Electric motor brakes are used to decelerate or hold motor loads when the power is cut intentionally or accidentally. KEB has been supplying motor brakes since our founding – this gives us more than 48 years of experience.

Beyond our core brake technology, KEB is able to offer custom designs which help motor manufacturers during assembly and meet the application requirements. This post gives an overview of KEB’s motor brake technology and some of the value-add we provide motor OEMs.

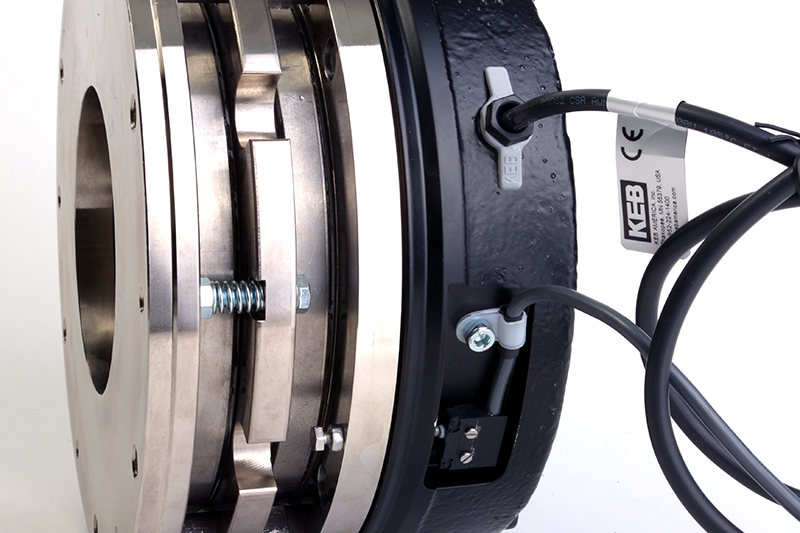

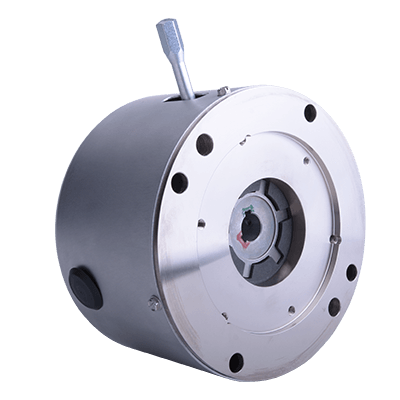

DC Spring-Set Brakes

KEB specializes in the design and manufacture of DC spring-set brakes. Compared to AC Brakes, DC brakes offer a number of advantages including: simple operation with no linkages, less adjustments needed, less ongoing maintenance.

When we replace AC brakes, it is typically in those really demanding braking applications where there is a high cycling rate. The solenoid and linkages in the AC types do not stand the abuse and wear or fail prematurely.

See how KEB Spring-set Motor Brakes operate

KEB can offer brake coils wound for any voltage including battery power machines using 12VDC and 24VDC. Using a KEB bridge rectifier, AC power is easily converted to DC power for the brake.

Motor Brakes to handle Tough Applications

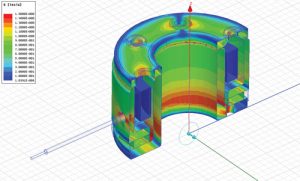

KEB brakes are designed for demanding industrial applications. Our friction linings and coil voltage tolerance all have internal safety factors built-in. This becomes important for demanding and safety-critical applications. As standard, KEB’s spring-set brakes are CSA listed and UL can also be designed for.

KEB can offer special brake solutions as the application requires. We can offer IP65 brakes for washdown and outdoor installations. We can offer high energy brakes for applications where the brake is required to stop very large loads repetitively.

We offer silent brakes for theatre hoists and elevator motors that are noise sensitive. We offer special brakes for applications in moist and humid environments.

If you have a demanding application, chances are we already designed a solution for the applications.

Mounting Options

Because we have internal design capabilities here in Minneapolis, we can customize our brakes to meet the requirements of the motor design.

Most commonly, KEB supplies the brake assembly and our customer mounts it to the outside of a prepared end bell or mounting flange. Optionally, KEB can provide the mounting flange or NEMA C-Face adapter plate.

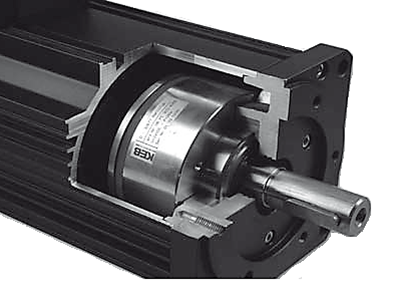

We have also done designs where the brake is mounted inside the motor housing (e.g. servo motor brake). The advantage is that the customer is able to get an IP65 designed brake. However, this should be used for holding brake applications only as the brake is not easily serviceable.

Besides the mounting flange, we can also provide other customized options. We can provide extra long leadwires if needed, or special connectors. Additionally, we can provide special hubs or rotors that are located off motor shaft features (step or snap ring).

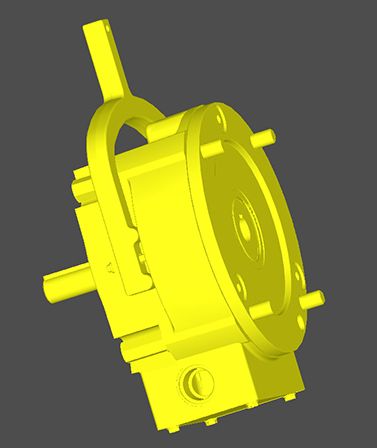

Double C-Face Brakes

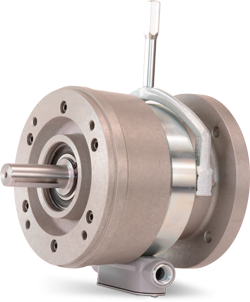

One option customers like for both new and retrofit installations is KEB’s Type 17 Double C-Face Brake. The Double C-Face Brake is a power-off DC spring-set brake. The design includes an integral NEMA input flange and output flange and shaft.

See how KEB’s C-Face Brake operates

This brake is typically mounted in between a NEMA C-Face motor and a gearbox. Some customers prefer this brake as it is modular and the gearbox, brake, and motor can all be serviced or replaced individually.

The Type 17 brake is offered with a variety of different magnet voltages and includes a conduit box for making the wiring connection. As standard, this product is designed with NEMA 4 protection and includes a manual hand release.

The product can be paired with 56C through 286TC NEMA motors.

KEB – Your North American Brake Partner

Electric motors are used in a wide variety of applications, with most of them requiring a brake. With KEB’s history, experience, and reputation of supplying the highest quality of brakes we are confident that we can find the brake for your application. Local design and production capabilities have allowed us to help motor manufacturers by offering better quality products with shorter leadtimes.

Even if you have a custom application requiring a different brake style (permanent magnet or power on brake) – feel free to contact us and one of our Engineers will take a look and specify the correct brake for your application.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.