If you’ve been reading our blog then you know that KEB is a leader in drive technology for Plastic machines. One application that KEB has a lot of experience in (20+ years & 100,000+ units installed) is operating hydraulic pump motors on injection molding machines. The post gives an overview of the application and some of the advantages KEB brings to the table in hydraulic pump control.

Operating the hydraulic motor from the mains

Historically, injection molding pump motors were connected to the mains power and operated at a fixed speed with a simple on/off control. With the motor running at a constant speed, the fluid volume and pressure were regulated through hydraulic valves. While this control method is very straightforward and easy to implement, throttling with valves can be extremely inefficient and can create excessive heating in the system.

Studies have shown that an injection molding machines hydraulic drives can account for nearly 50% of the machine’s energy usage – So improving the energy usage of the pump goes a long way in improving the overall machine efficiency.

Quick Start Wizard for Servo Pump Applications

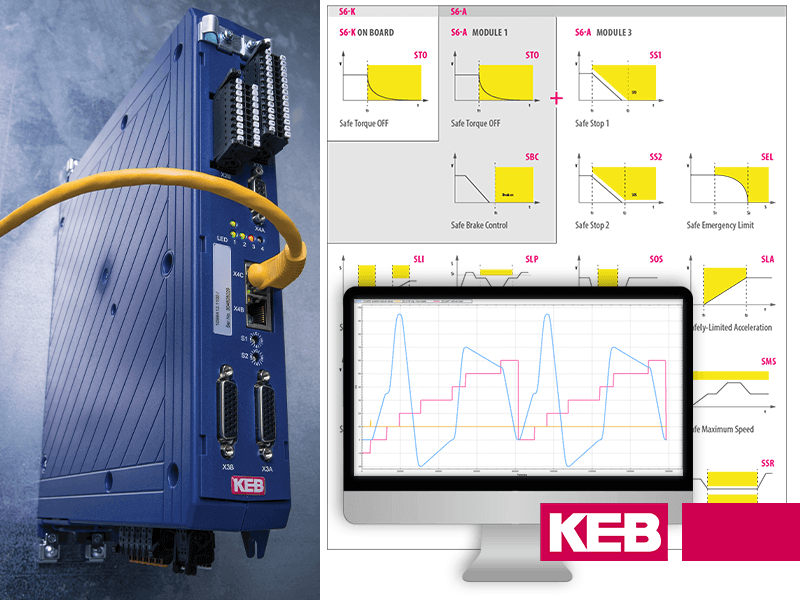

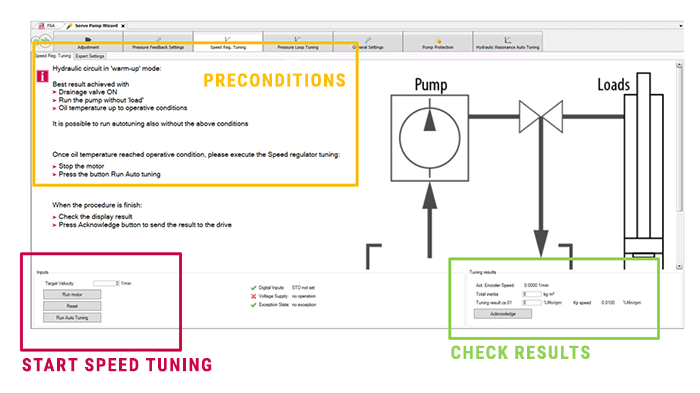

Wizards inside the COMBIVIS 6 software are designed to help programmers understand and adjust the many functions in KEB’s F6 and S6 VFDs. Unlike strict parameter, text-based drive programming, wizards are extremely valuable to get up and running quickly. The servo pump wizard, as seen below, is designed to offer essential functions in an easy to navigate interface so you can establish hydraulic pump control in a short time. You can enter pressure feedback settings and other information, as well as conduct a speed regulator tuning. The image below highlights the preconditions section offering tips for a successful tuning, the speed tuning test buttons for auto tuning and running the motor, and then you can check your results on the bottom right in the tuning results section.

KEB’s Solution – ASCL Pump Control

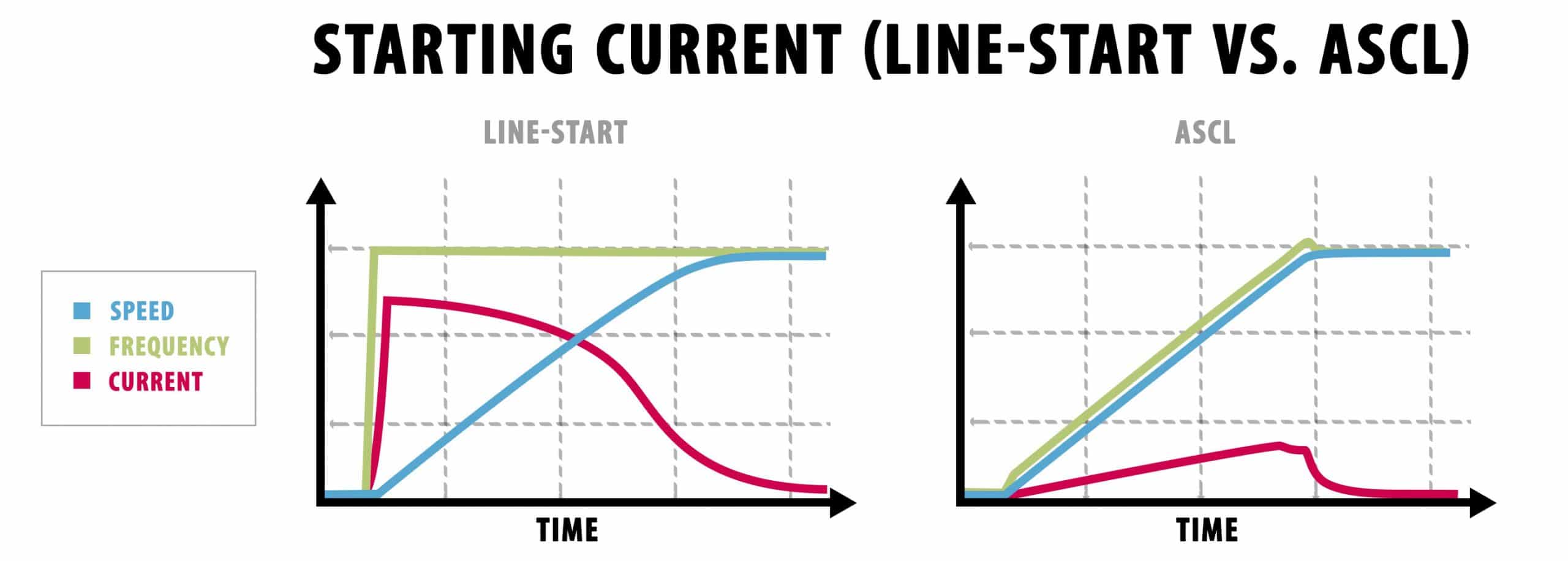

It has been well documented that a pump’s speed and flow can be regulated by adding a VFD to the pump’s induction motor and controlling the motor speed with simple V/Hz control. V/Hz control has the added benefit that it soft-starts the motor. This is a big improvement over line-starting which causes large inrush currents and excessive mechanical wear.

However, basic V/Hz control has some performance limitations – for example, it does not make any adjustments for the induction motor’s slip because there is no feedback mechanism. Additionally, V/Hz control will have torque limitations at low speeds.

KEB’s ASCL motor control is the answer. ASCL uses an advanced motor model and continuously measures the VFD’s output current and motor back EMF to precisely calculate the motor speed. The drive is able to make small current adjustments on the microsecond level to provide the optimal operating point, even at reduced speeds.

Retrofit Opportunities

Because ASCL does not require any feedback and can be used with any manufacturer of induction motor, it can be easily added to existing installations.

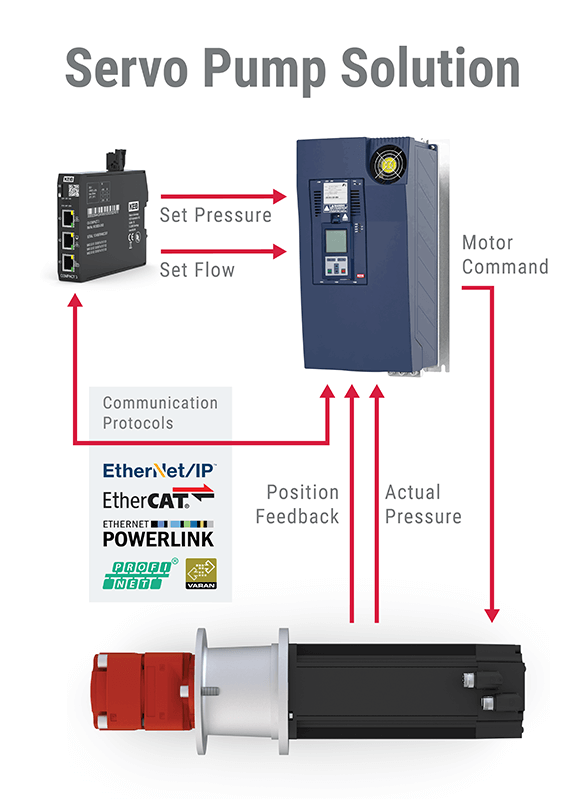

Servo Pump Control

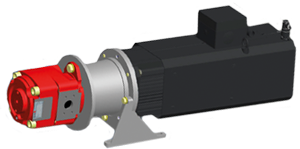

For even more responsive control, a servo motor can be used instead of an induction motor. A PM servo motor will provide increased power density, responsiveness, and efficiency compared to an induction motor. KEB’s SCL software functions much like ASCL except it is intended to be used with a Synchronous PM motor.

Again, the software does not require a feedback device and expensive encoder cabling but still provides exceptionally accurate speed regulation across a wide range. All of KEB’s drive platforms support ASCL/SCL software.

Internal PID Control

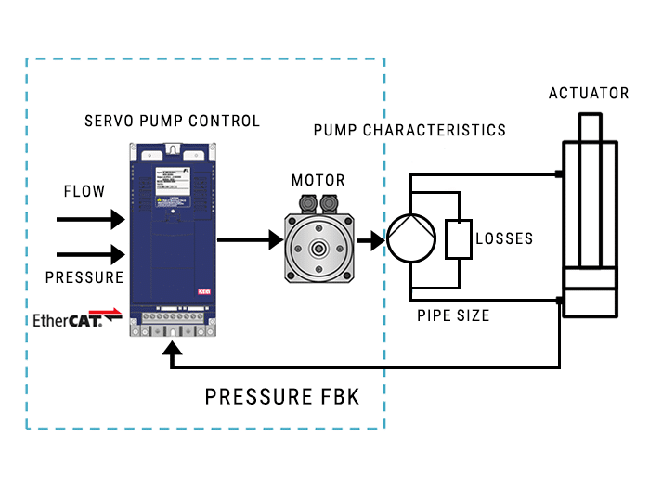

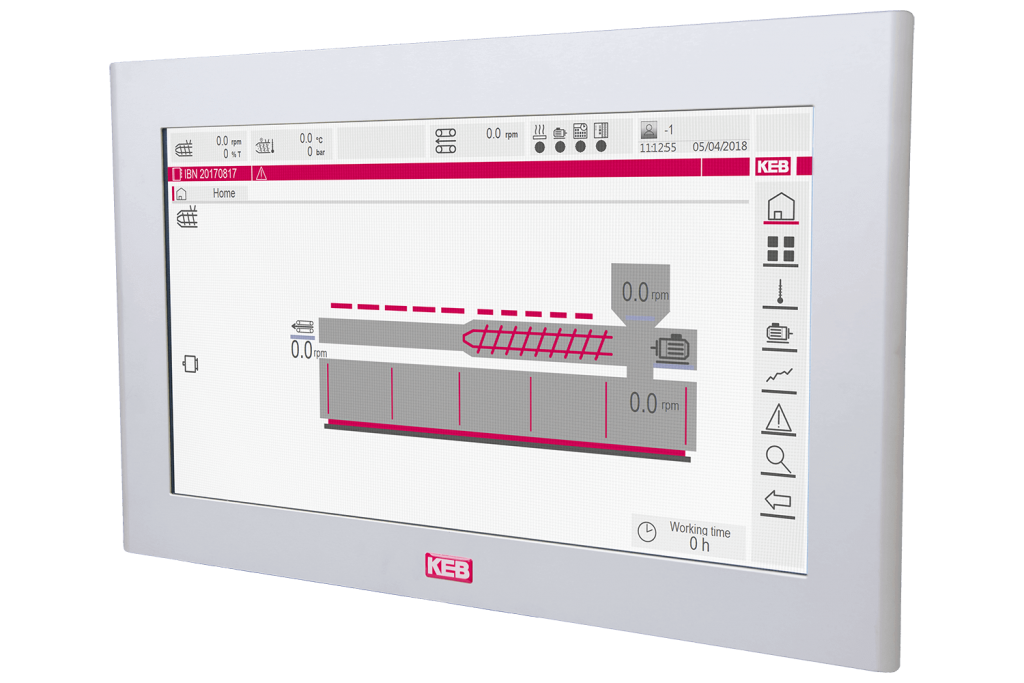

There are many ways hydraulic pump control can be handled. Historically, the PID control was handled in the PLC or a dedicated pump controller and the VFD was simply given a speed command. But another implementation is to let the VFD manage the PID control for the hydraulic drive. In this arrangement, a PLC or machine controller would provide the drive with an analog input for the desired pressure setpoint. A 2nd analog signal which measures the actual pressure is used as feedback in the control and is also fed to the drive.

KEB’s S6 and F6 drives, for example, are perfect for this implementation as they have an internal PID function reserved for controlling an auxiliary process. This configuration simplifies a system by offloading some processing from the PLC and does not require a special dedicated pump controller.

Other KEB Drive Features

In addition to ASCL/SCL motor control and an internal PID function, KEB drives are ideal for injection molding hydraulic pump applications because they offer SIL3 rated safety functionality like Safe-Torque-Off. Additionally, high speed Ethernet bus options like EtherCAT can be used which boast 500µs scan times and can be easily integrated with the machine controller.

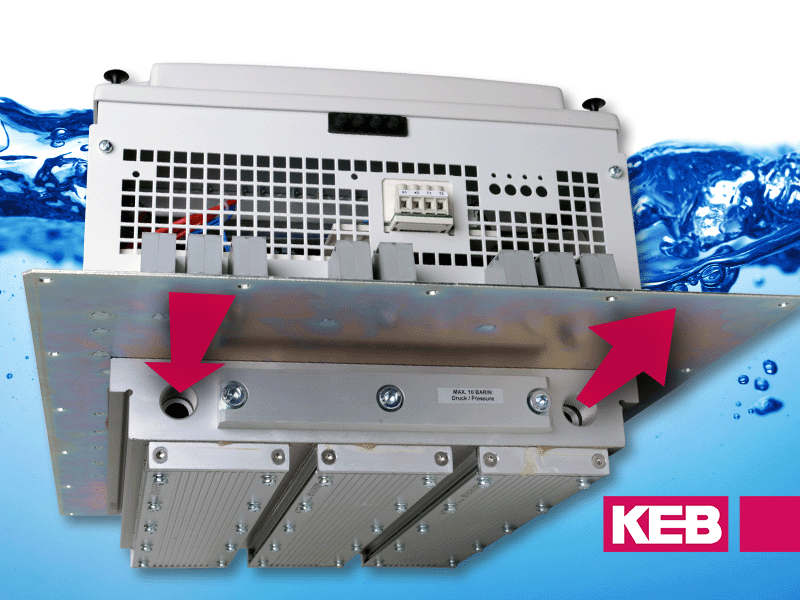

In addition to the standard fan cooled design, liquid cooled heatsinks are available which allow the drives to output more power for a given frame size.

In summary, here are the features and benefits with using a KEB drive on your hydraulic pump:

| Feature | Benefit |

|---|---|

| ASCL/SCL – Precise speed control without feedback |

|

| Less heating in the system |

|

|

Internal PID controller |

|

| Less audible noise |

|

| Potential for field weakening operation |

|

| Standard KEB hardware/software |

|

Better Machines with Better Drive Technology

KEB’s success running hydraulic pumps is not limited to injection molding machines. Similar hydraulic applications for balers, rams, presses, shears, and lifts all could benefit to adding a VFD.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.