A crane hoist is a prime application example of a motor that cycles back and forth between motoring and generating mode? When the crane lifts a load, electrical energy is delivered from the utility to the motor and it goes into “motoring mode”. As the load is lifted, potential energy is stored in the system. The amount stored depends on the mass of the load and how high it is lifted.

Eventually, when the load is lowered – the motor goes into “generating mode” and the energy from the mechanical system flows back into the VFD in the form of current.

The problem is that most VFDs have input rectifiers that act as a one-way street. They allow energy to be delivered from the source to the motor, but not the other way. Traditionally, this excess regen energy is dissipated as heat across a power braking resistor. However, some applications make the use of braking resistors very difficult due to the environment, duty cycle, and heat generation.

Regen units offer an alternative to braking resistors. This post provides some considerations for their use in Crane and Hoist applications. For a basic overview of regen drives and four-quadrant operation, see the video below.

Hazardous Environment Cranes

Cranes going into hazardous environments face unique challenges. Traditionally, one challenge has been using a braking resistor with a Crane VFD. In a typical crane application, the VFD is mounted inside an electrical enclosure and the braking resistor is mounted outside the enclosure. But in explosion-proof applications, it is not possible to mount the resistor outside the cabinet.

What often happens is the resistor must be mounted outside the hazardous area which leads to an extremely long conductor and conduit run. The additional cost for this can add up quickly.

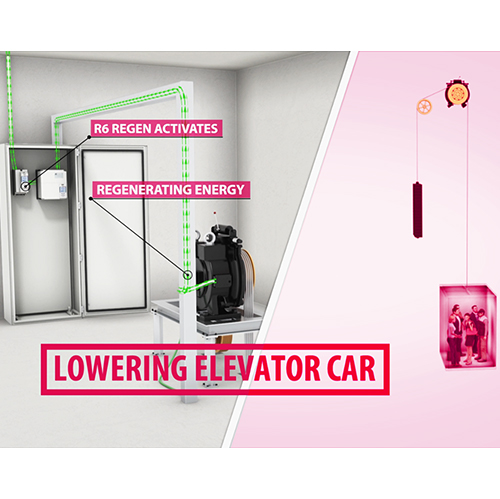

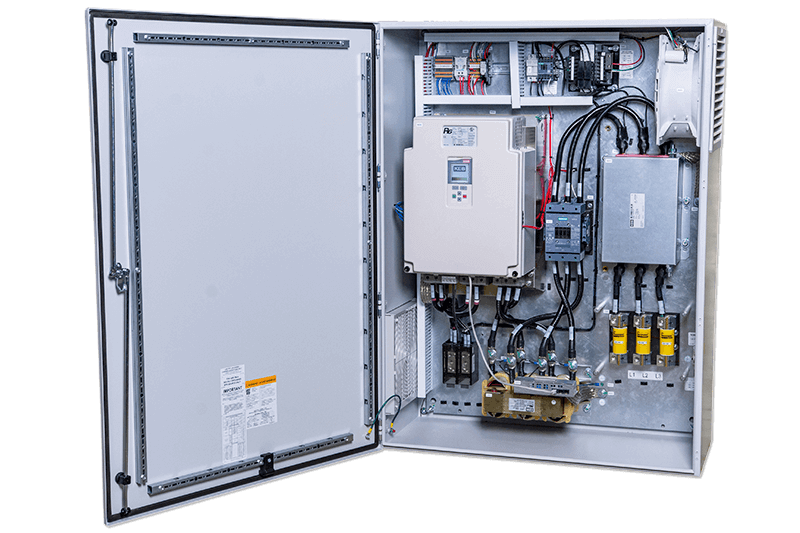

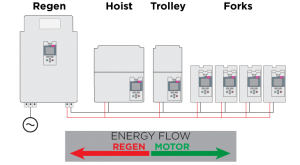

As an alternative to using braking resistors, a KEB R6 regen unit can be used. The R6 unit is mounted inside the explosion-proof enclosure and is DC-bus connected to the crane VFD. Instead of dissipating the regenerated energy as heat, the R6 units returns regenerated energy to the building power supply where it is consumed by other electrical loads.

The R6 unit uses innovative power hardware which allows for a very compact size – up to 49% smaller than competitor units. This real estate becomes valuable when considering the cost of explosion-proof enclosures.

Going Green – Less consumption, save $$

The other reason a user might look to apply a regen unit is for cost savings. Using an R6 unit will result in less power consumption and electrical energy costs.

The amount of returned energy will largely depend on the efficiency of the hoist used, the size of the hoist, and how often the crane is loaded and operational.

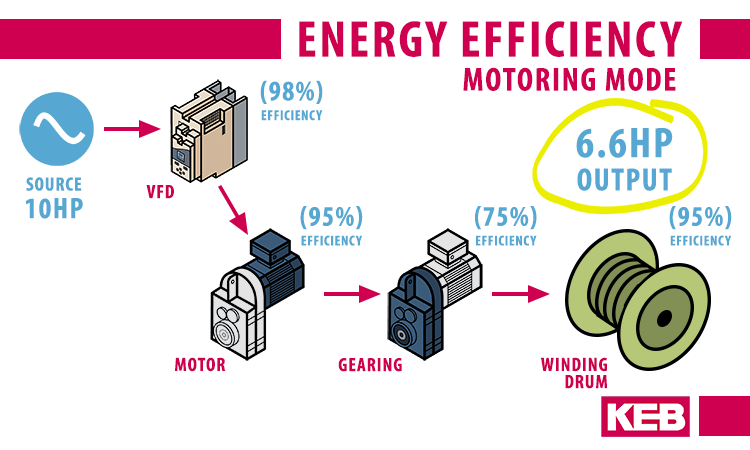

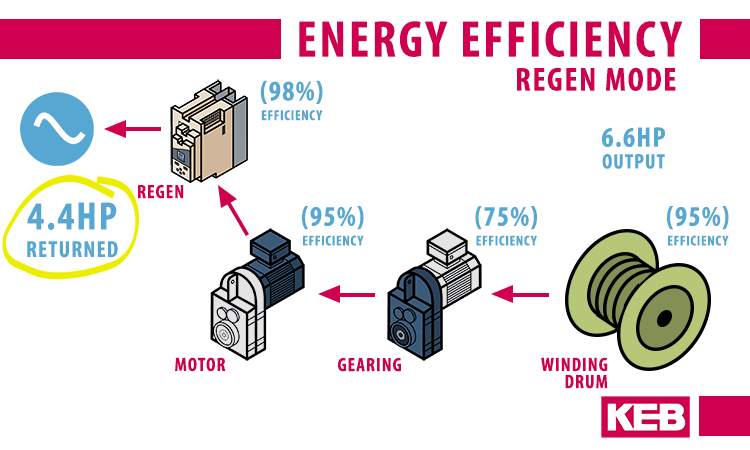

We can look at a sample application with system losses to see how much energy is actually returned. The energy must be delivered to the system, and must be regenerated. So the system losses actually happen twice. A system might look like this:

In this theoretical example, 10Hp of input power equates to 6.6Hp at the hoist drum after transmission losses.

As the load is lowered this power must pass through the transmission components again and there are additional losses. So the 10Hp of system input actually results in 4.4Hp of regenerated energy.

This is only an example, so bigger cranes will have more regenerated energy. Additionally, using more efficient components has a big impact on returned energy and ROI. For example, switching from a right angle worm gear to a right angle helical bevel gear might result in 40% more regen power.

Conclusion

In summary, there are different reasons a customer might look to use regen drives for their overhead crane. It is not only about energy saving and reducing electrical energy costs. Using regen drives might solve challenges associated with braking resistors, particularly for hazardous environment applications.

Would you like to know more about KEB’s R6 Line Regen units? Talk to a KEB engineer today.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.