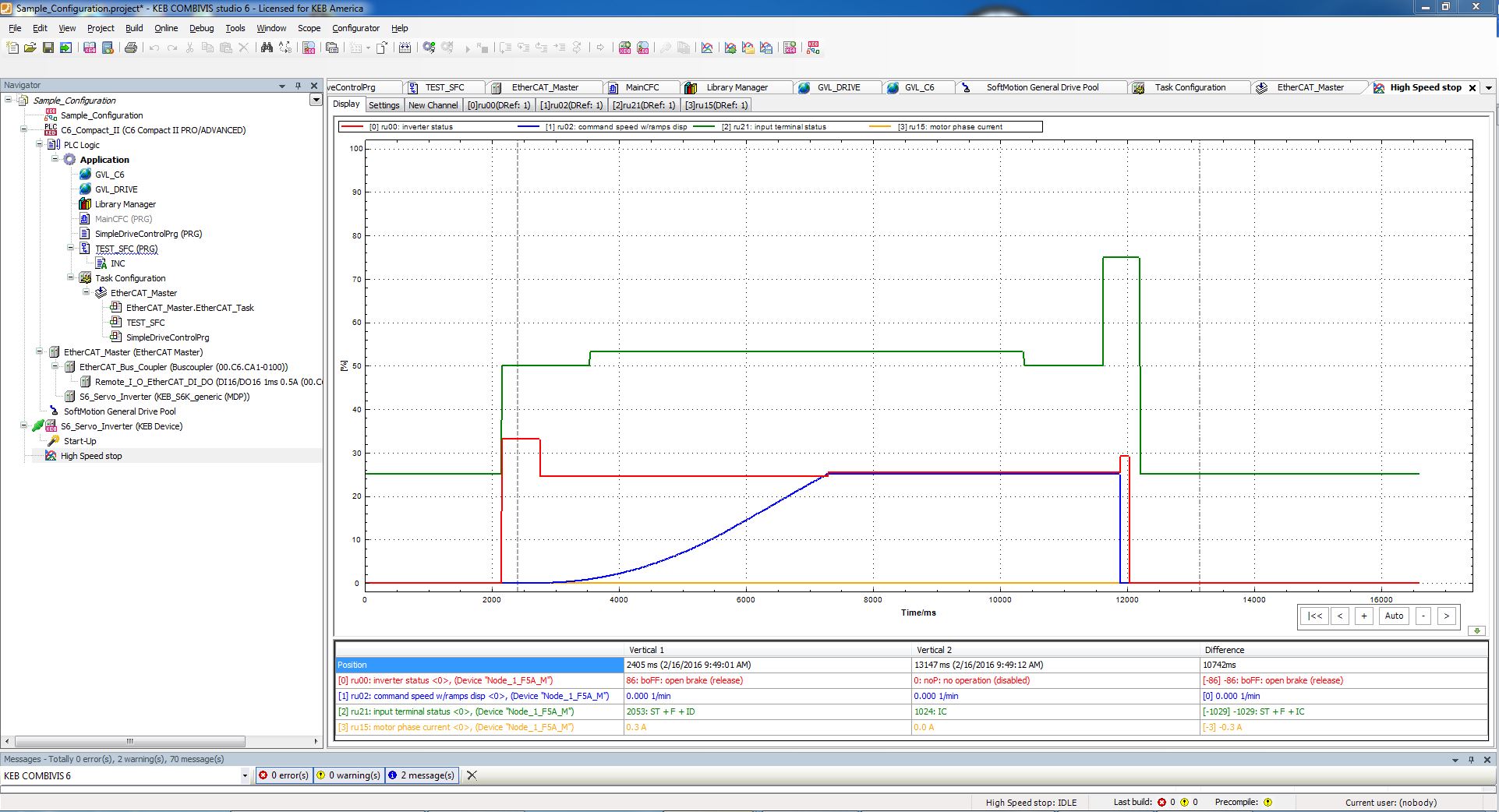

Oscilloscope for Combivis VFD Software

The KEB Combiscope is a powerful tool that is included with KEB’s free Combivis 6 VFD programming software.

This post describes how the Combiscope tool is typically used for setup, troubleshooting, optimization and validation of a KEB VFD applications with functions such as an oscilloscope.

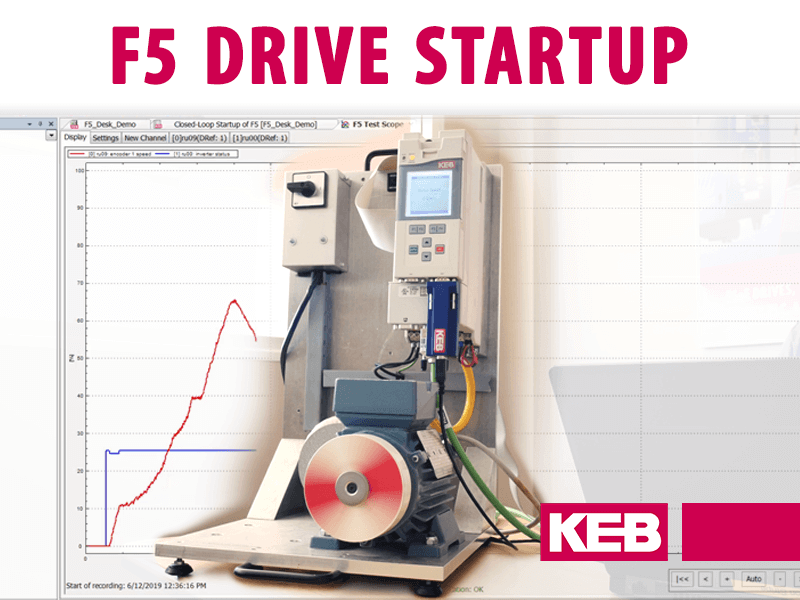

Set-up & Commissioning

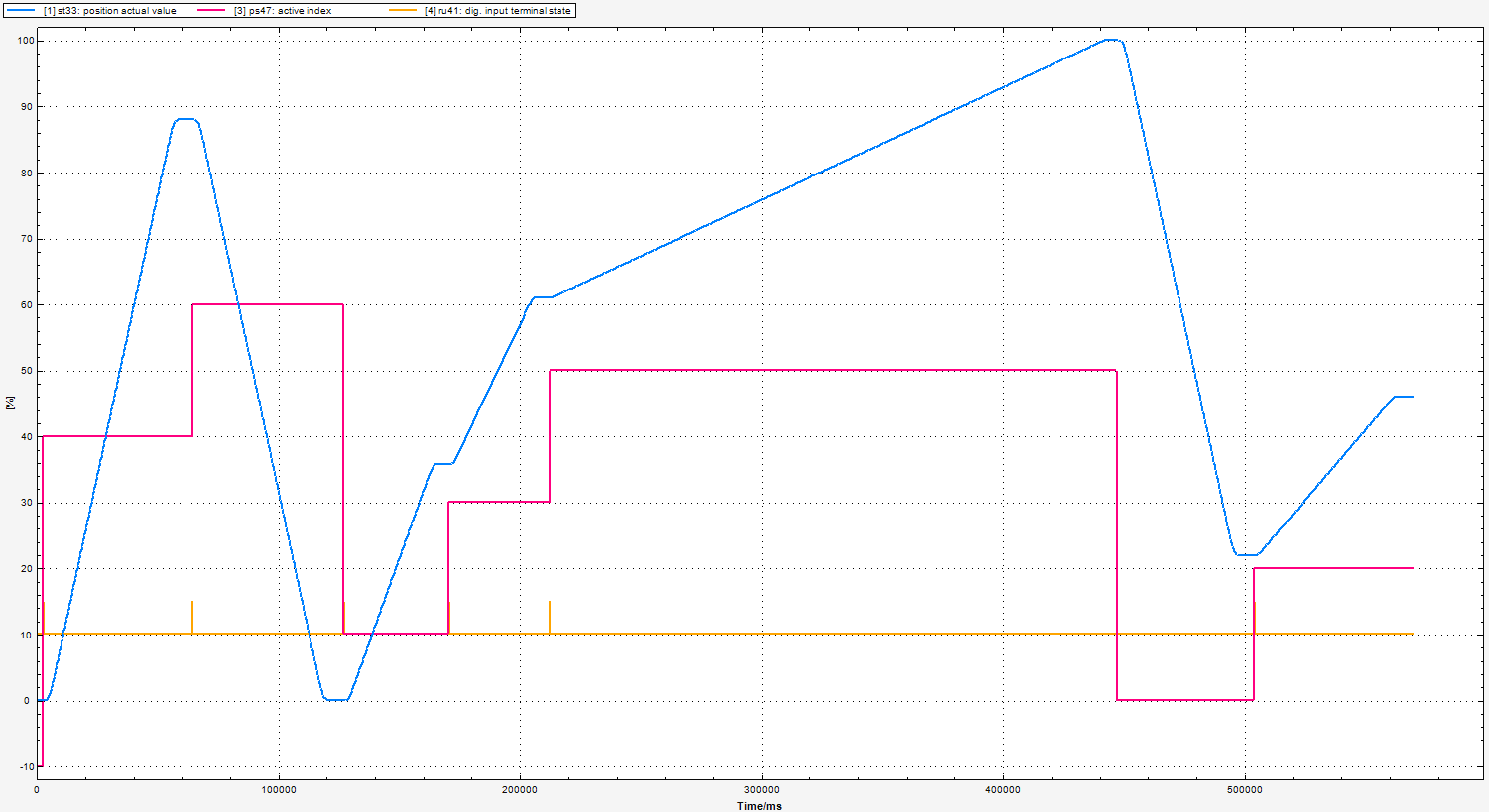

The Combivis Scope allows the user to plot out up to 16 parameters from the KEB drive in real-time. KEB VFDs have many diagnostic parameters available which give a clear picture of the operation of the system.

By utilizing the available diagnostic values measured by the drive, Combiscope can be used to monitor these values in real time as the VFD is in operation. A few examples of how the Combiscope can be used during the setup process are:

- Plotting the output current may allow the acceleration rate to be set to avoid high current spikes during starting;

- Plotting the DC bus voltage would allow the deceleration rate of the application to be set to avoid having to use a braking resistor;

- Plotting the actual encoder speed in the closed loop system would allow the speed gains to be optimized for the best system control

- Plotting the motor torque in a closed loop system would allow the torque limit to be set at a high enough value to allow normal operation, but limited to protect the mechanical parts of the system.

Troubleshooting

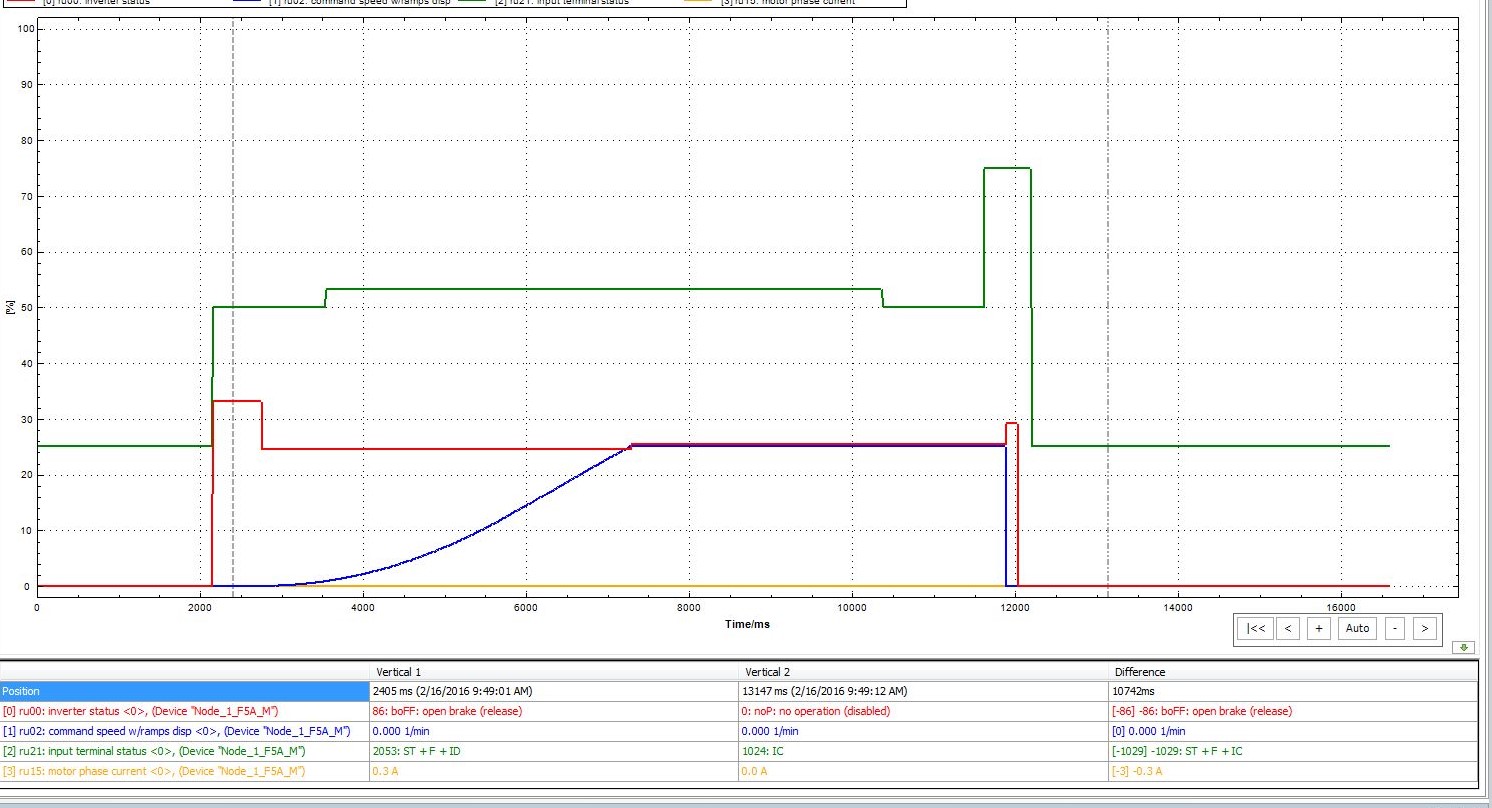

For troubleshooting, using the Combiscope can be a valuable tool to help shorten the process. Using the scope to plot out the input terminal status can help determine if inputs from a PLC are correct based on the required operation. Monitoring the output current to the motor may show a mechanical issue in the system due to binding or wear.

Optimizing Drive Sizing (cost)

Optimizing the VFD can help reduce the cost of the overall system. Using Combiscope, the output current to the motor can be monitored as the machine cycles. The scope trace can then be saved and utilizing the rms calculation functionality, the rms current can be calculated over a cycle of the system. By determine the actual utilization of the motor, the size of the VFD may potentially be reduced for subsequent versions of the machine.

The optimization may also be helpful if the same machine may be used for various types of products (packaging, plastic extrusion, etc.). Depending on the economics of the machine line, using different size VFD’s for machines built for specific specifications may allow the system costs to be reduced. In addition to the drive cost being reduced, further savings may be found in smaller gauge wire, smaller circuit breakers or fusing and reduced enclosure cooling.

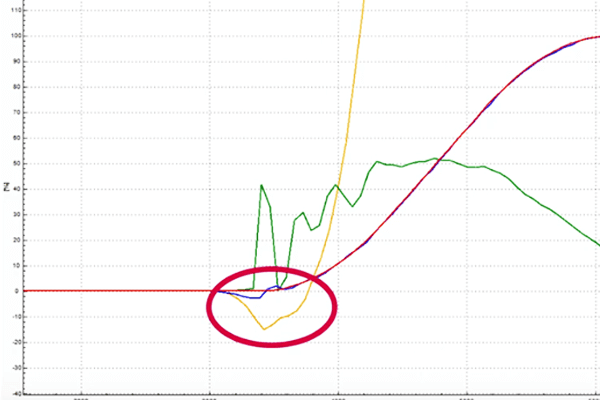

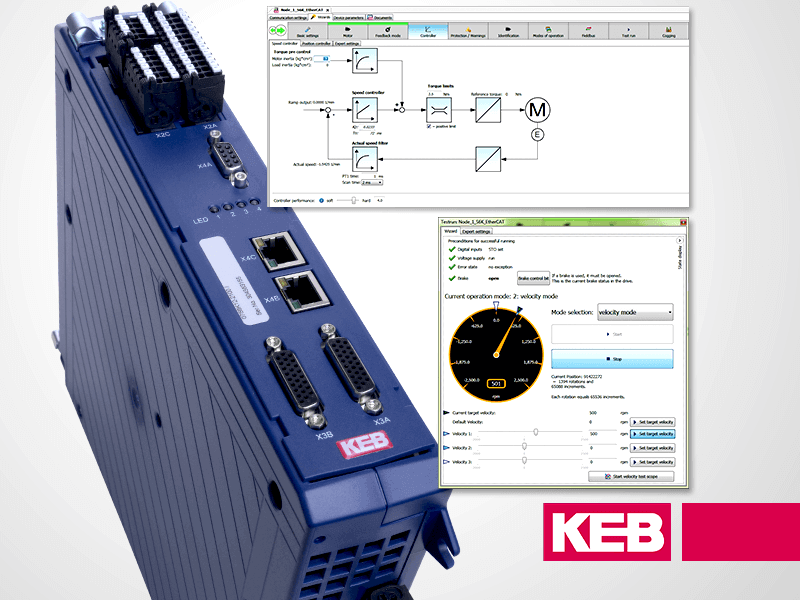

Optimizing System Performance & Gain Adjustment

KEB Engineers can assist with sizing and selection of the automation components for your application. The sizing and selection are based on the available data, which may include a move profile and loading information of the machine. Using the Combiscope software, the response of the actual system can be compared the calculated values. One example of this may include using the Combiscope to plot out values to use to calculate the load inertia of the system. By verifying the actual inertia is consistent with the values used during the design phase; this may verify that a braking resistor is sufficient to stop the system in emergency stop mode.

Another use may be to use the Combiscope to save a record of the operation of the system at the time of commissioning. This data can be saved and recalled at a later time to compare to current operating conditions. This may help to determine if mechanical components are wearing or if the loading of the system is being used outside the design specifications.

Conclusion

As part of the free Combivis 6 programming software available for the KEB VFD, the Combiscope has many valuable uses during the design and testing phase and during the aftersales support of a system. The KEB Combiscope is a simple, powerful tool that will help Engineers, Service Technicians and machine users to get the optimum performance from the VFD application.

Contact KEB today to discuss your VFD application.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.