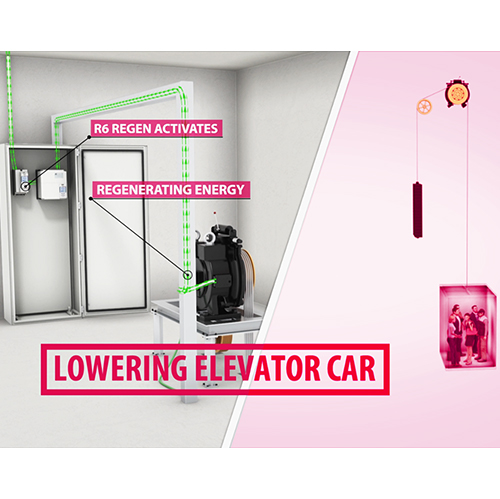

The benefits of elevator modernization – updating a system to AC gearless using KEB elevator drives and regen units – include power savings, lower noise levels, faster floor-to-floor times, and less carbon dust floating around the motor room.

DC motors were great in their day, but newer AC gearless motors offer increased performance, better power savings and the ability to regenerate excess power to put back on the building’s power grid.

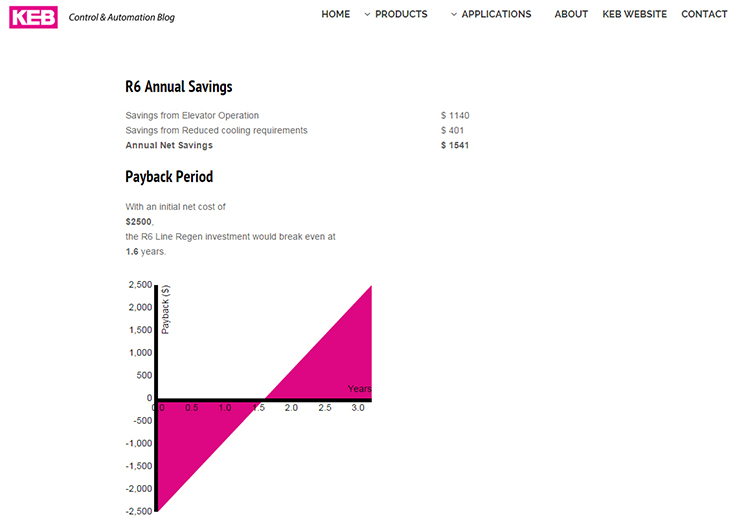

Find Your Savings – Try Our Elevator Regen Calculator

For more info on TEI Group, visit their web site teigroup.com

Elevator Modernization Video Transcript

“As everybody knows, we are all interested in the greening of our world environment and moving from DC to AC and using KEB regenerative drives affords an energy savings for the building as well as a smaller carbon footprint all around.

Ok so, my name is Wayne Locker, I’m an employee at TEI group. TEI group is a member of IUEC which is the International Union of Elevator Constructors. My key area of responsibility of TEI group is technical support for our maintenance department, modernization, and construction departments.

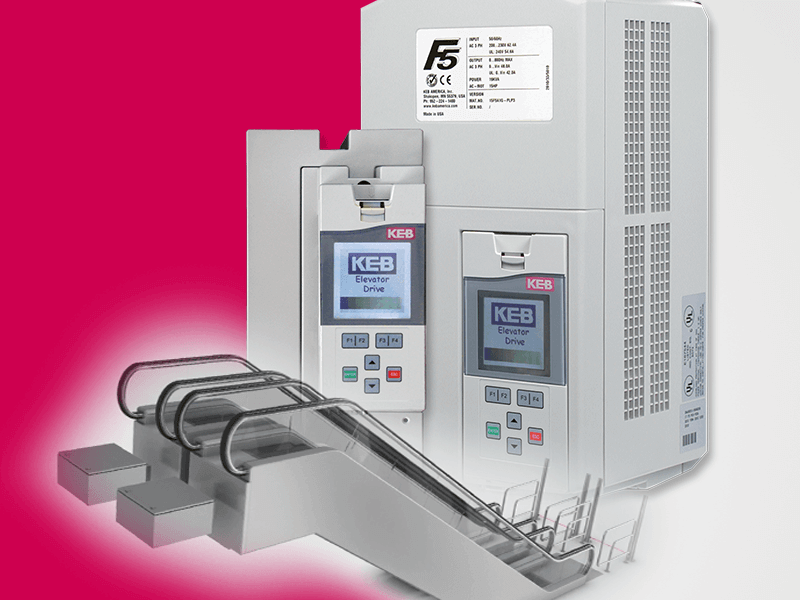

The elevators here are 600-foot-per-minute – both the high-rise and the low-rise, 24 landings total. We’ve modernized eleven cars. They were all previously a mixture of DC gearless and DC geared machines. They’ve all been modernized to AC PM gearless and the couple of DC geared cars are AC gearless induction motors all driven by GALaxy controllers and a KEB F5 Elevator drive. We also use the KEB R6 regen units to help us do a little power savings instead of dumping into a resistor.

So some of the reasons to modernize from DC equipment to AC equipment for the building owner is ease of maintenance. No more commutators, no more carbon dust floating around the machine room getting into printed circuit boards. The DC equipment was driven by motor generator sets – which were great in their day, but also are very high maintenance. Create a tremendous amount of audible noise, electrically very inefficient. Even though they do regenerate, the amount of energy used to turn them sort of negates that slightly. They also produce a tremendous amount of heat so it takes more energy to cool down the machine room. They also generate more carbon dust which also finds its way into sensitive electronic equipment and into the air that we breathe as well. The new AC PM motors are more efficient. There’s a big energy savings involved.

There are some safety mechanisms involved when you do a modernization. You are bringing up your entire elevator system to code. Some of the newer gearless machines have the secondary emergency brake already fitted onto it. With some of the older equipment it’s a little harder to fit emergency brakes on so when you do the modernization and you put an entirely new AC PM motor on it comes equipped with all the safety mechanisms that you’d require.

So here at five Penn Plaza we selected this equipment to provide the owner with a better and faster floor to floor times, more accurate and repeatable floor stops, very smooth takeoff almost un-perceptible. There’s a feature in the KEB VVVF Drive that permits us to do a fancy word like synthesized pre-torque which, when adjusted properly with the imperial machine and the brake, gives you an an almost a feel that you can’t take the car taking off. This will give the building owner and his tenants a beautiful ride quality. So in addition to the energy-saving and the ride quality were also able to reduce downtime.

Contact KEB America to learn more about our VVVF Elevator Drives.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.