Fieldbus, Ethernet, Wireless: Who leads in the global communication network?

Earlier this year, communications protocol experts HMS Industrial Network released their most recent findings regarding the market share of the most popular communication network protocols. What does this mean for your installations? Let’s dig into the data and get our take on the future of communication and how it relates to automation and control products.

The first thing to recognize from these findings, which HMS gathered from its sales reports and insights into the industry, is that all types of installations are on the rise. With the growth of the Industrial Internet of Things (IIoT), or Industry 4.0, a strong communications network is key to the success and longevity of a company or product. Fieldbus, which no longer has the largest share, rose approximately 7% over the last year, Ethernet grew 20%, and wireless saw a 30% increase in total installations. According to HMS, 2016 is the first year they’ve seen wireless – WLAN, Bluetooth, etc. – have a significant market share.

Reading the report

PROFIBUS, developed in the late 1980s by the Federal Ministry of Education and Research in Germany, has the largest number of installations. That said, Ethernet technologies are starting to take up a larger portion of the pie. After PROFIBUS’s share is Ethernet/IP in second place and PROFINET in third, demonstrating the industry’s shift to embrace industrial Ethernet.

Although wireless networks only make up a small portion of the total market – WLAN at 2%, Bluetooth at 1%, and all other wireless types at 1% – this is the first time they’ve been seen in enough installations to affect the total number of sales.

“We see the Internet of Things as being a big driver for wireless technologies,” said HMS marketing director Anders Hansson in an article published by Drives & Controls magazine. As the modern workplace becomes more distributed, customers begin to expect the ability to control their devices via wireless technology on laptops, tablets, or smartphones. Increased installations of wireless communication networks mean engineers no longer need to be on-site to troubleshoot and repair many types of automation devices.

IoT and the shaping of communication network trends

In any conversation where we discuss today’s innovative products and services, you’ll hear things like IIoT, Industry 4.0, SaaS, Cloud Services, and Big Data. Most of the time, this is simply called The Internet of Things. The idea that nearly every new product or service is connected to the Internet or some kind of network or cloud brings to mind the idea of refrigerators with Twitter apps or wristbands that store their wearer’s sleep patterns in a database. IoT applications have a place in the consumer goods and entertainment market to sell a customer a product that, in return, can supply you with a steady stream of income – as long as the client continues to use the service associated with that product. The Consumer Electronics Show in January of this year had many examples of how IoT allows a company to provide a service in addition to a device.

Data exchange and automation are completed via industrial networks to make running distributed installations much more cost- and time-effective, to allow for Bring Your Own Device workplaces, and to gather more complete data about installations in real time. Cyber-physical systems (or embedded systems) are finding their way into many industries with global distribution.

When a technology explodes in popularity as IIoT and Industry 4.0 have, one of the biggest challenges faced by manufacturers, end-users, and everyone in between is interoperability. Standards for specific industries and use cases do exist. Still, a manufacturer or designer shouldn’t limit the reach of their product by the exclusive use of one type of communication protocol.

Communication options for a more versatile network

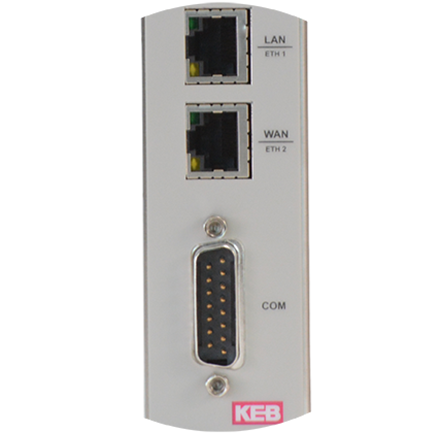

When we design products here at KEB, we want our customers to be able to integrate them into their existing installations quickly and easily. A KEB drive, like the popular F5 high-performance VFD, can communicate over Powerlink, EtherCAT, Ethernet/IP, Ethernet TCP/IP, Profinet, Modbus, Profibus, DeviceNet, CANopen, Interbus, and Sercos. Because we’re always keeping an eye on the emerging trends and consumer demand, our new C6 Router adds 2G/3G/3G+ for wireless implementation.

In addition to robust industrial communication hardware, KEB has software that is useful for setting up a network through our global server. By installing COMBIVIS Connect on a remote user’s system, you can monitor installations and troubleshoot bugs via a secure VPN connection. With COMBIVIS HMI, you can build a graphical interface for the systems you are monitoring for better visualization.

We expect to see more innovation in networking and communication as IIoT and Industry 4.0 gain traction in many industries. It’s important to keep an eye on these trends and get feedback from our customers and our peers in the industrial manufacturing industry so we can continue to provide products that know how to communicate with speed, security, and reliability. If you have any comments on the future of networked communication, leave us a comment below.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.