VFD Application Notes: Flying Start and KEB’s Speed Search Technology

In this series of blog posts, we will look at some special functions available in KEB drives – like the F5 VFD or S6 Servo Drive.

This post will discuss the Speed Search or “Flying Start” function.

What is Speed Search/Flying Start?

Typical motor control applications utilize a variable frequency drive (VFD) to start the motor at zero speed. The VFD then controls the motor to the specified set speed using acceleration and deceleration rates defined in the drive.

Application conditions may result in the motor rotating while the VFD output modulation is off. For example, if the modulation to the motor is removed during the operation, the motor will be free to coast. This coasting situation may be a result of a loss of input voltage to the VFD or due to a control command of the system.

If the modulation is again initiated to the motor (main power comes back online or control system command is given, for example) and the motor is still rotating due to the inertia of the load, attempting to control the motor from zero speed may cause high mechanical vibrations, high current in the motor, and possibly damage to gearboxes or couplings.

Flying Start Function in KEB Drives

To help in this situation, KEB has developed a drive function we call Speed Search. This function is known by other names, such as Flying Start or Catch-on-the-Fly. When the Speed Search function in the KEB VFD is activated, the VFD will search for the motor’s actual speed and use this value as the starting point for the motor control, rather than zero speed. The KEB drive allows the Speed Search to be active after the main power on, at error reset, at auto-restart, or after modulation to the motor is initiated by the VFD.

Flying Start Function In Use

For example, let’s consider an application using a KEB VFD to control a motor running a large ventilation fan. In this application, the KEB VFD has the Speed Search programmed to be activated whenever the VFD is powered on. During normal operation, the building’s power is lost. Once the main power is lost, some residual power is stored in the KEB VFD capacitors so it will not power down immediately. Once the power utilized by the ventilation fan system drops the VFD DC bus to a low enough level, the KEB VFD will power down. When the KEB VFD powers down, the modulation to the motor is removed, and the fan motor is free to spin.

Depending on the inertia of the fan and the application setup, the fan may take some time before it stops. If power is restored before the fan stops, the KEB VFD will actively search for the motor’s actual speed and then use this value as the starting point for the ramp up to the commanded set speed.

In this case, the speed search function would provide a smooth control of the motor back up the set command speed minimizing any stress on the mechanical components and bring the system back to normal operation automatically.

KEB’s Speed Search can also be used when the motor rotates opposite the desired speed set point. For example, if the modulation to the motor of a blower system is removed and there is some residual pressure or backflow, this may cause the motor to rotate in the reverse direction as defined by the application.

If the modulation to the system is restored and the speed search function is activated, the KEB drive can determine the motor direction is not the same as the desired set point direction and, utilizing the protective functions of the drive, return the system to the desired setpoint speed and direction. In this case, once the KEB VFD has determined the motor speed is not in the same direction as the desired set point, utilizing the LA stop protective function of the drive, the KEB VFD first decelerates the motor to zero speed and then accelerates the motor in the forward direction to the command speed.

Comparison of Different Implementations

The speed search function of the KEB VFD in an open loop system works by monitoring the active current of the motor. The active current is the torque-producing current. The speed search function utilizes the current command frequency or the last known frequency as the starting point for determining the motor speed.

If the application control is such that the command frequency is not changed very often, then using the command frequency as the starting point for the speed search function works well. The last known frequency is a good option if the command frequency changes during operation.

When the speed search function is activated, the output frequency to the motor is set to either the command frequency or the last known frequency as programmed in the speed search options. The output voltage to the motor is then increased if the output phase current to the motor reaches the level defined in the speed search setup. The VFD then starts to lower the set frequency by the rate defined in the speed search setup. The default value of this current level is 80% of the VFD-rated current.

As the output frequency drops, the motor’s active current will increase. Once the active current stops increasing, this indicates that the output frequency of the motor matches the actual speed of the coasting motor. The KEB VFD then keeps the output frequency constant while the output voltage is increased at a rate defined in the speed search options.

The output voltage rate of increase may need to be changed if the load on the motor is such that the actual speed drops too low during the time the output voltage, and thus the motor torque, is increased. Testing system settings may have to be done to find the best solution for the application. The output frequency is kept constant for a short time, at which point the KEB VFD switches into standard operation and accelerates the system to the command speed.

Using Command Frequency

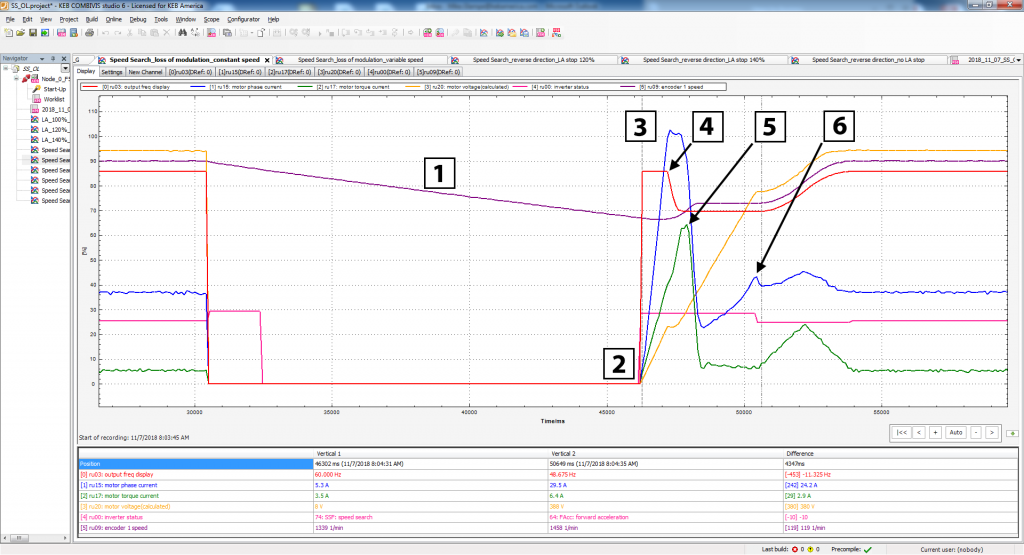

Figure 1 is a scope trace using the KEB Combivis software of the Speed Search function in operation. In this case, the modulation to the motor was shut off, allowing the motor to coast. The noted points on the graph represent the following:

1. Coasting motor speed

2. Modulation to the motor engaged, Speed Search active.

3. Output frequency (red) initially set to command frequency. As the output voltage (yellow) increases, the phase current (blue) increases. Phase current reaches the 80% level as defined in the Speed Search function.

4. Output frequency is reduced per the Speed Search setup.

5. Motor torque current (green) stops increasing. Motor speed determined.

6. Output frequency stays constant, and the output voltage is increased. After a short time, the VFD resumes normal operation and commands speed.

Figure 1 Flying Start – Command Frequency [Click to enlarge]

Using the Last Known Frequency Output

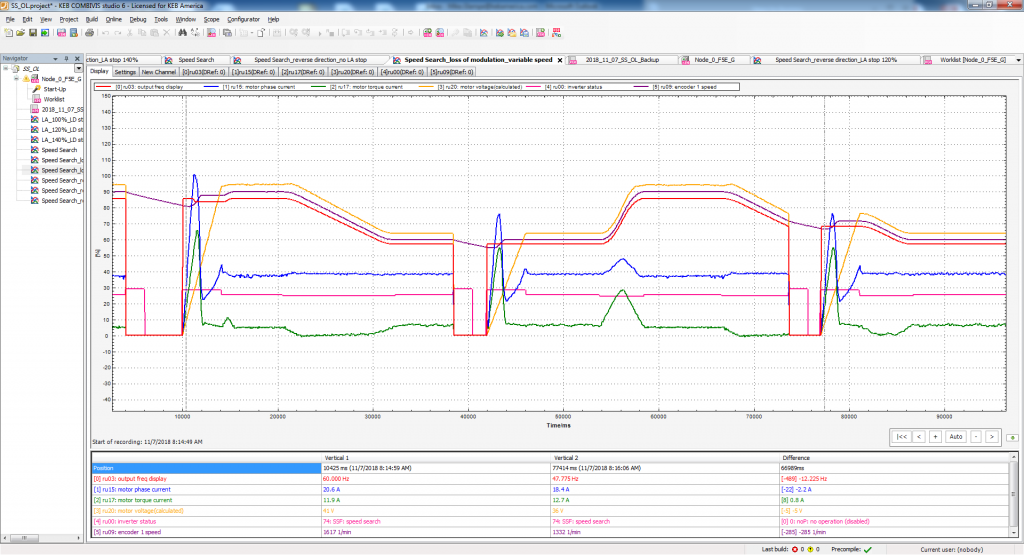

In applications that may have changing set speeds, the KEB speed search function can also be set to use the last know frequency output as the starting point for the speed search function. Depending on how long the modulation to the motor is removed, this may allow the speed search function to determine the motor speed in a timelier manner.

Figure 2 is an example of the speed search function with the last known frequency used as the starting point. Notice that in the last instance of the speed search function activating, the modulation was removed from the motor during the deceleration of the motor. The speed search then uses the last known frequency even though the system had not reached the programmed set point.

Figure 2 Flying Start – Using last known frequency [Click to enlarge]

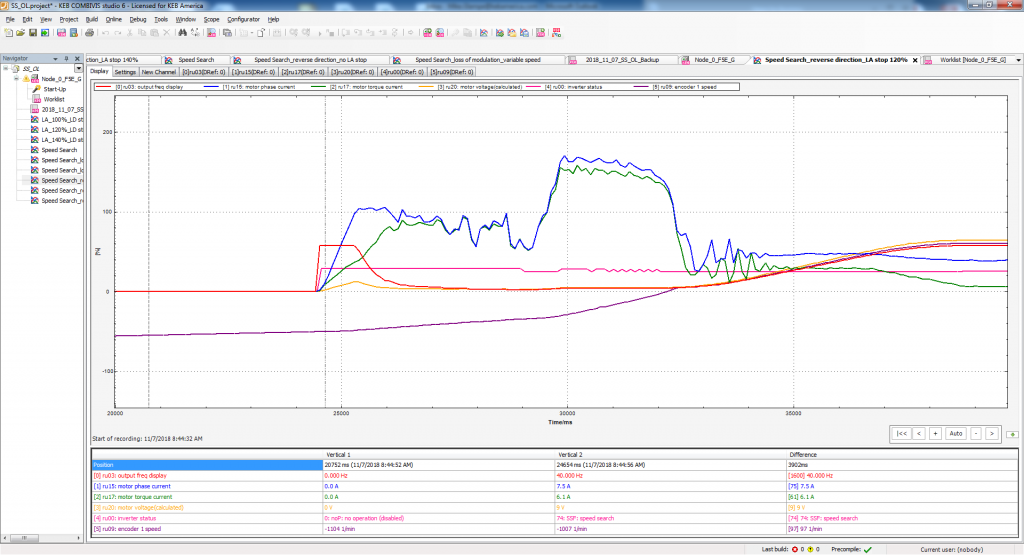

Catching a Motor Spinning in the Opposite Direction

Figure 3 shows the KEB speed search function when the motor rotates opposite the commanded set point. In this case, when the speed search function is activated, once the phase current (blue) level is reached, the output frequency (red) to the motor is reduced until the magnetizing current (green) drops.

In this case, the speed search function drops the output frequency to zero since the motor is rotating in the reverse direction from the initial starting output frequency. After a short time, the system goes into normal operation, and the current limiting functions of the drive are utilized to bring the motor to a stop and then accelerate it to the command frequency.

Figure 3 Flying Start – Catching motor from opposite direction [Click to enlarge]

Summary

The KEB speed search function is one of many powerful, standard functions available with KEB VFDs. The above examples were done in an open loop control. The KEB closed loop VFDs also have the speed search function. The function works very similarly to the open loop version, but the closed loop will utilize the measured frequency from the feedback device as the starting point for the speed search function.

Properly utilizing this function can help reduce mechanical stress on components and help reduce potential downtime of your system when momentary interruptions to the operation occur.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.