Spindle motor control uses a combination of spindle motors and drives to power industrial machinery. This control technology is favored for many applications, from CNC automation and woodworking to robotics, because it offers tremendous flexibility and value for its cost.

KEB has over 500,000 installed spindle drives worldwide, empowering customers with more versatile, purpose-built drive platforms. For example, our S6 servo drive delivers unmatched performance to improve the quality and consistency of CNC machine processes.

Let’s explore the basics of CNC spindle solutions—and how a drive platform like the S6 can help you produce the best final product for customers.

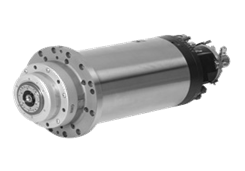

What Is a CNC Spindle Motor?

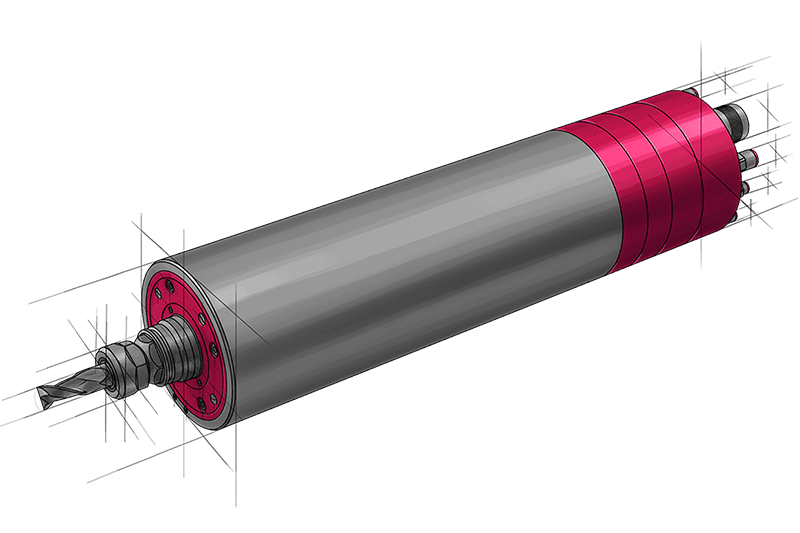

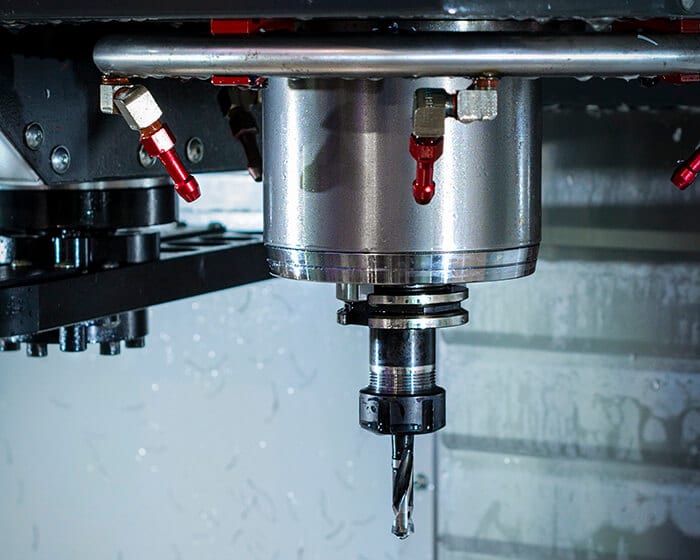

A CNC spindle motor is a reliable, high-speed motor specifically built for use in computer numerical controlled machines. Like many motors, it converts electrical current into mechanical energy to create precise motion. More specifically, a CNC spindle motor rotates the spindle unit, which holds the tools for machining components. Spindle motors offer stable speeds, large torque, and long lifespans, making them ideal for the growing demands of the CNC industry.

Spindle motors for CNC require a unique type of drive to regulate and control power fed into them. These are called spindle drives, which enable accurate control of machine acceleration, speed, and torque. Together, spindle motors and drives equip CNC machines to make extremely precise cuts and manipulate workpieces to exact standards.

Are Spindle Motors Induction Motors?

Spindle motors are essentially a more specialized type of induction motor. They use the same principles and workings to create motion; however, spindle motors are uniquely built to rotate a spindle unit. Spindle motors for CNC also leverage special sensors to monitor temperature and velocity in machines, which helps control risk and reduce system downtime.

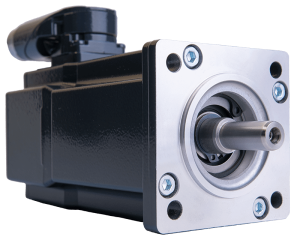

Servo Motors vs. Spindle Motors

Spindle motors differ greatly from servo motors, both in how they’re configured and their ideal use cases. No single motor type is “better” or superior to others; the key is choosing the technology best suited to your needs. That said, let’s dive into the general differences between servo motors vs. spindle motors:

Servo Motors excel at giving precise positioning control, relying on a feedback element like an encoder in a closed-loop system. These machines are versatile because they are not limited to generating rotating motion. This allows them to be integrated with various machines and applications, from printers and milling machines to robotics.

Spindle Motors are velocity-controlled and are well-suited for creating rotating movement. They rely on an open-loop system and magnets to function without an encoder or resolver. While less flexible than servos, spindle motors for CNC are supremely power efficient and lightweight. They also produce low noise, vibration, and material consumption. These advantages make them ideal for metalworking machines and wood, stone, glass, and PVC.

Despite these general differences, both motor types can be augmented with various technologies to suit your needs for CNC. For example, spindle motors can be enhanced with controller feedback for more accurate positioning, allowing measured shifts in orientation for tool changing.

Choosing the Right Technology for Your CNC Application

Versatility, power input, control style, and price are all essential factors in selecting the right motor and drive technologies for CNC machines. And with so many factors to think over, it can be overwhelming to make the final decision.

The best way to understand which tools fit your application is to speak to a KEB solutions engineer. We offer a wide range of cutting-edge motor and drive technologies, including DL3 servo motors. We’ll work through your goals to make the right choice for you and your customers.

KEB S6 Servo Drives: A Powerful Advantage for CNC Machines

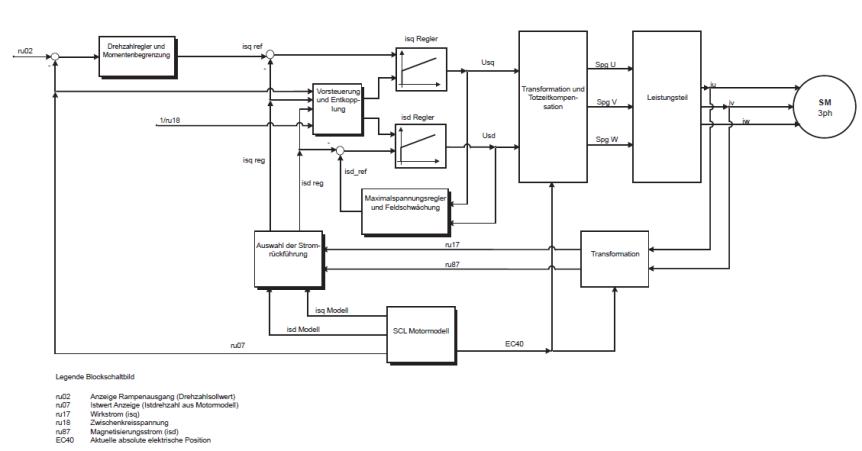

The S6 Servo Drive transforms efficiency for industrial CNC applications, featuring a 62.5µs current control loop for spindle motor operation. The S6 provides remarkable power efficiency, with module output frequencies up to 1600Hz.

S6 spindle drives support advanced SIL3 safety functionality and integrated brake control to ensure safety and dependability. Furthermore, S6 drives support multiple communication protocols—including EtherCAT and EtherNet/IP—allowing machine builders to standardize on a single drive platform.

Our spindle drives offer proprietary sensorless closed loop (SCL™) motor control as an alternative to basic volts/hertz control. This technology improves torque and speed regulation without encoder or resolver feedback, which lowers motor heating and improves motor shaft performance.

KEB leads the industry in flexible industrial communications options. Contact our team today for more info on our spindle motor drive platforms and how they can optimize your CNC machines for performance and reliability. We look forward to working with you.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.