How to Use Combivis 6 Scope Trace and Start-up Wizards

An important but often overlooked aspect of choosing an inverter for an AC motor application is the corresponding software that will be used to program it. If the software is too basic or too difficult to use, the programming/commissioning process may feel impossible. This can lead to lost weeks (or even months) in development to figure out how to operate the device.

Combivis 6 is KEB’s free and intuitive software tool for programming and commissioning inverters. With Combivis, the user can have a running motor in minutes, even with minimal inverter programming experience. It allows the user to view and/or modify parameters (drive state, command speed, etc.) by acting as a window into the internal functions of a KEB inverter. Combivis has several useful features, including easy-to-use start-up wizards, a built-in oscilloscope, and a document database.

Start-up Wizards

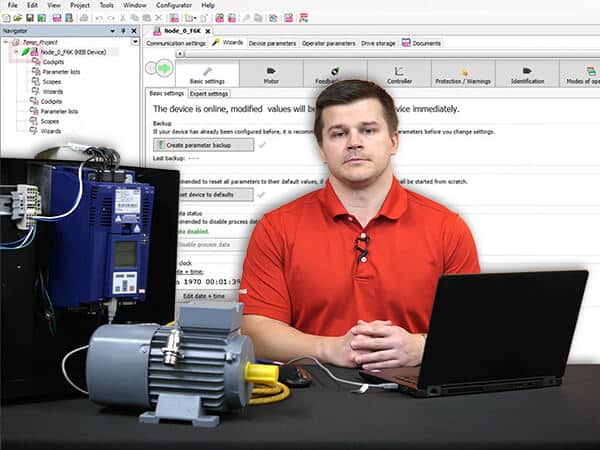

Most software is based on rigid parameter groups designed to be thorough, not intuitive.

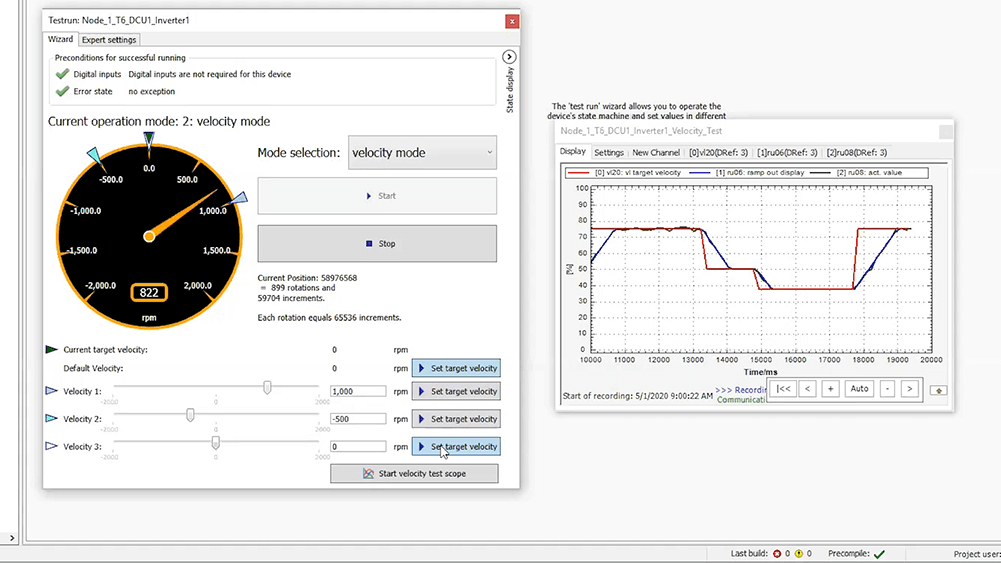

However, the commissioning of inverters is made easy with Combivis’ simple start-up wizards. The wizards provide an intuitive, graphical interface for inputting data and controlling the drive. This transforms the typically technically intensive task of getting an AC motor spinning into something that can be done with minimal inverter programming experience. All that is needed is basic motor nameplate data, and the user can have the motor spinning in minutes.

Combivis 6 Scope Trace Function

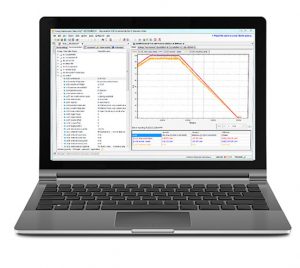

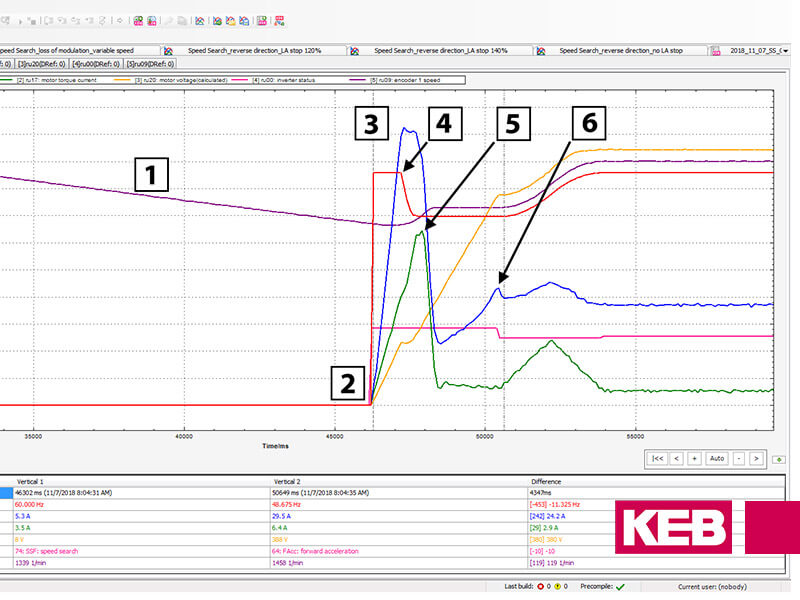

Arguably the most useful troubleshooting feature in Combivis is the built-in oscilloscope. The KEB oscilloscope is a tool that can measure, record, and visualize up to 16 parameters at once. The user needs only drag and drop the relevant parameters (e.g., Motor speed, control/statusword, etc.) into the scope tab. They will be recorded as soon as the scope is initiated. Cursors can also be placed in the scope to measure and compare precise values.

This is extremely valuable for troubleshooting because it allows the user to visualize how parameters change with each other. For example, if the drive were to experience an overload fault, the user could plot the current alongside potential causes to see if there is any correlation.

Additionally, the scope can determine if the drive is registering inputs. The controlword and statusword can be displayed in the scope to see how they change in relation to each other and the controller. All of this can be done without any additional measuring equipment.

Related Article: Glossary of Programming Terms

The scope trace can also determine system demand, such as the current draw. For example, a manufacturer may believe a given motor is needed for an application. However, once the application is set up, the scope trace can be used to determine the actual current demand. The scope might show that only a portion of the rated current is being used. This would allow for design changes to be made for production with a fraction of the original system size.

Other Features

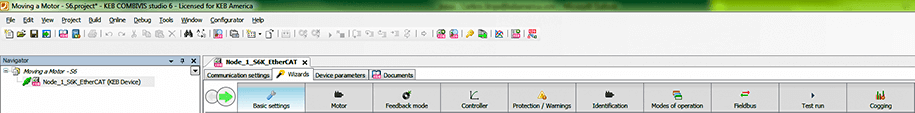

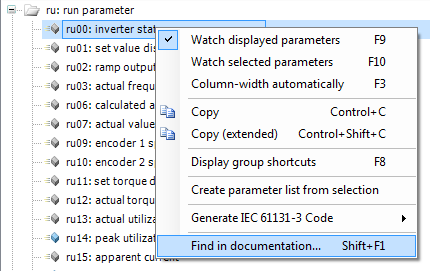

Combivis is easy to learn with an extensive document database built in. If the user runs into a question about programming an inverter (T6, S6, F6, F5, etc.), easy access to the relevant manual is just a click away. Also included in the database is a collection of FAQS for general questions. This is helpful for anyone unfamiliar with KEB inverters.

The test run is a feature that makes it easy to experiment with running the motor. A graphical interface gives the user a simple way to run the motor at the desired speed with minimal setup and without using fieldbus communication.

TeamViewer is also included in Combivis. This feature allows for a simple support experience by allowing KEB remote access to diagnose any programming issues. This is much faster than phone support because KEB can see exactly how the programming is configured.

Conclusion

Combivis makes the programming and commissioning process quick and easy for KEB inverters. The tools included make set-up easy and help the user solve problems at any implementation stage.

If you are interested in seeing how Combivis can benefit your application, please get in touch with a KEB engineer using the form below.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.