KEB Drive Motor Learn Procedure with Combivis 6 Software

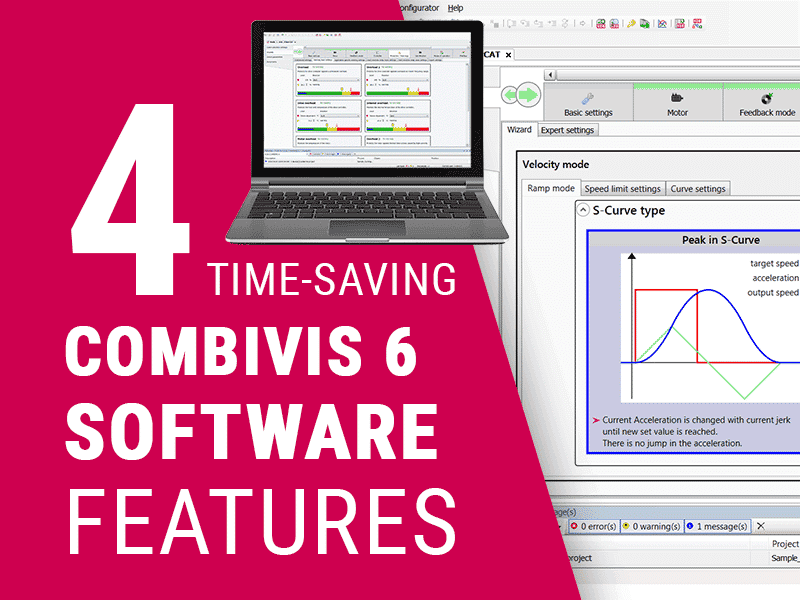

Commissioning an inverter for an AC motor application shouldn’t be a daunting task. If the user has to start by wasting time hunting through pages of documentation to get the motor spinning, this can lead to lost development time that is better spent elsewhere.

KEB’s motor learn is a tool that saves valuable development time by “learning” those hard-to-find motor characteristics on its own, just from the basic nameplate data. This transforms the technical task of getting an AC motor to spin into a simple task that can be done even with minimal inverter programming experience.

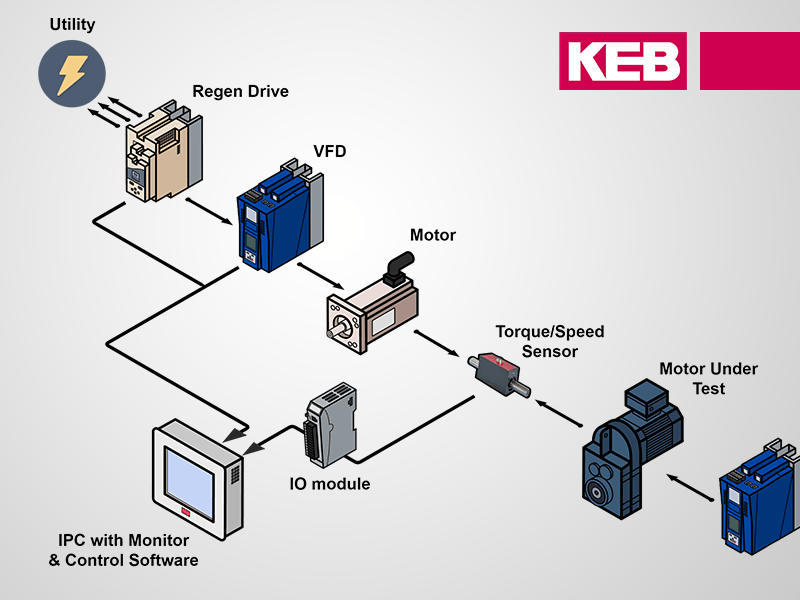

In Combivis 6, KEB’s free inverter programming software, the steps are laid out sequentially to offer a foolproof start-up experience. Watch the video below for a step-by-step video tutorial on the full motor learn process. Note: this example uses a T6 Auxiliary Inverter, however, the same process is used for S6, F6, and other KEB VFDs.

Steps to Complete the Motor Learn Process

Motor Data Input

Combivis 6 requires very little information from the user, even if the user plans to implement advanced control strategies. Everything needed for advanced operation can be gathered from the motor nameplate.

For asynchronous motors, this includes:

- Rated Current

- Rated Voltage

- Rated Speed

- Rated Frequency

- Rated Power

- Rated cos(φ)

For synchronous motors, this includes:

- Rated Current

- Rated Voltage

- Rated Speed

- Rated Frequency

- Rated Torque

This data gives the KEB inverter the baseline knowledge it needs to understand what type of motor it is dealing with.

Feedback Mode

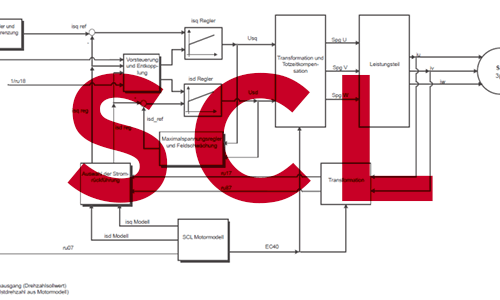

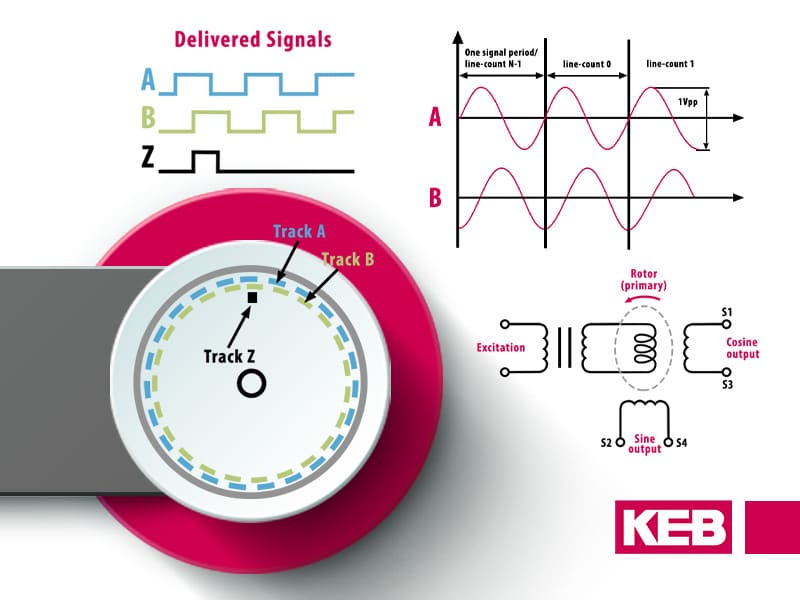

The next step is to choose the type of feedback the motor will operate with. Depending on the inverter, the user can typically choose between V/Hz, encoder, or sensorless-closed-loop (ASCL/SCL) operation.

Controller

Next, the speed or position controller can be adjusted. The most important part of this step is setting the motor’s inertia. An exact value is not required since the user can later perform a calculation to determine the motor inertia. If the inertia is unknown, an estimated value is usually satisfactory.

Motor Identification

With the previous steps completed, the inverter is ready to begin the motor identification. The motor identification wizard walks the user through the necessary preparations, including setting the brake control and enabling the voltage. The motor identification can then begin.

the motor must be set up so the motor can rotate without load because the motor will spin during identification.

Once the identification begins, the user will notice the motor making whirring sounds. These sounds are the inverter performing operations to learn the motor characteristics it previously did not know, such as stator inductance and rotor resistance. Toward the end of the motor learn, the motor will spin.

The wizard will let the user know once the identification has been completed. From there, the inverter has learned everything it needs to know to operate efficiently in whatever feedback mode the user selected.

Conclusion

A quick commissioning process is valuable during development. Avoiding the hassle of chasing down complex motor characteristics will save you time and put you ahead of schedule.

If you are interested in seeing how KEB’s software and other products can benefit your application, please contact a KEB engineer using the form below.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.