Optimizing high speed motors with KEB

This is the second part of our short series on how KEB VFDs can be used in high speed applications. In our last post we discussed the benefits of KEB technology in high speed applications.

In this post we’ll talk about some of the options you have for optimizing high speed motors by KEB and some commercial considerations to partner with KEB.

KEB sine filter technology Maximize system efficiency

High speed motors may run with very small rotor clearances on the bearings. Rotor heating becomes a concern as any elongation or expansion of the rotor due to excess heat can cause the rotor to impact the bearing.

In applications requiring very low harmonics on the output waveform, KEB produces a line of high speed sine filters to filter the output voltage and current waveform to a near sine wave to keep the rotor heating to a minimum.

KEB SCL software is designed to run with an output sine filter. The software also incorporates an electronic filter to avoid resonance issues between the drive/sine filter/motor combinations.

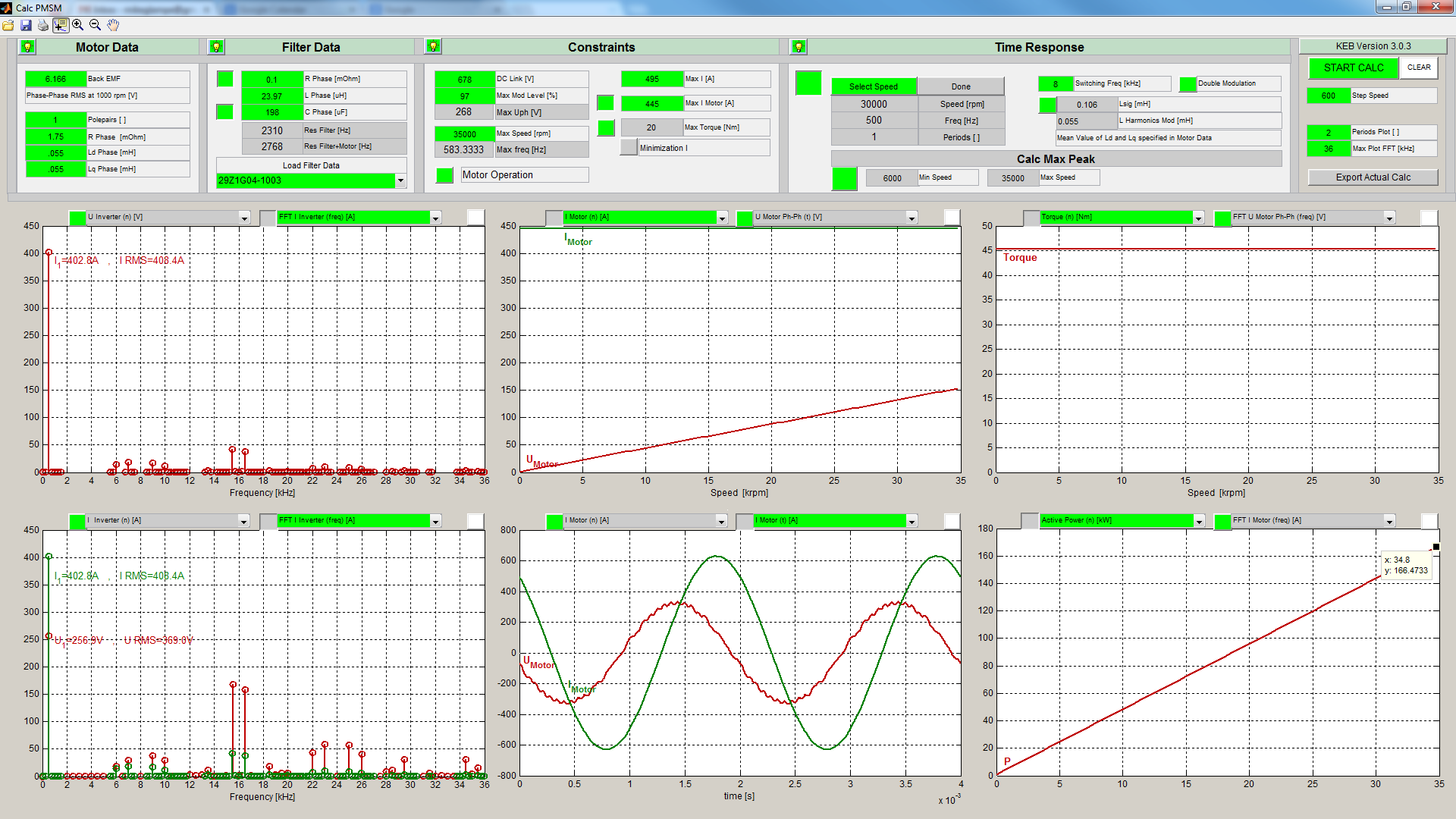

KEB simulation tool The right system for your motor

High speed motors and their bearing systems may have limitations such as resonance and excess heating when operating in certain conditions. The selection of the proper components for the system is paramount to avoid any potential issues.

To aid in the selection of the proper components, KEB has developed a simulation program which utilizes the motor design data. The simulation program allows KEB engineers to run a simulation with or without output filters and view the expected output voltage and current waveform.

Potential system resonance points can be identified and proper steps taken to minimize any issues with the actual system. Utilizing this powerful simulation technology, KEB engineers can work with customers to provide the optimal solution in technology, efficiency, and cost.

KEB options The best solution for the application

High speed motors are used for their high efficiency and high power density. Many high speed, high power motors utilize liquid cooling for maximum power output. In addition to the traditional air cooled VFD heatsink, KEB drives are also available in liquid cooling configurations.

When running at higher output frequencies, there is additional heat that must be dissipated. Liquid cooling provides an efficient way to remove this added heat. KEB has options for utilizing water/glycol cooling or refrigerant cooling.

KEB is your partner Flexible, powerful, proven

There are a lot of commercial reasons to partner with KEB for your high speed motor application. First, KEB uses our standard drive hardware and topologies to control high speed motors. We are not using a one-off custom drive design which can only be “matched” with one type of motor and applied in a very limited scope. Because standard hardware is used, both economy and quality benefit from the increased scale.

Secondly, KEB is not a boutique drive manufacturer. KEB is a global manufacturer so users are assured that the product carries the leading global product certifications like UL and CE. Along with the certifications, up-to-date documentation and an extensive support network are available.

Finally, KEB is proven. With over 100,000 installed drives specifically running high speed machinery, KEB is the leader.

If you’d like to learn more about KEB control and automation solutions, you can reach us using the form below.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.