KEB and the Future of High-power, High-speed Elevators

With higher elevator speeds inherently comes higher power in terms of both the energy put into elevator systems (elevator drives) as well as the potential energy returned (regen drives). As the number of high-rises and super-tall buildings applications increase and higher speeds become more frequent and push new bounds, there will be the need for OEMs to supply equipment in these corresponding high power ranges that serve the elevator market.

High Power Elevator Drives

As an industrial drives manufacturer, KEB is not only active in the elevator market but also supplies inverters for applications such as plastics machinery (extruders, etc.), high-speed compressors and blowers, and shredders. All of these applications typically require drives with high power ranging from 200kW to 800kW. But, simply having a power hardware overlap with other industries does not necessarily make for a solution that is suitable for elevator applications since the requirements are different.

Often, other high-power drive applications do not require high peak currents as they are constant run applications and low, but audible, output switching frequencies (e.g. 2 kHz) is suitable when equipment is installed in a remote or industrial environment. Additionally, the low switching frequencies minimize the heat dissipation and thus the physical size of the drive and its enclosure.

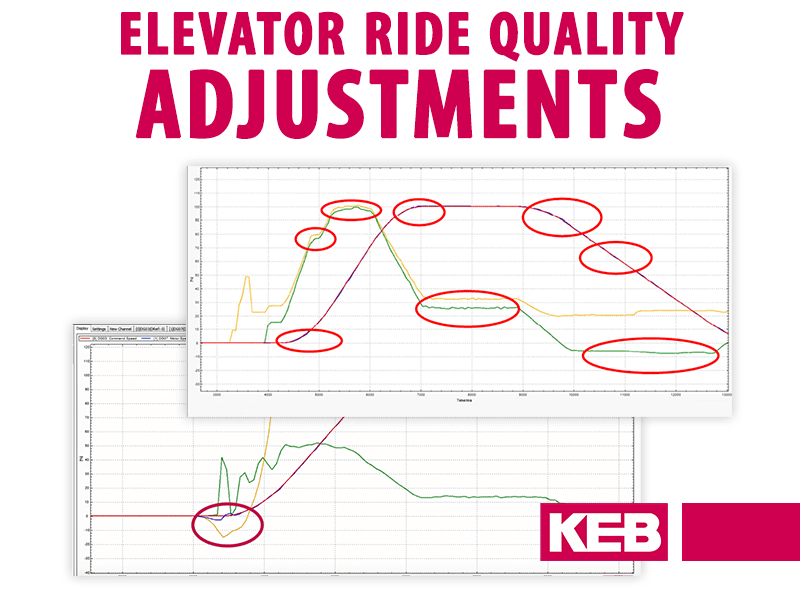

Whereas, the drives needed for elevator applications require high peak current in comparison to the nominal rated motor current and a switching frequency nearing the audible spectrum limit (e.g. 8 – 10 kHz is generally acceptable). The comparatively high peak current requirements of elevator applications are based on typical acceleration and deceleration rates. Currently, overload requirements are pushed even higher when specified floor-to-floor times require more aggressive speed profiles.

Requirements that Drive Large Elevator Drives

What differentiates high rise and high-speed elevator applications in terms of higher nominal and peak power demand can be exemplified by the equations for kinetic energy, power, and torque.

The equation for linear kinetic energy equation is KELINEAR = ½ mv2 where m = mass and v = velocity. This indicates that there is a linear relationship between mass and the energy required to accelerate it. Beyond a given load capacity of an elevator, there is also additional mass from ropes, traveling cables, etc, which is proportional to rise.

Therefore, independent of elevator load capacity, as rise increases the system mass will increase, and thus the required energy and power increases. In terms of high speeds, if this is achieved by increasing the motor speed, then the equation Power ≈ (Torque x RPM) / 5,252 indicates that for a given sheave diameter based on speed and a given torque requirement based on load, as the motor speed increases the required motor power will also increase.

On the other hand, if high speeds are achieved by increasing the sheave diameter, then the equation Torque = Force x Radius indicates that the required power from the higher required torque will also increase.

While a drive could simply be oversized to meet the peak motor requirements, a better solution would be a nominal drive rating that is in line with the motor rating to minimize the physical size and cost but also have a high peak current based on the requirements of the application.

From the existing variety of high power hardware developed from other industrial applications and taking into consideration the needs of the elevator market, KEB has recently added to its portfolio of elevator drives a design solution that meets the high power demands of high speed and high-rise elevator applications. The resulting solution is an F5 model elevator drive rated for 250HP with a rated current of 332A (480V mains voltage supply) or 370A (400V), a 30-second peak current rating of 740A, and up to an 8 kHz output switching frequency. Furthermore, design variants are cost-optimized by eliminating redundant input rectifiers and braking transistors when line regeneration or active front end (AFE) units are supplying the drive via a DC bus connection.

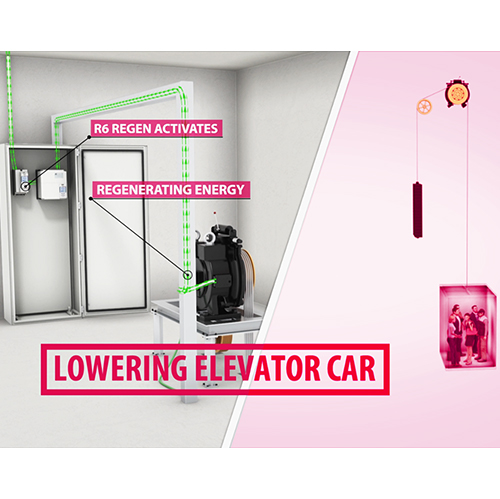

High Power Line Regen Systems

With high power being put into the system, there will be a correspondingly high power regenerated in overhauling conditions. Given that high-rise applications will almost definitely be gearless, the system is very efficient in terms of capturing regenerated energy and prime candidate as a line regen system to regenerate this energy back to the mainline to be consumed by other loads and thus reducing the total system operating costs.

When considering line regeneration for elevator applications, there are three options: 1.) line regeneration unit with commutation choke (<50% THDi), 2.) line regeneration unit with passive harmonic filter (<8% THDi), or 3.) an active front-end system (<5% THDi). Each has increased performance in terms of harmonic current distortion mitigation and power factor correction, but also at increasing price points. The type of system needed may depend on the need to meet specific IEEE-519 harmonic distortion limits, reduce building power consumption as part of a building green certification initiative, or long-term return on investment considerations.

Similar to inverter applications, KEB has already developed high-power regen solutions relevant to elevator applications based on other global applications such as crane applications and storage and retrieval systems. The corresponding high-power solutions for each type of line regen technology include: modular R6 model line regen sizes including 150 HP units rated for 184A at 480V or 221A at 400V and 331A peak, which can also be also paralleled for additive capacity; harmonic filters up to 400 HP rated for 400A at 480V and include designs in dedicated NEMA enclosures; and H6 model active front end units up to 250HP.

Systems in Application

KEB recently had the opportunity to put one of these high-power solutions to the test on an 8 m/s (nearly 1,600 FPM) elevator. The system components provided by KEB consisted of a 250HP F5 Elevator Drive, a 250HP H6 Active Front End, and an EMC high-frequency noise filter. Additionally, we were given the opportunity to visit the job site. Although I had personally not worked with such high power equipment in the past, when it came to starting up and adjusting the elevator, it was the same user interface, parameters, and control performance I am familiar with in North America…just on a much higher-power and faster scale!

KEB – Your Drive Partner for Elevator Applications

Contact a KEB Elevator Drive engineer to discuss your next application or fill out the form below.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.