Over the past decade, one substantial change in automation has been the legislation to design and sell energy-efficient motors. Motor manufacturers have to comply with new efficiency requirements. First, there was IE2, then IE3, and stricter IE4 motor efficiency requirements are around the corner.

These new efficiency requirements have increased the upfront costs of motors. However, users should always consider the total lifetime operating expenses, including the electricity cost. Online tools can help a user approximate energy savings over time. Furthermore, users should know that many local utilities offer rebates for using energy-efficient motors and VFDs. These rebates are often “free” to apply for, and worth investigating if they are available for your project.

The Drive to Use Energy-Efficient Motors

Motor manufacturers have increased motor efficiency by increasing the amount of material (copper in windings) in the motor and using more efficient technologies (e.g., permanent magnets). These changes to the motor construction have increased the upfront motor cost. Of course, users should always consider that much of the lifetime costs in an industrial motor come from the ongoing electrical energy costs, not the motor itself.

The cost savings calculation due to improvements in motor efficiency is straightforward. The calculation requires the energy usage of the different motors, which is a function of the motor duty and usage over its lifetime. The calculation will also use the expected electrical energy costs over its lifetime. Higher duty, higher power applications with high electricity costs will provide the most savings.

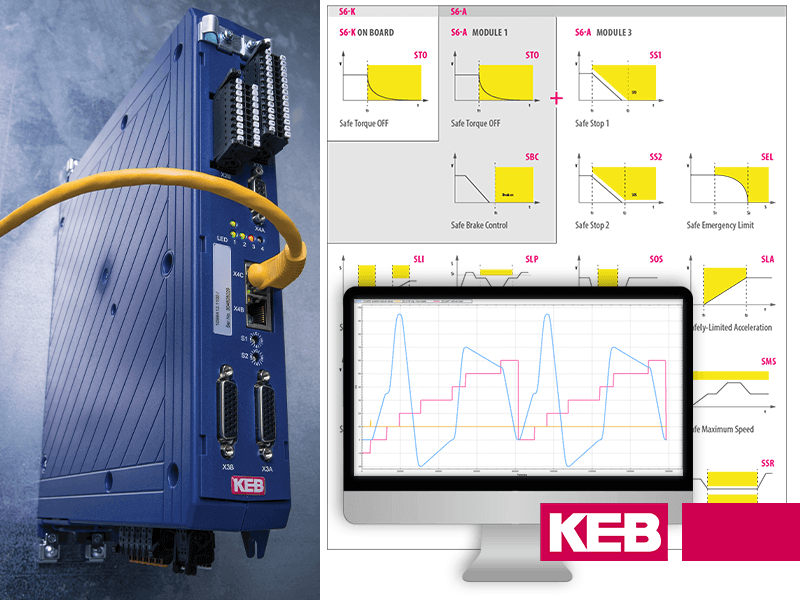

VFD-controlled Motors

In addition to legislating the use of energy-efficiency motors, governments are pushing for pairing motors with VFDs and other energy-saving technology. Using VFDs is especially important for continuous applications like pumps and fans where the motor is often “turned down” to a lower speed. Alternatively, when a motor is fed directly off the line, the reduced output is achieved with throttling valves and dampers which are very inefficient.

VFDs allow motor speeds to be varied depending on demand. However, like efficient motors, adding a VFD to the system increases the upfront costs to users while promising a lower lifetime cost through the reduction in energy usage.

Regenerative Drives

When using a VFD in cyclic applications like centrifuges, hoists, and elevators, the mechanical system’s energy is returned to the VFD. Traditionally, this regenerated energy was bled off through a braking resistor and wasted as heat. In this case, an energy-saving technology that could be utilized is KEB’s regenerative drive. Regenerative drives allow that energy to be returned to the building power, where other electrical loads consume it. The net result is lower energy consumption.

Related Article: Elevator Regen Calculator

Many application-specific online tools approximate energy savings when using a VFD or related technology. KEB offers such a calculator when using Regenerative drives for Elevator applications. The calculator allows a user to input some basic system and usage parameters of the elevator and outputs the energy savings in kW and dollars. Tools like this are invaluable for understanding the payback period for these investments.

Rebates to Promote the Adoption of Energy Efficient Technology

Governments understand there might be pushback to investing in these new technologies and are incentivizing users to adopt these technologies through utility rebates. There are Federal, State, and Utility-funded rebates in the United States.

The DSIRE USA website allows users to search for open rebate programs by state. The number of rebates available does vary widely depending on the state initiatives and funding. A glance at the state KEB America operates in, Minnesota, shows there are 136 programs openly running:

A Typical Utility Rebate

The DSIRE website allows users to quickly filter out basic criteria to see if they qualify for rebates. For example, here is a rebate offered by the Anoka Municipal Utility across town. It applies to installing and using both Energy Efficient motors and VFDs.

Conclusion

With rising energy costs, users of industrial machinery should be increasingly focused on the lifetime operating costs of the machine. Using efficient motors and VFDs promises to lower operating costs, but the exact amount depends heavily on the type of machine, duty, and cost of electricity.

Furthermore, users should be aware that using efficient motors and VFDs often allows them for rebates through their local utility. At a minimum, users should check the DSIRE website or reach out to their local utility for more information.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.