Direct drive motors are a unique type of synchronous motor for high-speed applications. Machine builders can leverage direct drive motors to improve power and speed control while significantly reducing the number of moving parts within the system. This approach reduces complexity, lowers maintenance costs, and provides greater flexibility without sacrificing performance.

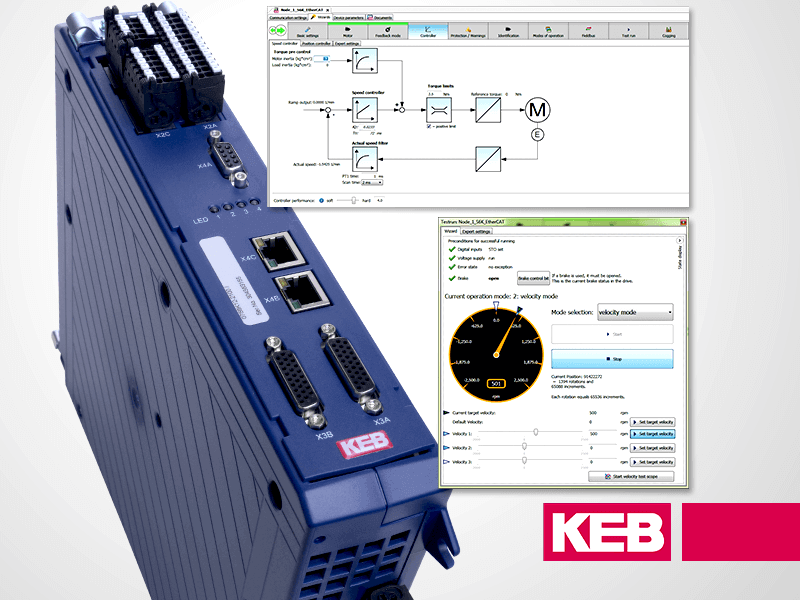

KEB provides leading control and automation solutions for customers worldwide, including VFDs for direct drive high torque servo motors. Today we’ll cover the basics of direct drive motors to help you understand how they work and whether they’re the right fit for your application needs.

What Are Direct Drive Motors?

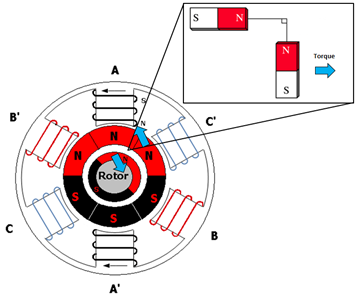

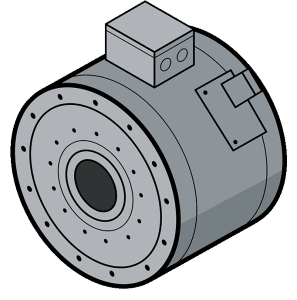

Direct drive motors refer to any linear or rotary motor that directly drives a load. These motors eliminate mechanical transmission components (like gearboxes and belts) to simplify the system, improve efficiency, and maximize lifetime. Direct drive motors provide exceptional speed control and power for their size and weight and are suitable for a wide range of applications, from elevators to industrial shredders.

Machine builders use direct drive motors to support more dynamic and quiet operations. These motors don’t rely on gears, belts, couplings, and chains like traditional geared motors. As a result, they’re much quieter and easier to maintain. Efficiency is the name of the game for direct drive motors; they deliver remarkable power density, unlocking new levels of performance across the system and beyond.

Types of Direct Drive Motors

There are multiple types of direct drive motors, from torque and linear motors to frameless motors. Here’s an overview of some popular direct drive variants for use in industrial applications:

Torque motors are unique because they don’t require intermediate gearing or belting to slow their output speed. These specialized electric motors can still operate when stalled without damaging or negatively impacting the system. Common applications include throttle control and actuators in servomechanisms or motion control systems.

Linear motors create a linear force to move a load. Linear motors provide an exceptional combination of precision and power, making them a popular choice for material transport and industrial automation equipment. Their performance can be further improved when controlled by a specialized VFD for linear motor applications.

Frameless direct drive motors take this concept one step further, removing the motor housing entirely. This allows the motor to be directly integrated into the application without additional interfacing requirements. This frameless design removes mechanical elements between the load and motor, improving dynamic performance in the process.

What Are the Advantages of Using a Direct Drive Motor?

Direct drive motors bring many benefits to industrial applications, including the following:

Dependability: By removing the need for mechanical transmissions, direct drive motors have fewer components that wear, fail, and require replacement. This reliability makes direct drive motors especially suited for applications demanding 24/7 uptime or long service intervals.

Some applications like industrial shredders stress gear components with high shock loading. Using a direct drive motor removes this component that is prone to failure over time.

Cost Efficiency: Direct drive motors use fewer parts vs. traditional motors by eliminating gears, belts, and couplings. This design approach lowers the cost of assembly, reduces maintenance, and boosts power density. Direct drive motors generate substantial power in a compact package, freeing up space in the system and supporting more space-efficient solutions.

Speed & Precision: Direct drive motors enable higher acceleration to increase system throughput without compromising accuracy or quality. These motors increase repeatability by removing belt compliance and gearbox backlash from the equation altogether, which is a massive perk for high-precision operations.

Direct Drive Motors for Industrial Applications

Direct drive motors support a variety of industrial applications, particularly those requiring fast speeds and acceleration in a compact space. For example, packaging applications can use linear direct drive motors to great effect in their machinery, moving goods quickly and safely across the packaging line.

Direct drive high torque servo motors are also used in elevator applications. These motors work in tandem with Line Regen drives and other technologies to reduce energy consumption, increase system safety, and surpass elevator code requirements. Other common applications for direct drive motors include machine tools, manufacturing equipment, and even robotics systems.

KEB: Your Partner in Control & Automation

Want to learn more about direct drive motors and how to leverage them for your application? At KEB, our team has over 50 years of experience delivering powerful and versatile control solutions for customers. Contact a KEB solutions engineer today to find the right motor for your unique needs.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.