Remote Monitoring for Material Handling Applications

Material handling is a rapidly evolving application that powers the safe, efficient movement of materials and products across the supply chain. As these assets transition from manufacturing to warehousing and distribution, they touch various equipment designed to optimize this important handling process, including controls, conveyors, and even automatic guided vehicles (AGVs). But therein lies a problem: if any of this equipment becomes damaged or inoperative, the material handling system takes a costly dive in productivity until it’s fixed.

This is why machine builders in the material handling space (across aerospace, automotive, plastics, and many other industries) are investing in remote monitoring. Let’s discuss the utility of this powerful technology to see if it’s the right choice for your own supply chain and workflow.

What is Remote Monitoring for Material Handling?

Remote monitoring is a technology that gauges the performance and condition of industrial machines in the field. It’s available for a range of material handling equipment, including AGVs, conveyors, shipping sorters, and even automated storage and retrieval systems. Using sensors for temperature, vibration, collision, water detection, and more, these solutions help material handling teams keep tabs on the status of their equipment, detect problems early, and make more proactive decisions regarding maintenance.

Remote Monitoring in Predictive Maintenance

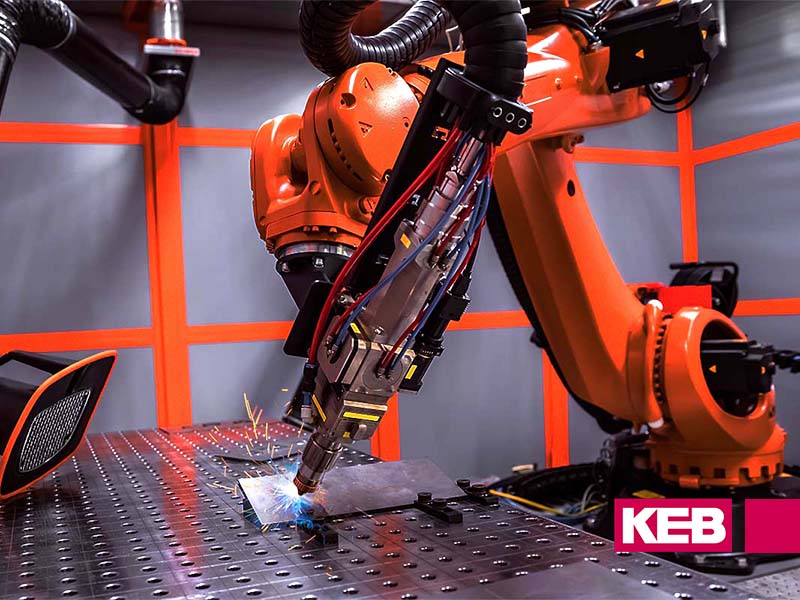

Predictive maintenance empowers material handling teams to resolve equipment or system problems more reliably. Through remote monitoring and sensors, early signs of performance issues in guided vehicles, conveyors, or even industrial robots (such as abnormal temp or vibrations) can be detected—before the system is negatively impacted by downtime. This results in a more stable workflow, where repairs can be made and machines serviced at convenient times.

Remote Monitoring for Overall Equipment Effectiveness (OEE)

Remote monitoring solutions provide valuable insight into the performance of equipment. Material handling teams may access logged data from sensors to assess and improve the efficiency of their equipment. These insights can be captured and compared across time—and even between machines—to benchmark progress and get a transparent look into the effectiveness of each machine or process.

How Remote Monitoring Impacts Your Bottom Line

Material handling plays a vital role in moving, protecting, controlling, and storing materials or products as they ultimately transition into the hands of customers. By supporting this lynchpin process, remote monitoring positively affects the supply chain as a whole in numerous ways:

Shortened Delivery Times

When products are efficiently and safely transported from each phase of the supply chain, they reach consumers significantly faster, creating a powerful advantage for manufacturers over competitors.

Lower Handling Costs

Material handling systems that minimize downtime and equipment problems contribute to a more cost-efficient supply chain, saving costs throughout the manufacturing, transportation, and distribution cycles.

Improved Safety

By nature, material handling involves interaction between operators and large, potentially dangerous equipment. Remote monitoring helps ensure that machines used across this process are running properly and safely, reducing risk of injury for operators and other workers.

Better Inventory Control

Proficient material handling gives companies greater control over inventory management, allowing them to reduce inventory by quickly and dependably moving material and products through the workflow.

A Shift Towards Automation in Material Handling

Remote monitoring is yet another example of how automation impacts material handling. Like AGVs and AS/RS (automated storage and retrieval systems), this automated monitoring solution is being used to make material handling operations more time-efficient, consistent, and predictable.

Rather than constantly checking up on machines and reacting to problems during maintenance visits, handling teams can automatically monitor these issues and resolve them when they emerge. This is all part of a larger movement in the machine-building space, with cloud and IoT (internet of things) technology reshaping our approach to analytics, preventive maintenance, and proactive problem-solving.

Innovation Through Remote Access Tools

Remote monitoring is just one of the many advantages of remote connectivity for machines. Machine builders are investing in internet-connected devices to generate revenue while providing more value to end users. For example, remote connectivity allows machine builders to quickly and decisively respond to equipment problems or failures, without the need for expensive, time-consuming service calls.

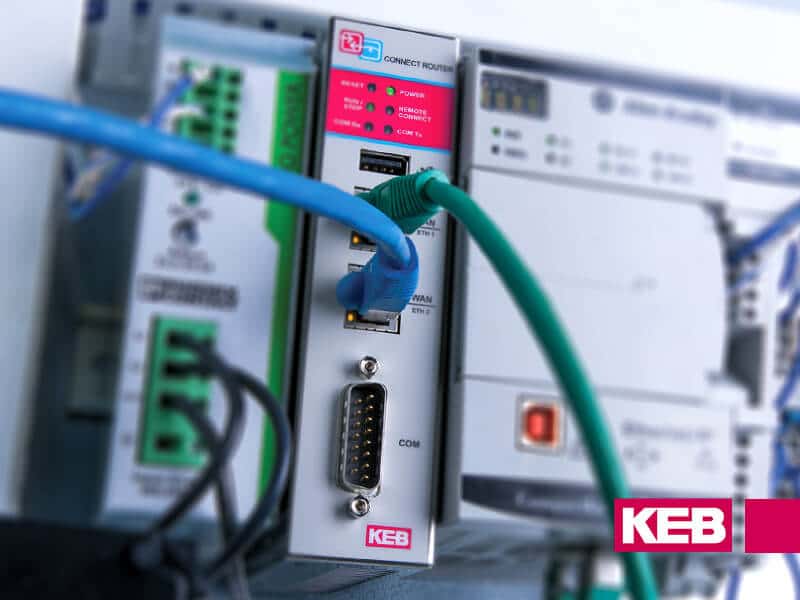

Routers for Remote Monitoring & Maintenance

For the best results, machine builders should utilize industrial-grade connectivity products to create a safe and secure connection to machines in the field, whether that’s an automated vehicle for transporting raw materials or an overhead crane for heavy-duty movement of products.

KEB’s C6 Industrial VPN Router provides remote access to both new and legacy PLCs, with support for all Serial or Ethernet-based PLCs as well. This durable router is built for even the toughest industrial environments—and can serve as a data logging and remote monitoring tool to improve machine performance.

Streamline Material Handling with KEB

KEB offers a full portfolio of flexible automation and control products for material handling, including powerful drives to optimize system performance. Contact a KEB solutions engineer today to learn more about our tools for remote monitoring and material handling efficiency.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.