Industrial PCs (or IPCs) are crucial tools for industrial manufacturers. They aim to provide a seamless, cost-effective solution for human-machine interface (HMI) and system control. In simpler terms, IPCs empower users by making it easy to run their machines or equipment safely and precisely.

Let’s take a closer look by defining industrial PCs and exploring their utility across different industrial applications.

What is an Industrial PC?

An industrial PC is a computing device that controls processes and collects data for industrial applications. IPCs can be programmed to match exact parameters for safety, speed, throughput, and quality, allowing machines and their operators to execute tasks efficiently.

Industrial PCs include fanless, ventless designs, high configurability, and flexible I/O options. To ensure safety and dependability, IPCs can even be outfitted with waterproof and explosion-proof options for use in hazardous working environments.

IPCs have subsets for specific use cases, such as panel PCs. A panel industrial PC combines a touchscreen display and standard electronics, all within a single enclosure. These panel PCs offer the full functionality of a normal industrial computer, are simple to install, and are designed specifically for use in industrial environments.

What Is the Difference Between a Regular & Industrial PC?

An industrial PC is designed to aid in the production of goods and services by controlling industrial equipment. IPCs can operate 24/7 amidst high temperatures, frequent vibration, dust, and other hostile conditions. This is in sharp contrast to consumer PCs, which run in offices and home desks for 8 hours a day—facing decidedly smaller threats like pet hair and spilled beverages.

Industrial PCs are essential to the success of many manufacturing applications, from process control to data acquisition. They require high precision and dependability, making them more expensive than typical consumer PCs. Fanless industrial PCs leverage a hardshell design and industrial-grade components to make them even more robust and allow for improved uptime.

Benefits of Industrial PCs

Industrial PCs bring a range of important advantages to industrial applications, including the following:

- Longevity: Industrial computers are designed for reliability and uptime, even in isolated environments. Their long life cycles make it easier for businesses to support their application without frequent hardware changes or maintenance trips interrupting productivity.

- Reduced Costs: Industrial PCs reduce the need for machine repairs and inspections, resulting in less downtime and costs overall.

- Superior Results: Industrial PCs offer powerful computing capabilities to improve system throughput and efficiency, enhancing data collection, factory automation, and more.

Applications for Industrial PCs

A fanless industrial PC provides accurate control for manufacturing machines and equipment. The IPC can be used to gather data insights on the performance and status of these machines, enabling predictive maintenance to keep the system running smoothly and reduce any risk of machine failure.

Packaging is another popular use for industrial PCs, where they provide a scalable motion control platform for packaging machines. Industrial computers with HMIs further empower packaging users through built-in data logging, alarm handling, trending, and Secure Remote Access.

IPCs are commonplace in the food and beverage industries, unlocking convenient control and access to machine data. Food or beverage processing plants are harsh and demanding environments, making a panel industrial PC a natural fit. For example, KEB’s IP69K HMI stainless steel panel is moisture- and water-resistant—allowing users to safely wash down the equipment with high-pressure water or steam.

Other growing applications for industrial computers include asset tracking, particularly in the medical and healthcare sector, and remote data collection via IoT sensors and other connected devices.

KEB Industrial PC Solutions

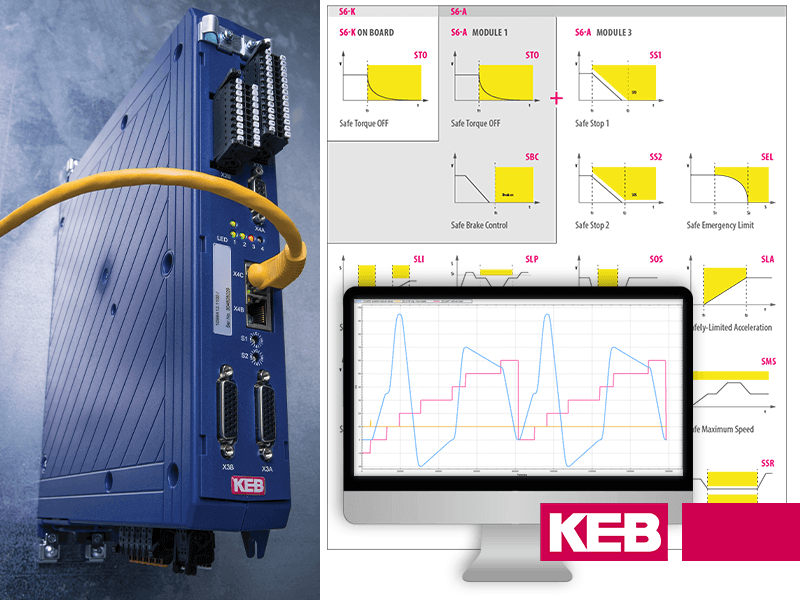

KEB’s C6 Industrial PC series delivers next-gen computing power focused on human-machine interface and motion control. The C6 is an embedded IPC, providing multi-axis coordinated motion control and camming. Features include an EtherCAT master, an integrated EtherCAT bus coupler, and capacitive or resistive touch options. The C6 IPC can also be paired with KEB HMI solutions for enhanced display and PAC functionality.

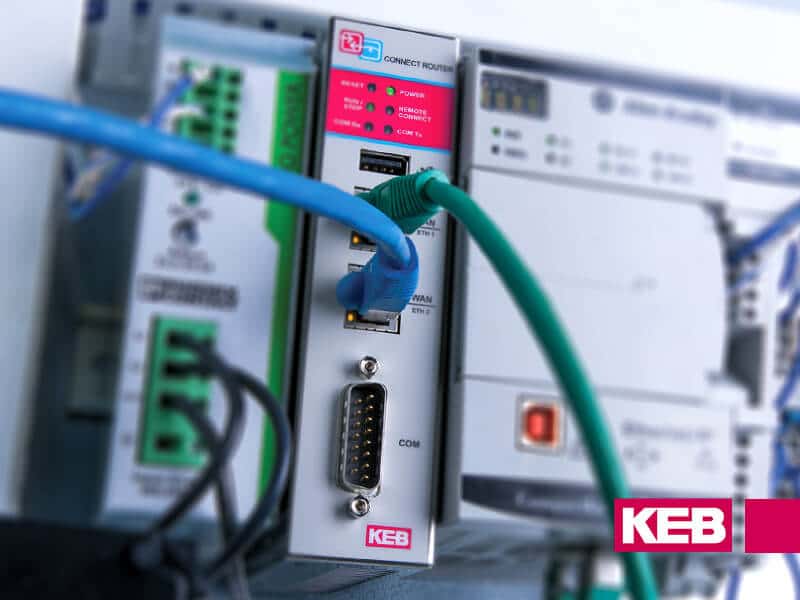

KEB offers a complete PLC + HMI combo through our C6 S14 IPC. This is a comprehensive machine controller with Micro UPS backup and access to KEB’s CONNECT secure remote access platform. Ideal for medium- to high-performance machines, the S14 IPC is a powerful, flexible solution to meet your application’s PLC and human-machine interface requirements.

Explore the Future of IPC Technologies

Need to commission an IPC or other automation tool for your industrial application? KEB is an industry leader in control and automation technologies, tailor-fit for your unique needs. Connect with our team today to learn more about our diverse IPC solutions—and take the performance of your application to the next level.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.