This is the last of 3 posts on escalators.

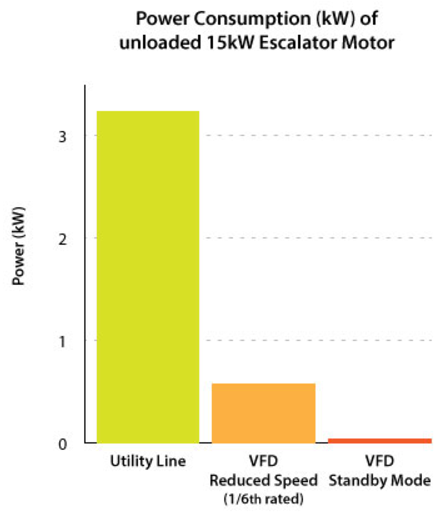

- The 1st post discusses the operational advantages using a VFD with escalators.

- The 2nd post describes the energy savings that can be achieved with VFDs in escalator applications.

This post focuses on using line regenerative drives with escalators, specifically, which escalator applications are prime candidates for regen and will provide the best payback.

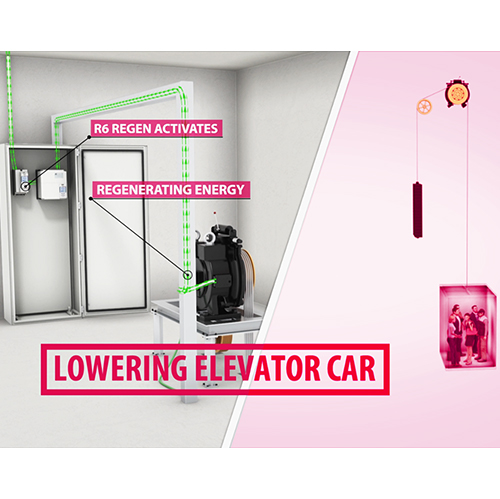

During periods where there is an overhauling load (e.g. passengers riding an escalator down), an induction motor acts as a generator and returns energy from the mechanical system to the VFD.

Traditionally, braking resistors were used with VFDs to dissipate the regenerated energy as heat. A KEB R6 Line Regenerative drive can be added to the escalator VFD through a DC bus connection as an alternative to braking resistors.

The KEB R6 unit operates by measuring the line voltage and frequency. When the escalator motor regenerates the DC bus voltage rises. Once the DC bus voltage exceeds a predetermined threshold, the R6 matches the line frequency and opens and closes its IGBTs, allowing current to flow back to the utility where it is consumed by other electrical loads.

Good Escalator Candidates for R6 Line Regen Units

Systems with a high gravitational potential energy will provide the best regen energy savings. The amount of gravitational potential energy in a system can be explained by the equation:

Gravitational Energy = mass * gravity constant * height of travel

So, the escalator characteristics that lead to relatively high regen returns will be:

- Mass – High capacity escalators that move large amounts of traffic are prime candidates for line regen. These escalators will have larger motors (20Hp +) which are sized to move the large escalator mass and people.

- Height of travel – Escalators with long travel in the downward direction are also good candidates for line regen. Longer travel means more gravitational potential energy is being converted into electrical energy.

Other system parameters which will affect line regen payback are:

- Efficiency – The efficiency of the escalator drivetrain will have a dramatic effect on the amount of regenerated energy. High efficiency (>90%) helical or bevel gearing is ideal. Low-efficiency worm gearing (<60%) provides significantly less savings with an R6 line regen unit as a sizeable amount of energy is lost in the power transmission. The efficiency of induction motors increases with larger sizes, so again, large motors (>20Hp) are well suited to be used with R6 regen units.

- Usage Profile – The amount of traffic on the escalator and the duty of the escalator will have also have a large effect on the returned energy. Subway stations and airports conveying large numbers of passengers and operating at 24/7 duty are ideal and provide the best payback. Minimally loaded escalators or those that are only used for a small amount of time will not provide a good return on investment for line regenerative systems.

Using a line regen unit instead of braking resistors provides a secondary benefit. A line regen unit creates much less heat compared to that of a braking power resistor.

Depending on where the brake power resistor is located, the extra heat might require extra cooling or possibly a larger enclosure for the escalator controller and drive. The larger enclosure, in turn, might require that the controller panel is located in a separate machine room.

Product Range

- 208-230VAC & 460-480VAC

- 50/60 Hz operation

- Graduated offerings up to 330kW

Performance & Features

- 150% current overload (for 60 seconds)

- Block commutation control scheme

- Programmable I/O

Easy Installation

- Minimal parameter adjustment required

- Automatically detects 230 or 460V connections

- Includes internal DC fuses

- Can be used with 3rd party drives

| Technical Data | |

|---|---|

| Voltage Class | 208-230V & 480V |

| Mains Frequency | 50 or 60Hz |

| Overload Capacity | 150% for 60 sec. |

| Approvals | cULus and CE |

| R6-NCM Regen Units and Chokes | |||

|---|---|---|---|

| Part Number | | Rated Supply Current (A) | | Rated Regen Current (A) | | Choke Part Number |

| 15R6N3E-R00A | | 26 | | 26 | | 15Z1B04-1000 |

| 19R6N3E-R00A | | 70 | | 65 | | 19Z1B04-1000 |

Do you want to discuss if your escalator application would be a good candidate for regen? Contact a KEB application engineer today to discuss.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.