KEB brakes can be found in a wide variety of applications. From medical robots, industrial-sized cranes, theatre and live entertainment hoists, and many places in between. While used in these setups, they are most commonly used to stop or hold a load connected to a rotating shaft – either on a motor or on the machine’s primary shaft.

These rotary applications have featured KEB brakes for many years, but not everything that needs to stop is moving in a rotating motion. KEB brakes are also used in linear motion applications for both holding and dynamic applications.

Brakes for Linear Applications

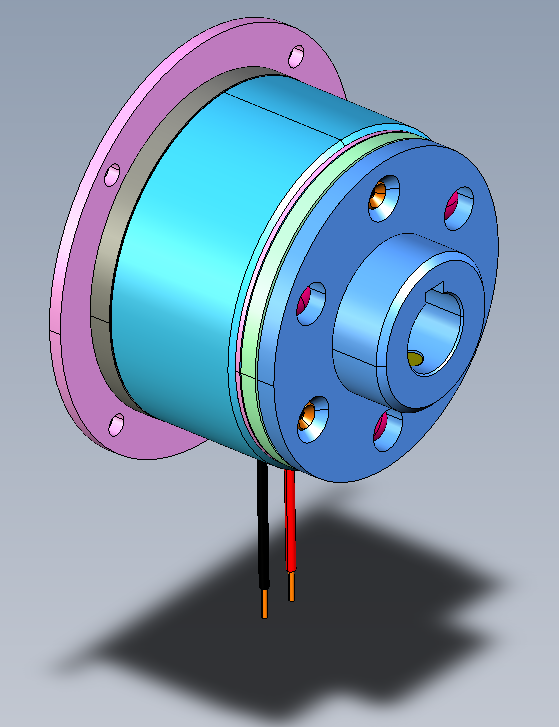

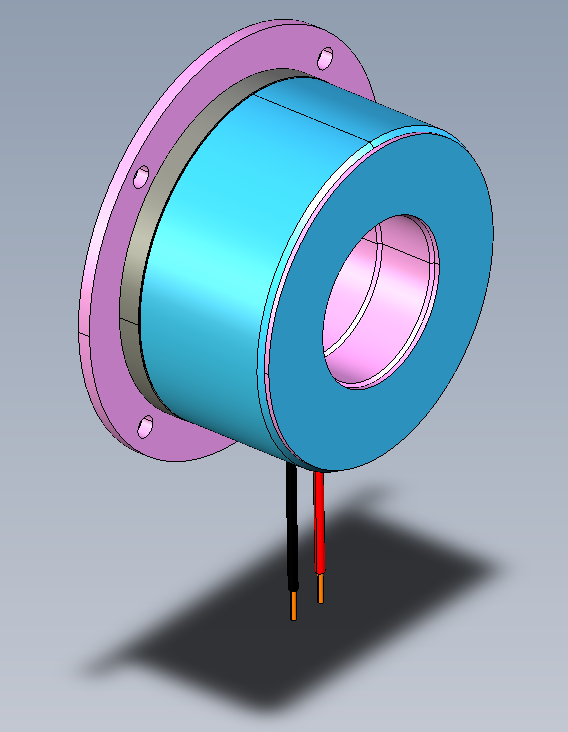

The KEB product used for linear applications is the P1 permanent magnet brake. As standard, for rotary applications, a PM brake (figure 1) comes with two main components, a magnet and a hub/armature assembly with a riveted flat spring in-between. When no voltage is applied to the electromagnet coil, the magnet pulls the armature across a small air gap and holds it against the brake magnet face, creating friction to prevent the shaft from rotating (How it Works Video). When voltage is applied to the coil in the brake it neutralizes the magnetic field and the armature is pulled back to the hub. There is a small air gap between the magnet and armature so the shaft is free to rotate.

|

|

| Figure 1: Standard Hub component for rotary applications | Figure 2: Standard Combiperm magnet |

Adapted Armature

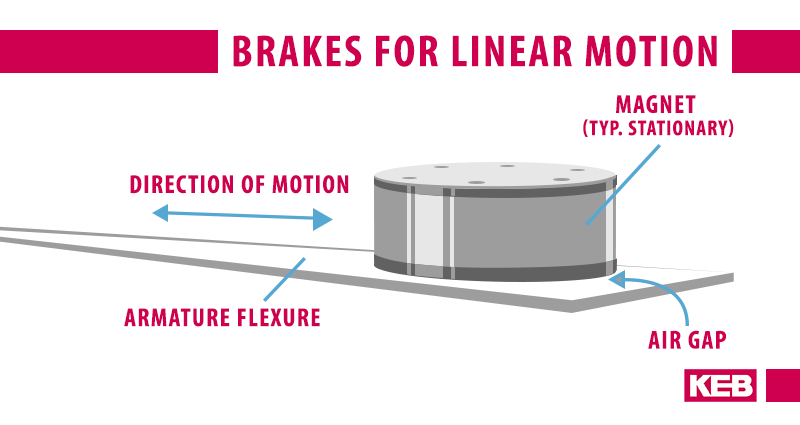

There is some adaption required to change from rotary to linear. No two systems are exactly the same, but in general, the riveted hub/armature is replaced by a flat armature located on a spring flexure. This flat armature acts as the secondary friction surface and will contact the face of the magnet when the brake is engaged. The small air gap between the armature and magnet remains. A benefit to this arrangement is that a standard magnet (figure 2) can still be used.

This secondary friction surface on a spring flexure works in the same as the hub/armature on the standard Combiperm, explained above. When no voltage is applied to the magnet, the secondary friction surface is pulled across the air gap and held in position against the magnet. When linear movement is required, the voltage can be applied to the brake magnet, this will neutralize the magnetic effect of the magnet and the flexure will pull the friction surface off of the magnet and the object will be free to move again until the voltage is cut from the brake magnet.

The biggest obstacle when using a linear brake is maintaining parallelism between the magnet and friction surface. The parallelism between these two surfaces is what controls the air gap, and if that gap gets too small or too large the brake will not function as it should.

KEB has designed and can manufacture flat armature pieces for customers. Alternatively, our customers can supply the part or integrate the KEB permanent magnet component into their assembly. Special consideration should be given to the material and treatment to make sure it has the right magnetic and coefficient of friction properties. In this design, either the magnet or the rail can be stationary while the other component moves. However, the magnet coil will be electrically powered and have electrical leads, which is usually the stationary component.

Bespoke solutions – Contact Us

While KEB does not carry a standard catalog of linear brakes, our team is full of creative engineers that have experience designing brakes for many different custom applications.

If you think a linear brake is right for your application contact KEB via phone or submit an inquiry on our website and you will be connected with an engineer to aid you in choosing the best brake for your application.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.