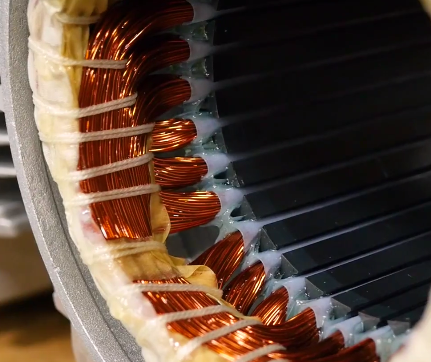

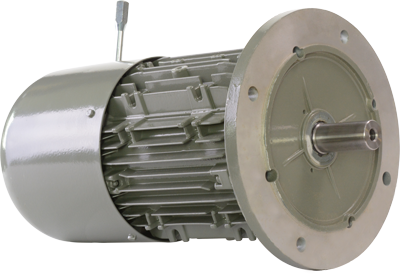

KEB has years of experience providing high-quality, long-lasting gearmotors for packaging applications. We offer a wide range of motor and gearbox combinations with numerous mounting and protection options allowing you to customize the selection that best fits your application. Our gearmotors combine high-quality German engineering with local assembly and customization ensuring timely delivery and a product well suited for the North American market.

Gearing Configurations

KEB offers five gearing configurations. Two of the most commonly specified in the packaging industry are:

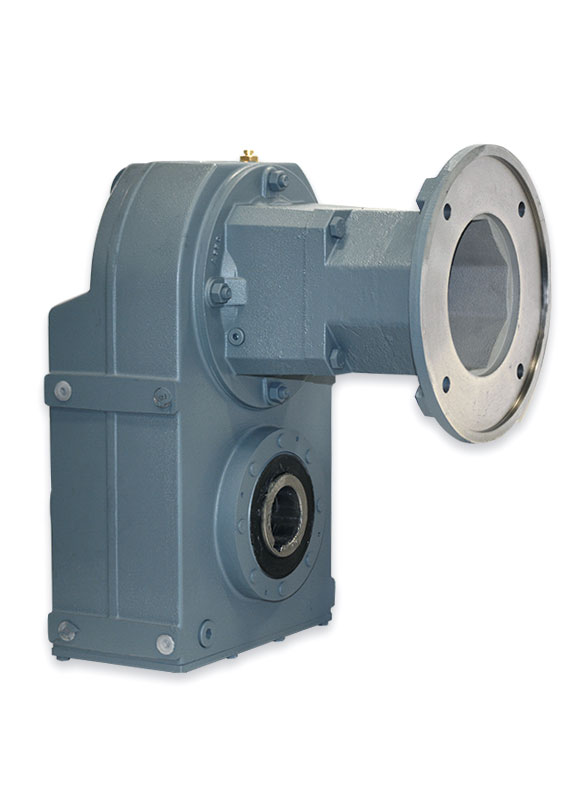

Helical Bevel – providing a right angle output and a high-efficiency gearbox (94-96%); perfect choice for economical conveyor-type applications. KEB’s high-quality gearing is prepared to DIN 3990 specifications. Gearboxes are available with solid or hollow output shafts.

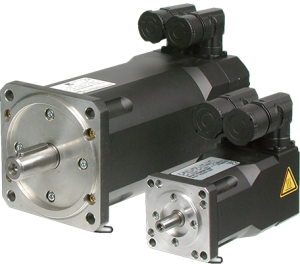

Planetary – inline or right angle with integer gear ratios, low backlash, high torque density, and high efficiency (97%+); perfect for precision applications requiring tight positioning control. Our planetary gearing has multiple output shaft options, and lifetime lubrication, and pairs perfectly with a KEB servo motor.

Other gearing configurations offered by KEB include: Helical Inline, Helical Offset, and Helical Worm

IP65+ and Food Grade Solutions

KEB gearmotors can be provided with extra seals, epoxy, and protective paint for use in washdown applications. Our SteelIT solution is a great option for an economical washdown solution. Motors can also be supplied with food-grade lubricants. This makes them an extremely durable yet economical solution for washdown and food-grade applications that don’t require a full SST solution.

KEB’s helical offset gearbox is a great space saver for tight applications allowing the output shaft to come back alongside the motor

Gearbox Only Solutions

If you already have a preferred motor supplier, KEB can only provide the gearbox with various options for the input configuration. Both NEMA and IEC inputs are available, along with inputs for servo motors.

Flexible Gearmotor Configurations

No matter which type of gearing you choose, KEB gearmotors are extremely flexible and customizable. They can be prepared with special flanges, output shafts, bearings, shrink discs, shaft couplers, encoders, etc. Various electrical connectors (e.g., Harting connectors) can be provided for easy installation and quick connect/disconnect for applications with difficult wire routing. Terminal box and power connection locations can also be configured to your application’s needs.

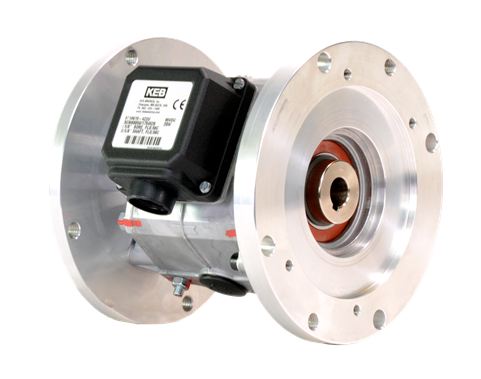

Shafts can be prepared for an encoder and/or brake, or supplied with a KEB encoder and spring-applied brake. KEB spring-applied brakes are very flexible with options including manual hand release, microswitch for engagement verification and/or wear monitoring, high energy friction linings for applications requiring repeated stops of large loads, and IP65 protection for washdown or outdoor applications, along with many more options.

With over 45 years of experience making spring-applied motor brakes, KEB offers just about any configuration you could require to pair with our gearmotors.

KEB – Your Motor Partner for Packaging Machinery

KEB’s high-quality, customizable solutions allow us to handle nearly any gearmotor needs you might have. We are excited to partner with you for your next application!

If you’d like to learn more about KEB gearmotors for packaging applications please contact a KEB sales engineer today.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.