Some VFD applications require there to be as little audible noise as possible. Theatre hoists, elevator drives located next to a Penthouse Suite, and testing machines for audio equipment are all projects I have worked on that had strict noise requirements. This post describes the common sources of audible noise and 4 things a user can do to reduce noise in their VFD application.

Audible Noise

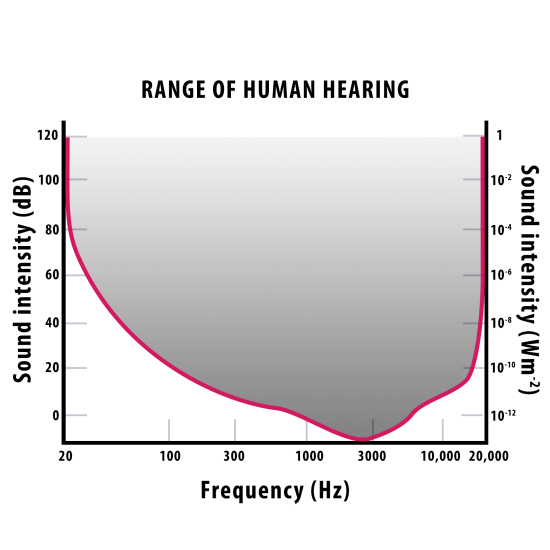

The first point to make is that I am talking about audible noise, not high-frequency electrical noise. A good rule of thumb is that the human ear has a frequency range from 20 Hz to 20 kHz. In general, this is the frequency range we are talking about when reducing audible noise. It might even be a bit less than 20 kHz as your hearing response attenuates as you age or if you’ve attended too many rock concerts.

A good rule of thumb is that the human ear has a frequency range from 20 Hz to 20 kHz.

Electrical noise is another thing altogether and gets into the much higher MHz band. If interested in reducing electrical noise, you can check out this post.

When trying to reduce audible noise, it is helpful to first understand where it is coming from – what is the source of the noise? Is it coming from the VFD itself? Or is the noise coming from the motor? Or possibly from the machine frame or rails the motor is mounted to?

If you are able to first identify the source of noise, then some of these items can be addressed:

#1 – Cooling Fans

Probably the easiest thing (if possible) is to not run the cooling fans. KEB drives have thermostatically controlled fans on the VFD. This means that the fans only turn on when the VFD heatsink is above a certain temperature threshold. In most applications, the fans are mostly off. Thermostatically controlled fans have the added benefit that they increase the lifetime of the fans – one of the first and most common parts to fail on a VFD.

Related Video: Replacing a KEB S6 Cooling Fan

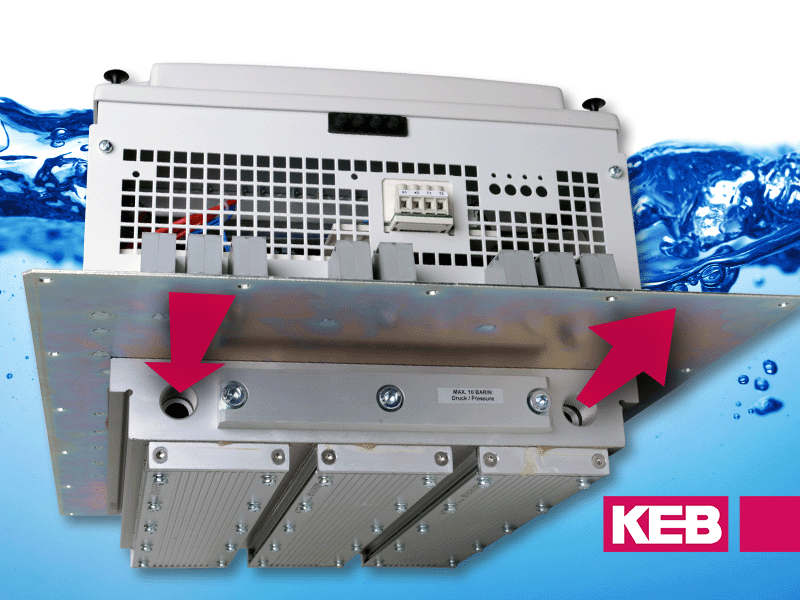

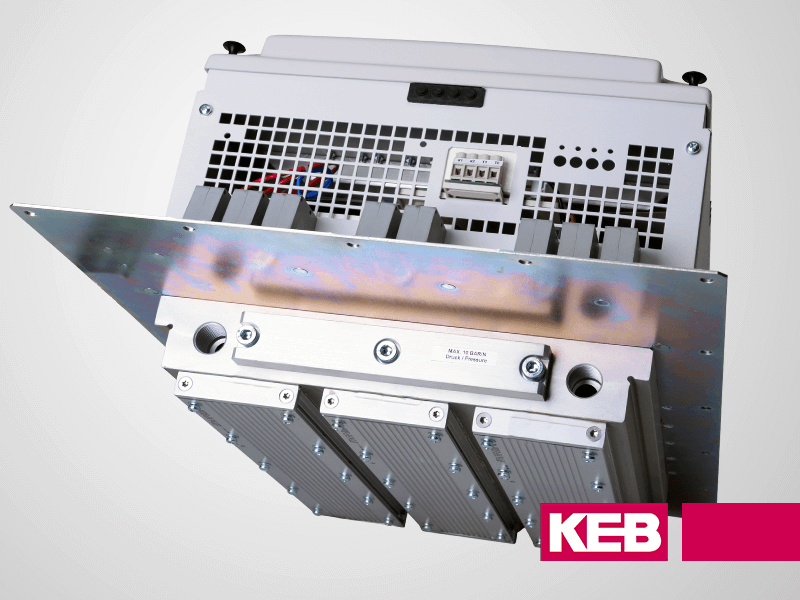

But sufficient cooling is required and provides a long operating lifetime to your VFD. So if the application is demanding and the fans run often, an alternative would be to use a flat-back or liquid-cooled heatsink. KEB liquid-cooled drives use water or some coolant to cool the heatsink instead of forced air.

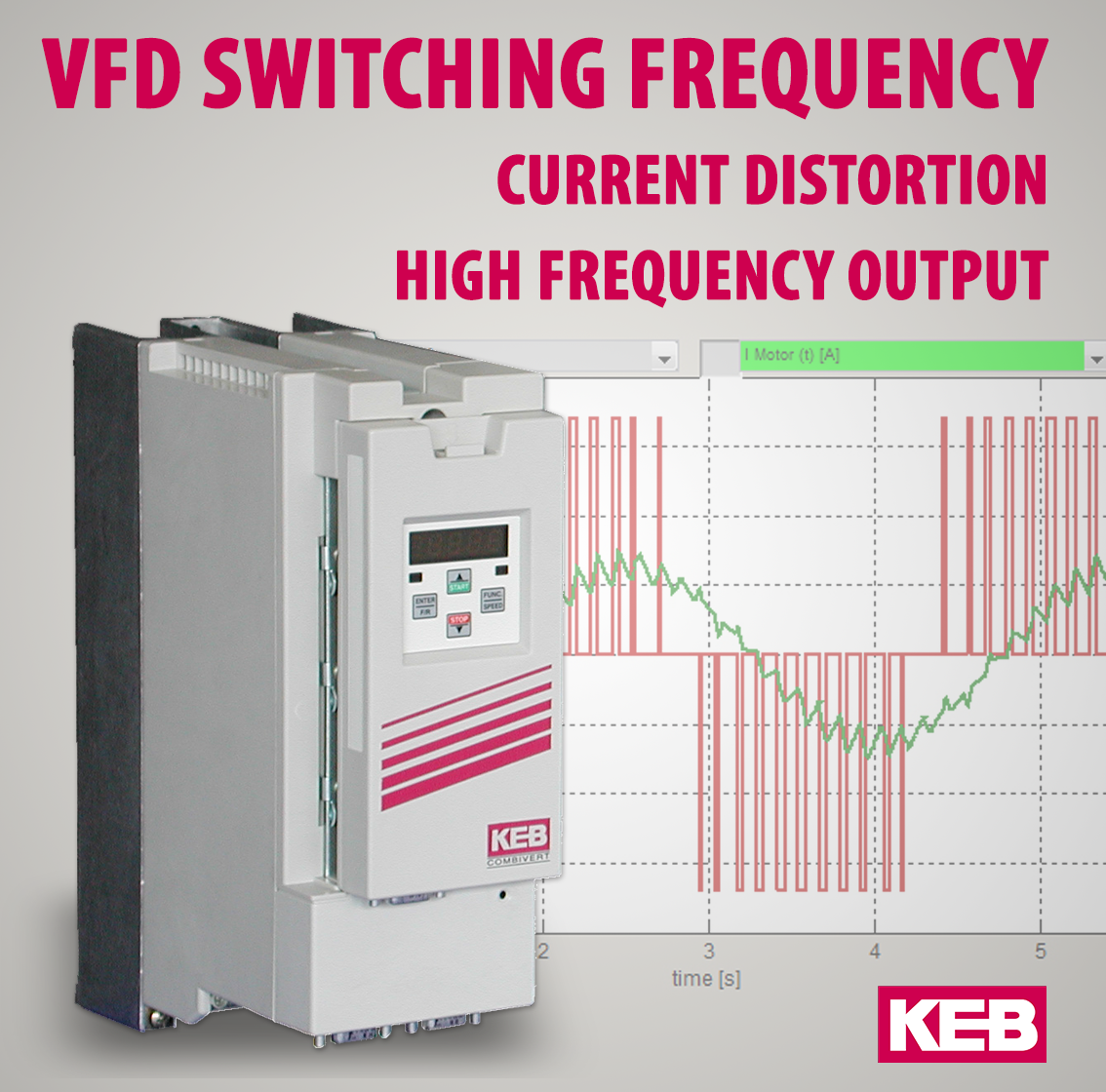

#2 – Switching Frequency

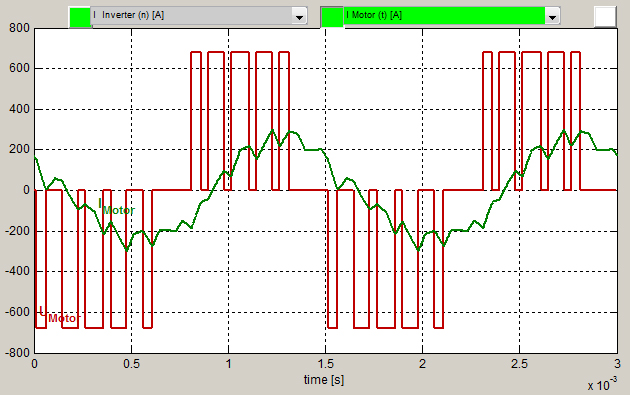

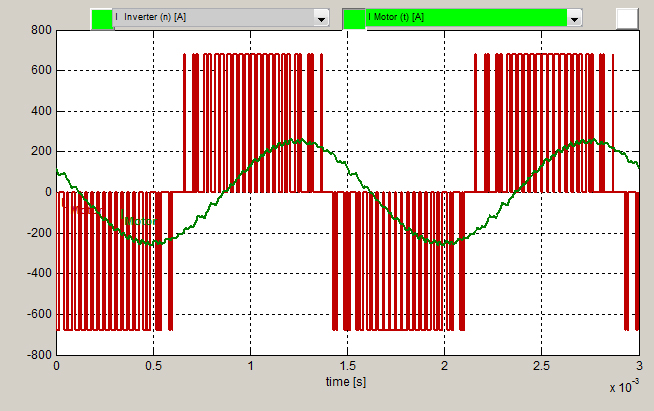

A second common source of audible drive noise comes from the output IGBTs which are switching at a very high frequency. Common switching frequencies are 2 kHz and 4 kHz. 2 kHz is right in the mid-band of the human ear frequency response.

Related Topic: How do Switching Frequencies Affect Harmonic Distortion

Lower switching frequencies have the advantage of less heating which leads to higher output currents on the drive. However, switching at 2-4 kHz is audibly much more noticeable.

The fix here is to increase the switching frequency to the point where it is inaudible to the human ear. KEB drives can be switched up to 16 kHz which is higher than most drives. In my experience, 16 kHz switching is inaudible. At that point, other ambient noises are more discernible than the drive switching.

The tradeoff in moving to 16 kHz is that the drive must be oversized to handle the increased heating with more IGBT switching. A general rule of thumb is that the drive size (and cost) doubles when upsizing from 8 to 16 kHz.

In my experience, an 8 kHz KEB drive is nearly silent and offers a good tradeoff between cost and noise performance. 16 kHz is reserved for the most demanding applications.

It should also be noted that audible noise varies between VFD manufacturers. So even though the switching frequencies are the same, one still might be audibly louder. For example, I have heard some competitor drives that are set to “16 kHz” that still produce quite a bit of sound. I suspect there is more to the audible noise than just the rate of IGBT switching. I suspect the quality of the PWM signal and the driver circuitry also plays a big part. These details cannot be found in datasheets and are only found by testing side-by-side.

#3 – System Resonance

If the noise comes from the motor or mechanical parts it could be due to a system resonance. This can be identified if the noise happens at a certain frequency or a harmonic order of that frequency. If possible, the motor should be run at a frequency that does not excite the system. The solution might be as simple as lowering the motor speed or overspeeding beyond the critical frequency. Alternatively, some drives have notch filters or skip frequencies that can be adjusted where the drive adjusts its output frequency to avoid the critical frequencies.

#4 – Motor

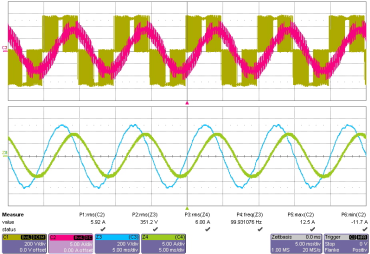

Another common source of noise is from the motor itself. Both AC induction and PM servo motors use thin steel laminations in the stators. Laminations of high-grade electrical steel are used because they reduce eddy current losses. However, when excited at certain frequencies, the laminations can vibrate and emit audible noise. Increasing the switching frequency to the motor typically provides the motor with a better, waveform. The “cleaner” waveform results in a quieter and cooler operating motor.

Additional filters like KEB’s Sinewave Filters or dV/dt output chokes also help improve the quality of power seen at the motor leads and can help reduce audible noise from the motor.

KEB offers filters that are capable of 16 kHz switching. Many 3rd party filters are not rated for high frequencies so this is something to check when looking at filter solutions.

Sometimes the noise from the motor is not so significant when bench tested. But it sounds totally different when it is mounted in an actual installation. The reason might be that the mounts are acting as a tuning fork and amplifying the noise that is originating in the motor.

Sometimes you can add vibration dampeners to the motor mount but be careful that the motor is still well-grounded to the machine frame.

Reducing audible noise can be tricky. These are some places to start. I would be interested in hearing if you have experience with audibly noisy applications and what you did to solve them.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.