KEB T6 Auxiliary Inverter – Setup Made Easy with Wizards and Apps

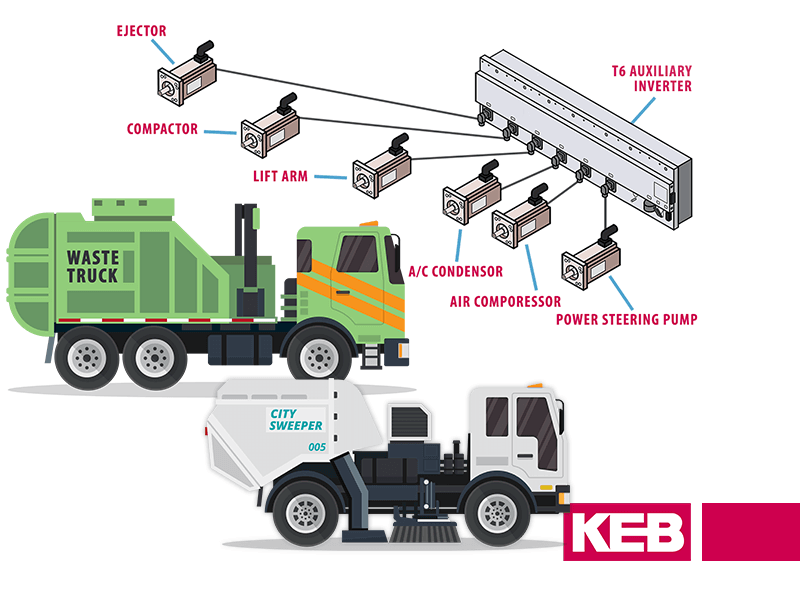

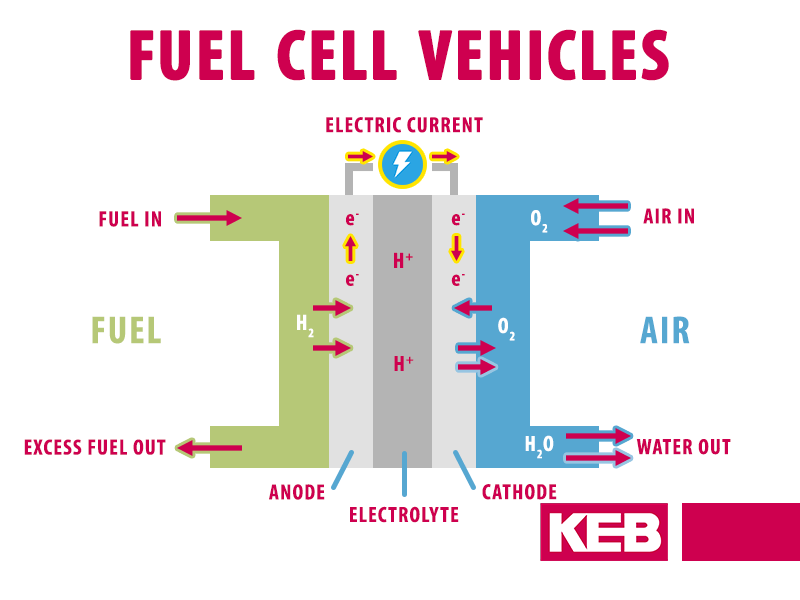

One benefit of a multi-axis inverter system is that is provides a uniform programming platform for multiple auxiliaries and motor types. This is particularly beneficial for electric vehicle applications which can incorporate several different electrified auxiliaries such as compressors, pumps, and fans as well as other equipment.

While this provides the flexibility to support a wide range of applications, each additional function or feature supported can lead to bulky manuals with too many parameters to sort through. Additionally, it can be difficult to develop customized features and quickly release new firmware. Rather, what systems integrators want is something that is intuitive, quick, and easy to set up or simply plug-and-play. Here, the KEB T6 Auxiliary Inverter provides two solutions: setup wizards and embedded apps such as the J1939 Process Data Gateway app.

Intuitive, Quick, and Easy…Setup Wizards

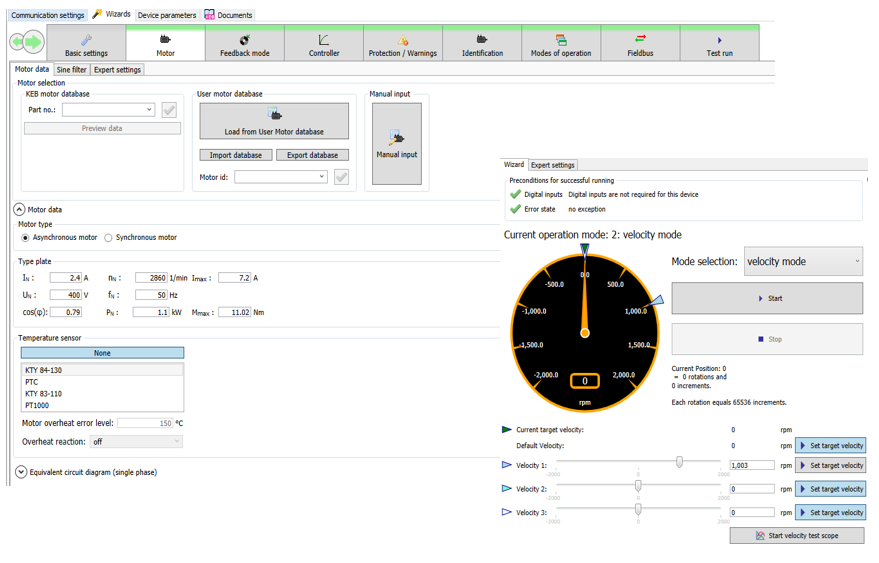

Wizards are graphical user interfaces which provide the user the most salient information needed for setup. Data entered into the fields are automatically linked to the corresponding background parameters. Additionally, wizards can be used to guide the user through start-to-finish sequences or automate a particular procedure such as a motor characteristic learn or a test run.

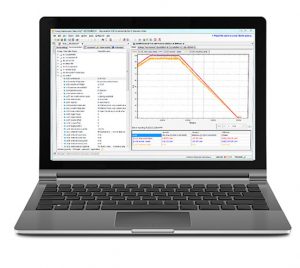

As standard, the free Combivis drive commissioning software for KEB inverters includes a startup wizard which includes sections for motor data entry, motor characteristic learn, speed settings and profile rates, fieldbus setup, and test run. Using this wizard, the user can be running a new motor type starting from default settings within a matter of minutes by having only the basic motor nameplate data available.

Plug-and-Play…Embedded Apps

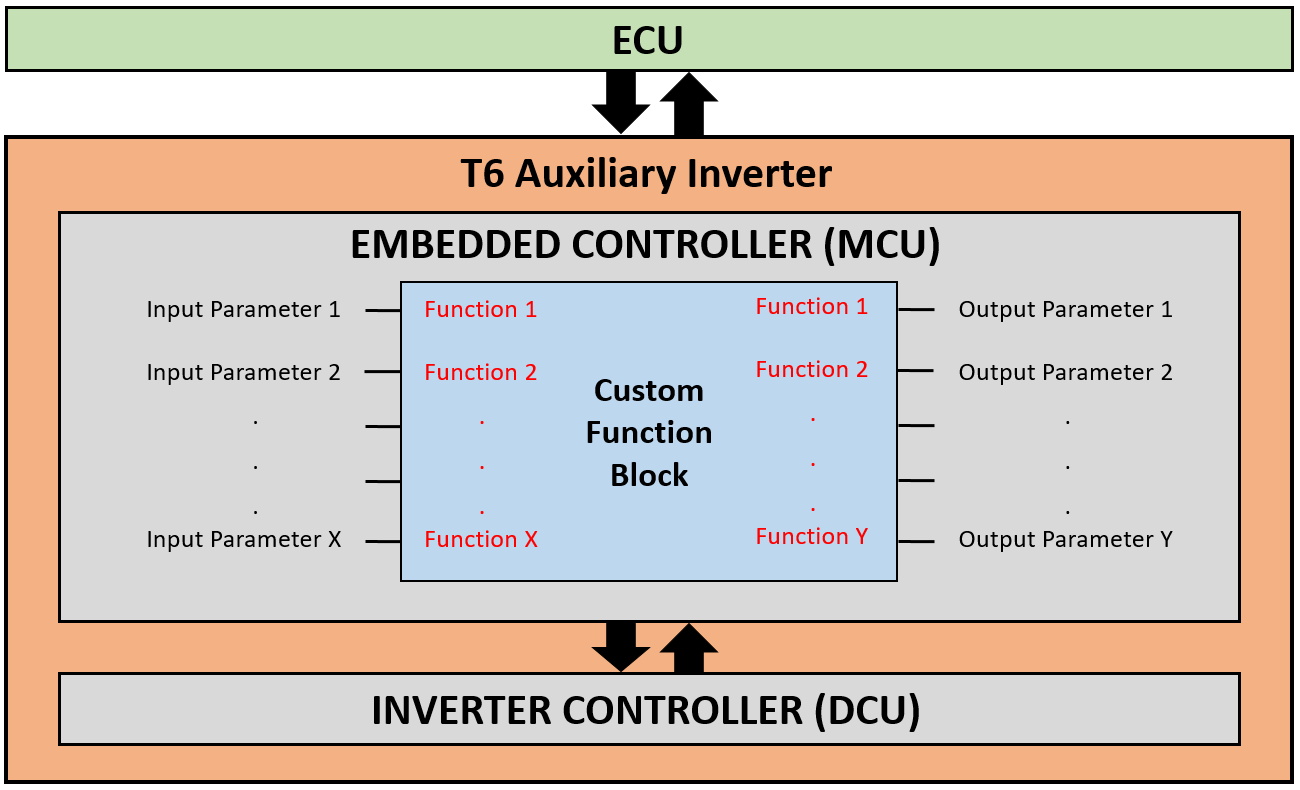

What are embedded apps? Embedded apps are similar to plug-ins or extensions added to an internet browser or programs installed on a computer operating system. A unique feature of the KEB T6 Auxiliary Inverter is that it has an embedded controller. In general, this acts as a central management hub and communications gateway and for all inverter nodes within the “system” (a T6 may have 1 – 6 independent inverter outputs). Additionally, the embedded control was designed with a modular software framework and contains a freely-programmable CODESYS-based (IEC 61131-3 languages) programming environment. This allows for easy integration of custom-created programs (and wizards), including those developed by third-parties. So, even if a desired feature is not natively supported by the inverter control itself, an “app” can be created to support it.

These apps can range from a simple velocity control with preconfigured I/O to OEM- or manufacturer-specific functions and operations tailored to the application-specific needs of a particular auxiliary. The former provides a solution for quick implementation for a variety of auxiliaries whereas the latter provides a plug-and-play solution. The modular framework also allows the selection of a different app for each inverter output. Thus, the T6 system can flexibly support a mix of various applications and component suppliers.

Application Example

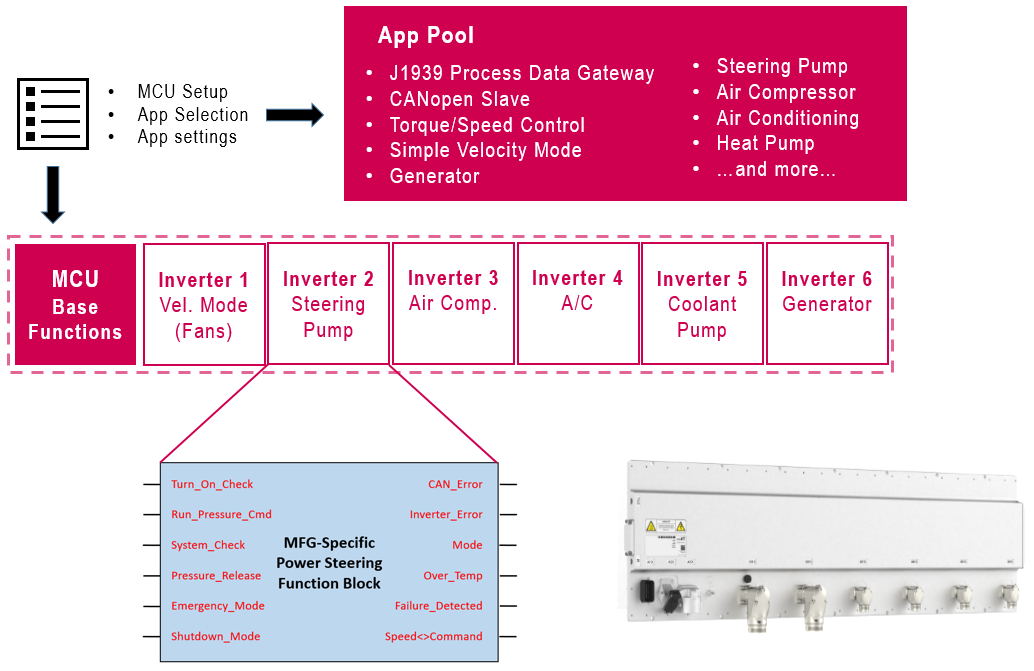

To put the app concept into context, consider an example of a T6 Auxiliary Inverter system with two inverter outputs: one for controlling a fan motor and a second for controlling a power steering pump motor. In the embedded control (MCU) there is a parameter to select an app from a pool of options for each inverter node. For a simple application like a fan, which may only need to run at one speed, an app such as the Simple Velocity Mode may be sufficient. With this app there would be an associated parameter for the speed command setting and the fan can then be turned on/off with a hardware switch.

For the steering pump motor, the manufacturer could create their own custom function block. This could include a parameter to select pre-configured motor data based on the model number, pre-configured CAN J1939 process data mappings, and special functions like a test mode to perform system checks at power on or a limited operation mode to reduce power consumption if the vehicle battery is low on charge.

Embedded Apps – An Improved Tool for OEMs

KEB’s embedded apps offer another way that OEMs can differentiate their product offering with the T6. Whether your application requires basic control or a high-level of customization, the KEB T6 Auxiliary Inverter embedded controller has the tools to make anything possible while keeping it simple with Wizards, yet versatile with customizable apps.

Want to discuss if the T6 would be a good solution for you? Contact a member of the KEB America T6 e-Mobility team or fill out the contact form below.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.