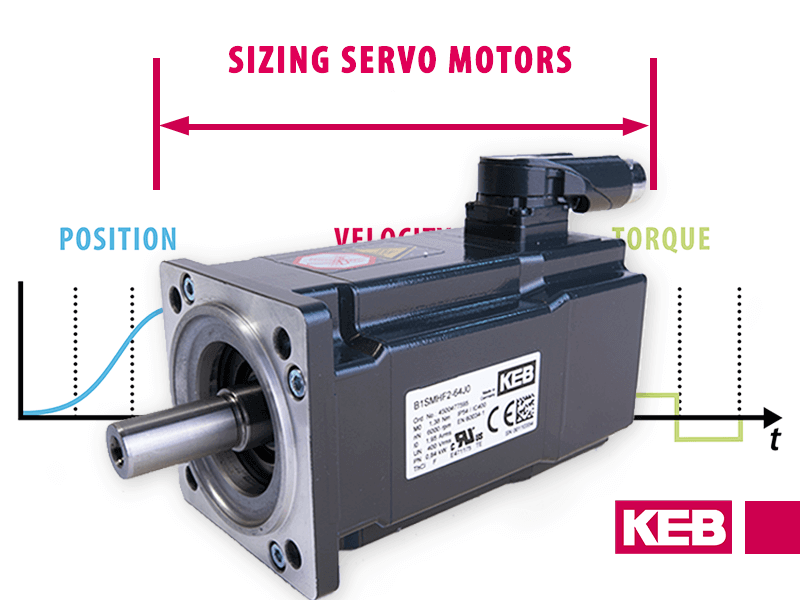

There’s the scope functionality which allows you to add up to 16 parameters in the drive and track them as you go through the operation. So you can see for instance the output current to the motor or the voltage as you’re starting, stopping, accelerating, etc. So in this application, like I said, we’re using our S6 drive to run a conveyor motor. This is a great fit for the S6 because of its high overloads. It has up to 200% overload so when the conveyor, when you’re starting and stopping so quickly, in this case you’re going up to 3000 rpm in 0.1 seconds, so that high overload is required. And then the S6 also has that SCL that I mentioned earlier. That allows for precise speed and torque and positioning control without requiring the encoder feedback. So that saves you both the cost of the encoder and the cabling. And then also, in harsh environments it allows you to eliminate the encoder if it’s in a cold storage facility, or if you’re worried about electrical noise interfering with the encoder feedback.

So that’s just kind of a general overview of the system we have here. This is a great application fit for the S6 with this conveyor motor. This drive and motor testing is just one of the additional benefits we have to offer here at KEB America.

S6 – Servo Drive

Contact a KEB America engineer to discuss your conveyor application.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.