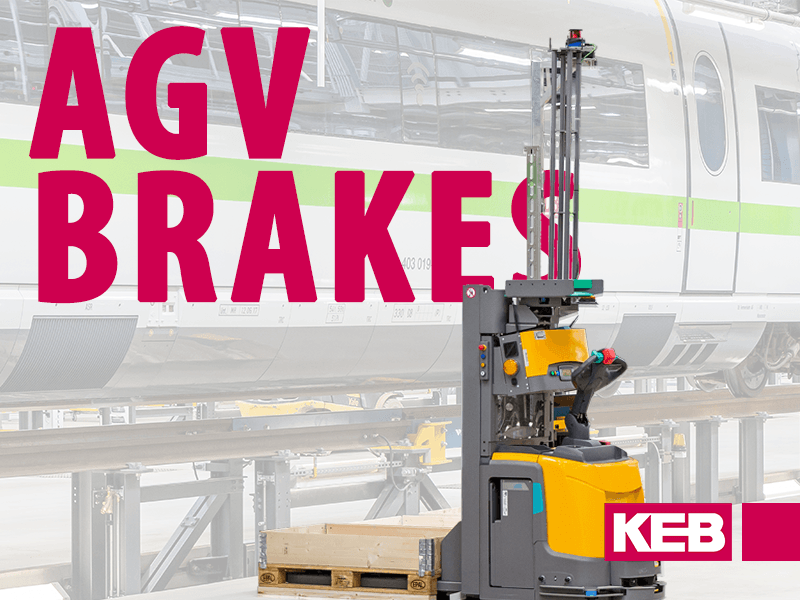

Current draw and power consumption can be very critical in some brake applications. This is especially true for battery-powered applications for AGVs, mobile carts, forklifts, and robotics. Reducing the brake current draw means the battery will last longer before needing to be recharged.

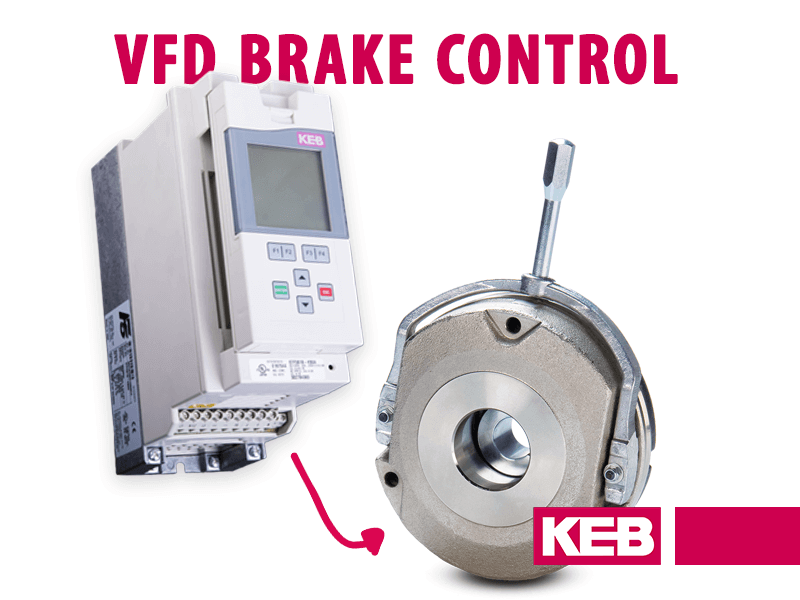

In this article, I will be highlighting the advantages of using KEB’s 24VDC Powerbox for 12 and 24VDC Spring Applied Brakes and Permanent Magnet Brakes, which are both power-off brakes.

Power-Off Brakes & Holding Voltage

As their name implies, Power-off brakes do not draw current when the brake is engaged. When the rated voltage is applied to the brake, the brake opens and the motor shaft is free to rotate. Once the brake is open, the required voltage to keep the brake open is reduced. This is often referred to as the “holding voltage.”

This holding voltage is application dependent and depends on a number of variables including the brake’s air gap. For KEB’s Spring Applied Brakes, our recommended holding voltage is 50% of the nominal voltage for a nominal air gap. The power consumption in the brake coil is reduced along with the reduced holding voltage.

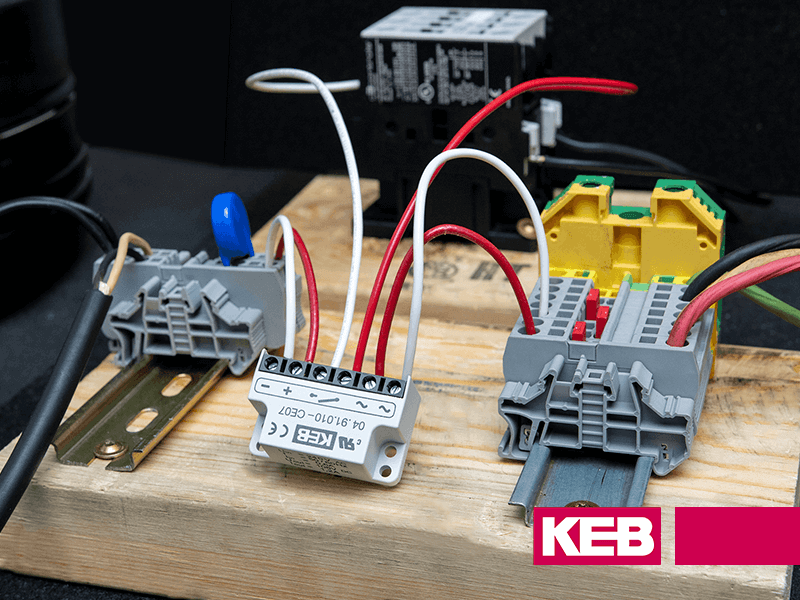

KEB 24V Powerbox

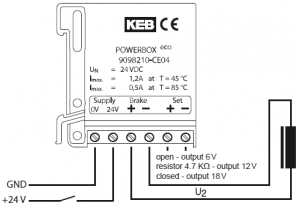

KEB’s 24V Powerbox is an excellent way to provide a reduced holding voltage to DC Brakes. Looking at the schematic below you can see that with the addition of a resistor, the output voltage can be adjusted to be 6, 12, or 18VDC and this is done by Pulse Width Modulation (PWM) within the Powerbox.

When the Powerbox is supplied with 24VDC it will output 24VDC at 7Amps (3.5Amps at 75°C) for a duration of 800ms. This is enough voltage to either dis-engage a 24VDC brake, or over-excite (dis-engage quicker) a 12VDC spring-applied brake. It will then lower the voltage to 6, 12, or 18V depending on your wiring diagram.

For a 12VDC brake, you would want to have no connection (outputs 6VDC) and for a 24VDC brake, you can decide between the three depending on the application, air gap, and brake technology. The Powerbox will work properly in a temperature range of -40°C to 75°C but do note the change in allowable amperage.

Advantages

- Reduction of power consumption — Longer battery life

- Reduced heating

- DIN rail or bolt-on mounting

- Small size of 18 x 59.5 x 57.5 (W x H x D, mm)

- Quicker engagement of 12VDC spring applied brakes

- Quick return on investment due to energy savings

Applications

- Battery-powered machines (automated guided vehicles, forklifts, robotic arm brakes, etc.)

- Brakes that are continually supplied power (due to energy/cost savings)

- Temperature-sensitive environments (cold or hot)

- Applications requiring CE rating

- Industrial Trucks, Cranes, Medical, etc.

Example – Automated Guided Vehicle (AGV)

Brake nominal specs: 24VDC, 130W, Current draw of 5.42A at nominal voltage

Powerbox wiring: 4.7 kΩ resistor (12V output)

Brake consumption with Powerbox: 12VDC, 32.52W, 2.71A

Savings: 2.71A draw from the battery

- This will almost double the life of the battery from a brake perspective

System Example

*Same brake as the example above

Number of brakes per system: 25

Hours of operation: 24 hours

Days of operation: 6 days a week for 52 weeks (312 Days)

Brake power per year: 973 KWh

Brake power with Powerbox per year: 244 KWh

Power savings per year of 729 KWh

Current KWh price in Minnesota (as of 4/19/2022): $0.115

Savings per year per brake: $83.84

Total savings per year per system: $2,095.88

*in a more expensive state, such as Massachusetts ($0.196 per KWh), your savings would be:

$142.88 per year for each brake, or

$3,572.10 per year for a 25 brake installation

Powerbox – A better brake control

Do you think a Powerbox might be a good solution for your application – contact a KEB America engineer today.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.