Non-proprietary Elevator Controllers & Drives – KEB Machine Room Vids #02

The second video in our series of Machine Room visits. In this episode, we discuss non-proprietary elevator controllers and the advantage of using KEB elevator drives.

Advantages include: all needed tools for adjustment, documentation to aid support, designed for long product lifecycle, etc.

Check out the first video in the series on our YouTube channel.

So non-proprietary controllers are controllers that have been designed to be maintained and serviced by any number of parties. They’re not closed or restricted as far as the information and who can service them.

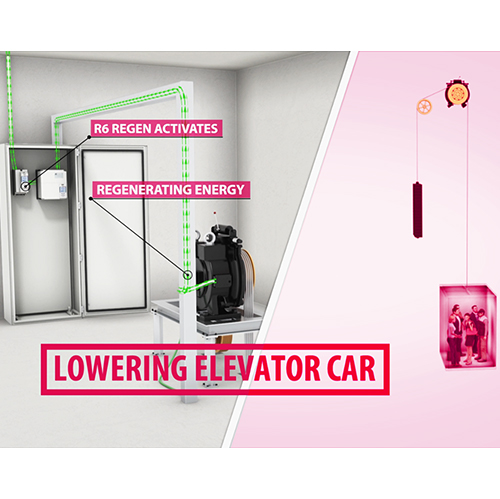

So today we’re at an application, this is an MCE controller, an I Control. MCE is one company that provides non-proprietary controllers. So this is the KEB elevator drive and R6 line regen unit. Everything ships with the drive that’s needed to service it, install it, maintain it. All the adjustments can be done right on the drive itself so there’s no proprietary cables or dongles. The keypad is central so through the keypad all the adjustments that are needed can be made. Additionally, diagnostics can be reached there without any sort of additional tool.

If you want you can connect to our software. The software is free and it’s available for download on our website.

A second distinction to make is in the hardware itself. This is not special hardware, it’s based on standard industrial drive hardware that KEB uses in other applications worldwide. The F5 series is built on standard industrial drive platform for KEB, which means that it’s been designed for a long product lifetime. KEB shoots for twenty years in the product lifetime. The F4 series which we just discontinued was over twenty years. The F5 series is going on fifteen years and still has a long life. So that’s definitely one important consideration – is the product going to be available and maintainable, not just today but in the future?

One other important distinction as far as documentation and support. Some systems can be pretty closed as far as who has access to the information – what different parameters do, different things like that. By philosophy KEB is very open, so every drive would ship with a manual basically that has this information. It’s not closed information that’s just available to KEB employees or anything like that so it helps in cases where the job might change hands or somebody else might be servicing the elevator than originally installed it.

So if you have any questions about KEB’s integration into non-proprietary elevator controllers you can contact us here or give us a call. Thanks.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.