Permanent Magnet Brakes – How they Work

This video describes how KEB permanent magnet brakes work. KEB’s P1 permanent magnet brakes are commonly used in servo motor and robotic applications because they are compact and provide zero backlash power-off braking.

VIDEO TRANSCRIPT

KEB’s P1 Permanent Magnet Brakes provide power-off braking. The brakes provide best-in-class torque density and are preferred when space is a constraint. And because the brakes have zero-backlash they are commonly used in servo motor and robotic applications. Features like clamping hubs or special connectors can be designed as needed for the application.

A magnet housing contains an electromagnet coil and powerful rare-earth neodymium permanent magnets. Without power, the permanent magnets create a magnetic field which deflects a flat spring and pulls an armature into the magnet’s surface. The metal on metal contact creates a brake torque. Since the armature is connected to the hub with a riveted connection, the shaft is locked with zero backlash.

When the electromagnet is powered with DC voltage an electromagnetic force is created which opposes and negates the force created by the permanent magnets. In the absence of a magnetic circuit, the flat spring pulls the armature back to the hub. With a small air gap between the magnet and the armature the shaft is free to rotate.

If you’re interested in hearing more about our P1 Permanent Magnet Brakes feel free to give us a call or an email, or you can read more on the permanent magnet brake product page.

Let's Work Together

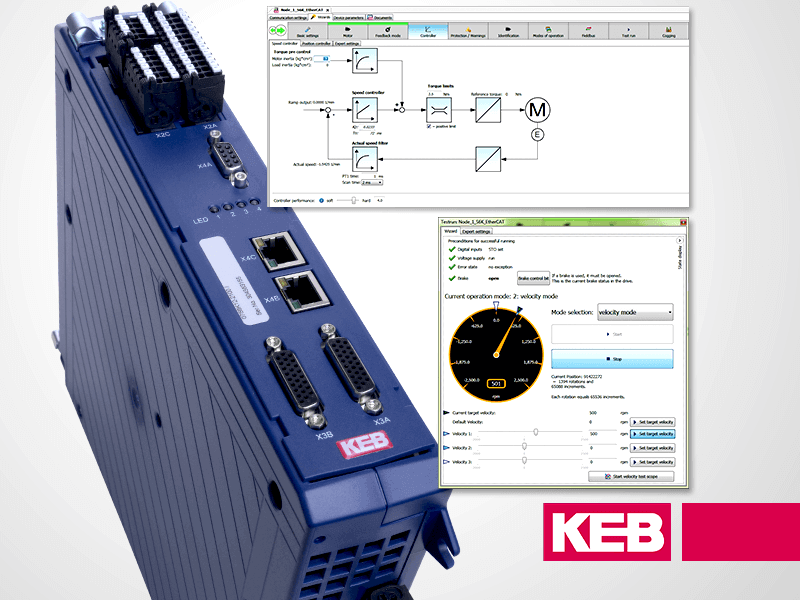

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.