Electromagnetic Clutch – How It Works

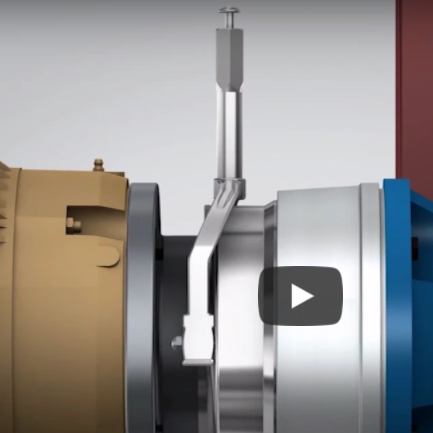

This video describes how KEB electromagnetic clutches operate. KEB clutches are electrically engaged and allow a friction connection between two shafts.

VIDEO TRANSCRIPT

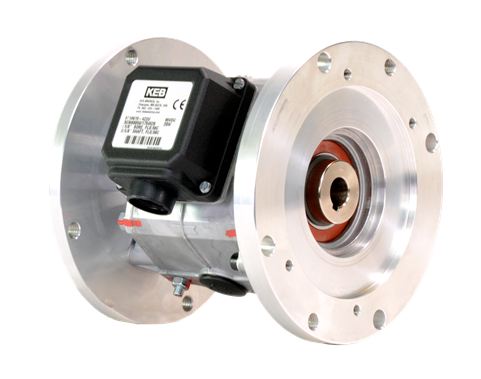

KEB’s Combinorm Electromagnetic Clutch allows power to be transferred from a primary drive shaft to a secondary load shaft. The Combinorm clutch product is electrically engaged and can be configured in inline or offset configurations. KEB or customer supplied hubs and pulleys can be incorporated into the clutch along with integrated bearings.

First, let’s get acquainted with the main clutch components. The primary drive shaft typically contains a stationary electromagnet which is fixed with a flange or torque tab. A rotor is fixed to the primary driving shaft with a key or other connection. Next, an armature is riveted to a flat spring. The flat spring is then riveted or screwed to a hub, or in this case, a pulley, which is then connected to a secondary shaft with a belt.

Here’s how the clutch works. When a DC voltage is applied to the electromagnet coil a magnetic field is created. The magnetic circuit passes through the clutch rotor and armature. The force is large enough to deflect the flat spring and the armature is pulled across a small air gap into the rotor face. The friction between the rotor and armature allow the driving shaft and armature to rotate at the same speed. When electrical power is removed from the coil the flat spring returns and pulls back the armature. Without a friction connection the two shafts rotate independently.

For more information about KEB electromagnetic clutches, visit our Clutch Product Page.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.