Functional safety for packaging machines, presentation at PackExpo in Las Vegas.

KEB helps packaging machinery builders build safer machines. KEB’s Functional Safety products include Safety PLCs, Safety IO, Drives with Safe Motion, Servo motors with Safe Encoders, and Spring-set brakes.

KEB’s FS control products are certified to a SIL3 level and communicate via Fail Safe over EtherCAT (FSoE).

Video Transcript:

Hi I’m Jonathan. We’re here at the PackExpo in Las Vegas. One of the highlights that we’re showing in the KEB booth is our safety solutions. I’d like to give you an overview of what we’re

showing.

So on this display behind me we have a comprehensive overview of all the safety products that KEB can provide. So we can be a single source provider for all the safety solutions. Everything from the safety PLC all the way down to the spring-set brake.

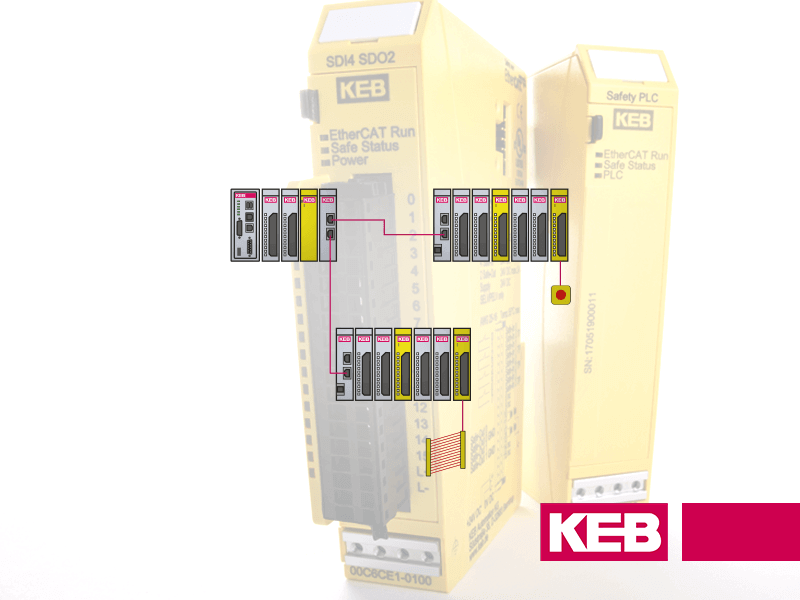

At the top we have the safety PLC, a new product for KEB. It’s a Functional Safety over EtherCAT (FSoE) PLC which pairs together with our I/O. All of the connections can be made with a

network cable. The safety PLC is programmed in a safety editor inside our COMBIVIS PLC software. This provides our customers one platform to program the machine control and the safety control. All the products, both the programming environment and the safety PLC and the I/O are certified by TUV and again the operate over FSoE bus, so this allows a lot of the older discrete wiring potentially to be replaced with network cabling.

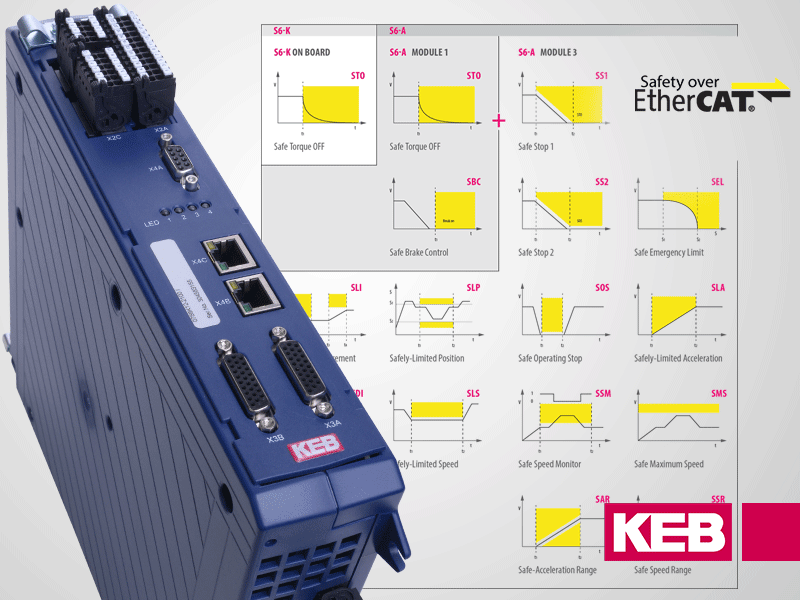

Then looking at the next layer we have our drives. So, on display we have the S6 FSoE drive. This would pair together with the safety PLC. Again, everything on the safety side can be

connected with a network cable. This allows you to pass data on safe-torque-off (STO) and some of the other functions over the network. This includes STO, but it also includes a lot of the other safe motion functions that the S6 supports, like safe-limited-position or safe-limited-speed, and that’s what we’re showing here are the number of different safe motion functions that are supported by the S6. This is big because it allows a lot of the wiring to be reduced to the network cable, which increases diagnostics and also reaction time.

Continuing further down are KEB servo motors. So our servo motors optionally can be equipped with safe encoders, which then tie back into the drive. Additionally, with the safe encoders we can

apply a safety brake. A fail-safe brake on the servo motor, which is a little bit of a unique offering that is our own brake technology, and that’s also then what we’re highlighting.

At the very bottom of the display is our spring-set brakes. These brakes can be used in cranes or hoist, press-type applications, anything that safety’s critical and you need fail-safe braking.

If you have any more questions you can contact us or check out the links below.

Thanks.

If you have questions about our safety for packaging machines solutions or any other control and automation products from KEB America, please drop us a note.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.