Helical Bevel Gearmotors

KEB offers several gearmotor options. In my experience, the most popular option is the helical bevel gearing. The combination of high efficiency, versatile performance, and great pricing makes the helical bevel gearmotor an ideal solution for applications where an angular continuously high output torque is required.

Worm Gearing vs Helical Bevel

Often times people think that worm gearmotors are the better option because they can achieve the desired output speed and torque for an application at a lower price. However, a drawback to worm gearmotors is the less efficient operation when compared to helical bevel gearmotors. In fact, worm gearing is one of the least efficient types of gearing. You will find that worm gear efficiency is often times around 80%, but KEB’s helical bevel gearmotors are 90+% efficient. The higher efficiency comes with other benefits, such as less heating and less audible noise when compared to worm gearing. Additionally, you can use a smaller motor for a given output torque.

Watch: 5 Types of Gearing

Upfront Cost vs Lifetime Cost

Although initial cost may be higher for the helical bevel gearmotors, the long term operation costs will be more for you if you select a worm gearmotor. due to the fact that you will be paying much higher energy costs since the worm gearmotor is less efficient than the KEB helical bevel gearmotor.

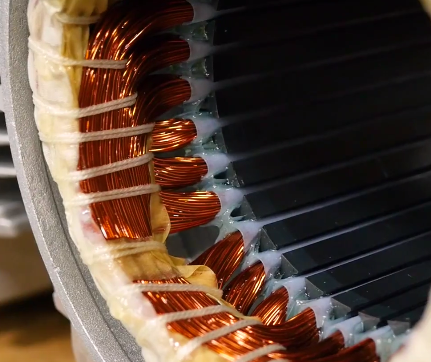

IE3 Efficiency Standards

The rising energy costs have been a big topic recently, and it looks like it will continue. Governments have long understood that electric motors are a large consumer of electrical energy globally and have been working to adopt legislation to increase motor efficiency. KEB understands the changing landscape and has made electromagnetic changes to the stator windings to meet the higher IE efficiency requirements in Europe, North America.

Read More: Addressing the Energy Crisis Through Motor Efficiency

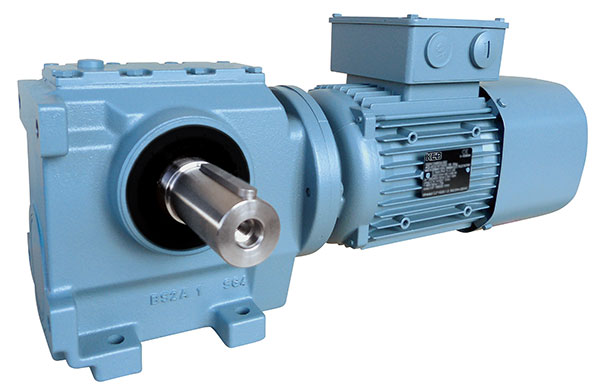

KEB Helical Bevel gearing with a solid shaft keyed output

Sizes available

KEB’s helical bevel gearmotors are available from .25hp – 50hp and we offer many complimenting options/add-ons for whatever your application may require.

Applications for Helical Bevel Type Gearmotors

Typical applications for our helical bevel gearmotors include industrial door lifts, theatre hoists, and cable drum driving. Our gearmotors can be mounted by either foot or flange mount, and we can machine custom flanges to fit your application needs. The bevel gearing provides a right angle output. We offer hollow shaft outputs as well as a variety of custom machined solid output shafts.

Brake Solutions for Gearmotors

We can add our spring applied brake solution to the non-drive end of the motor for applications where dynamic braking is needed, or for applications where a secondary holding brake is needed. We can even mount a load brake onto the output of a helical bevel gear motor for hoist and theatre applications. For applications where strict positioning is needed, we offer both incremental and absolute encoders, and for those washdown applications, we offer an IP65 rated gearmotor solution.

If you’d like to know more about our helical bevel gearmotors contact a KEB sales engineer via email.

Here’s a short video if you’d like to know more about our gearmotors and production capabilities:

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.