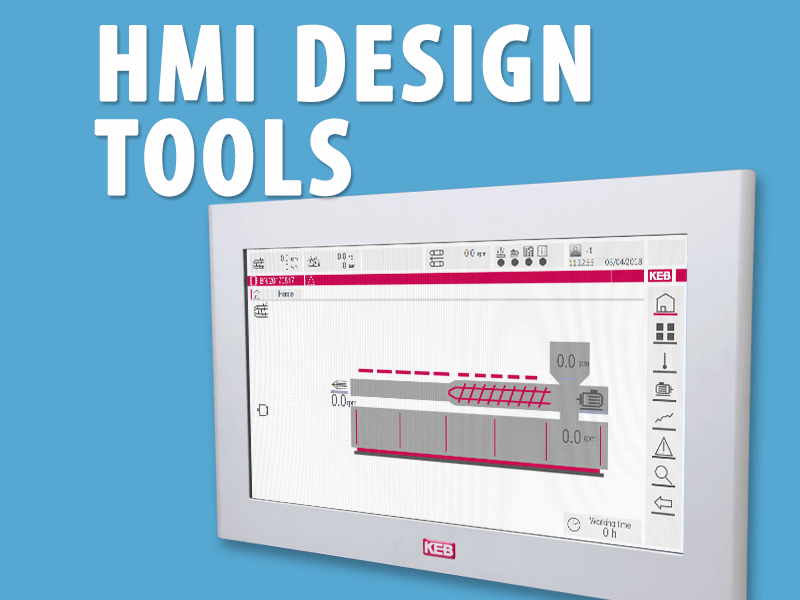

Combivis Studio HMI is a design tool used to create graphical user interfaces and monitoring systems for KEB’s industrial visualization products. It empowers design engineers to create scalable and fully featured visualizations in a time-effective manner. Built upon open communication standards, Combivis Studio HMI ensures complete connectivity with the automation system using a vast communications driver database. This article will serve as an introduction to the benefits and features of Combivis Studio HMI.

Intuitive Environment with Drag and Drop Design Principles

The first and often biggest hurdle to overcome when using development software is learning the environment and feeling comfortable with the tools available. Combivis Studio HMI is a windows-based tool that allows programmers to easily customize the programming interface for ease of use. Windows containing common tools can be easily docked for easy access.

This video is a walk-through of how to design HMI screen navigation from start to finish using KEB COMBIVIS software.

Combivis Studio HMI contains an extensive toolbox of graphical objects such as buttons, switches, gauges etc. for high-quality screens. Each object has a large number of predefined properties and actions which can be easily accessed with drag and drop techniques. This means tags can easily control graphical objects by simply dragging and dropping a tag onto specified graphics. In addition all graphical objects can be copied, cut, and pasted to save time with repetitive tasks.

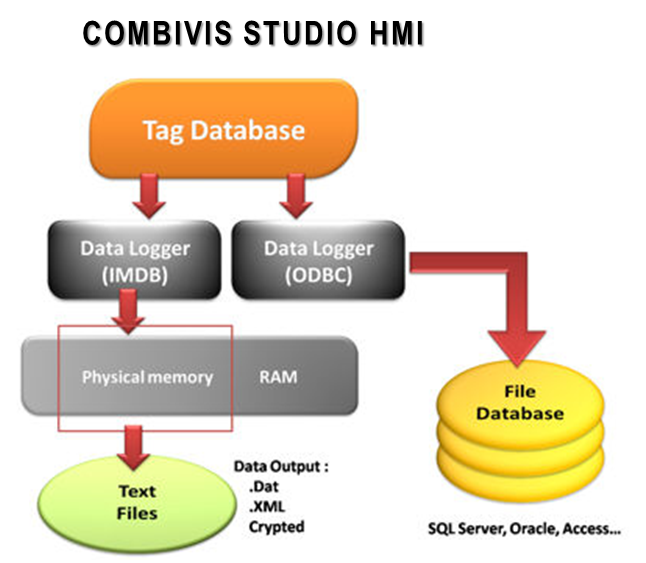

Powerful Data Recording and Management

Data logging, recipe management, alarms, and real-time trending allow users to record and manage data from machines and processes for analysis. Each of these features is standard with Combivis HMI Studio, allowing users to make data driven decisions without added cost. Is it possible to extract data for analysis outside of the plant floor, for further statistical analysis? YES, the HMI projects allow data to be logged to the physical memory of the HMI (In Memory Data Base) as a file or to an external data base (Open Data Base). Database types supported include MS SQL, MS Access, Oracle Express and more.

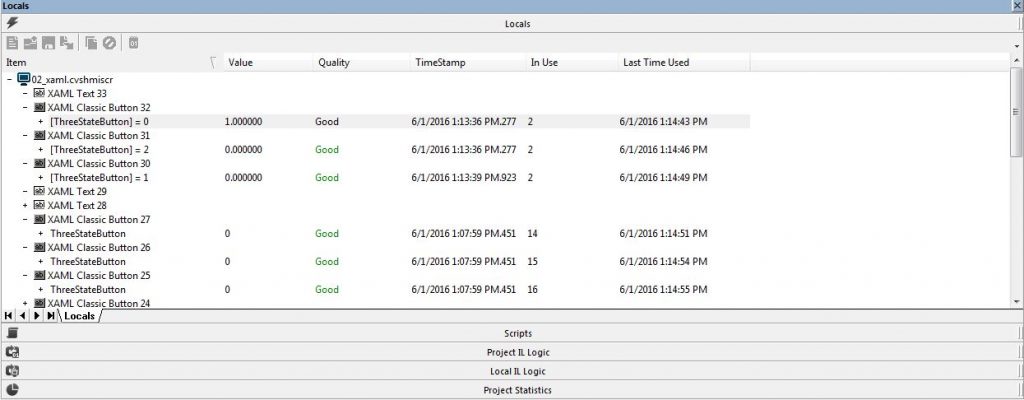

Decrease Debug Time and Increase Performance

Project testing and debugging is an important phase of development. The debug mode enables designers to conveniently simulate the runtime of its HMI and watch variable statuses, system statistics, and project logic. Project iterations are faster with fault searching and performance watching.

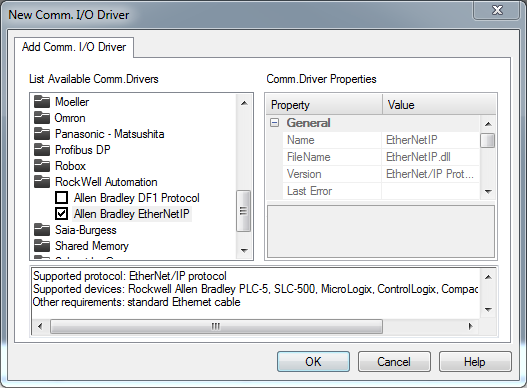

Open Communications Driver Database

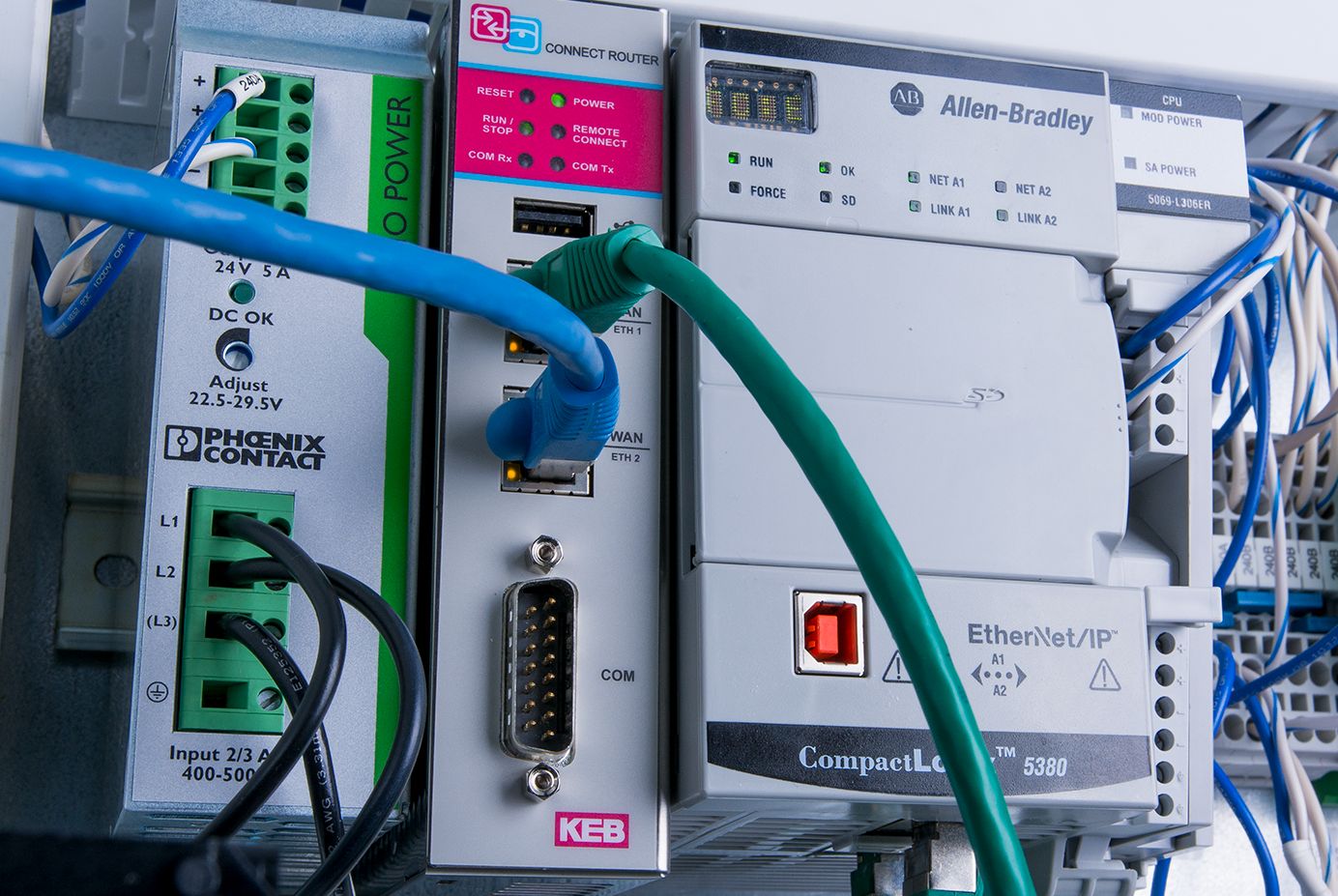

KEB HMI’s can be integrated with 3rd party PLC’s using a large database of PLC communication drivers. Importing tags from an existing database is simple regardless of if you are using a KEB PLC or not. A sampling of available drivers includes:

- KEB PLC Handler (Ethernet)

- KEB DIN66019II (Serial)

- Rockwell DF1 and Data Highway

- Rockwell Ethernet IP

- Beckhoff TwinCAT (ADS Protocol)

- CANOpen Master

- CANOpen Slave

- GE Fanuc

- Modbus RTU Master/Slave

- Modbus TCP IP

- Omron Host Link

- Siemens S5 CPU, DK3864R

- Siemens S7 200 PPI, 300/400 MPI

- Siemens S7 CP 300/400/1200

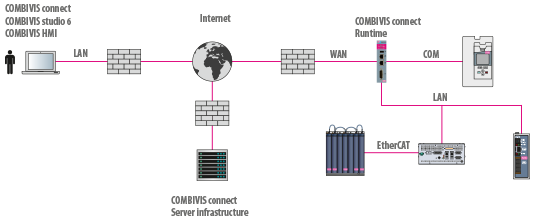

VPN Remote Connections

Software always requires improvements and fixes once in production. Combivis Studio HMI is integrated with Combivis Connect using commands which can be used to handle remote VPN connections for monitoring of HMI projects. The running HMI project can be seen anywhere in the world as long as the remote user has Combivis Connect. Additionally time and money can be saved trying to troubleshoot bugs and reduce service trips.

If you’d like to hear more about Combivis HMI or how you can download a free copy of our software, contact a KEB America engineer, or fill out the form below

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.