Residential Elevator Brakes

KEB is perhaps best known in the Elevator market for our Elevator and Regen Drives but we also manufacture brakes for elevators.

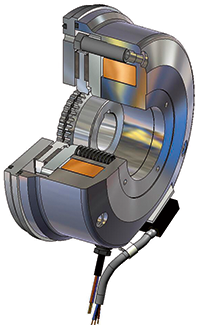

KEB manufactures armature-actuated brakes (not caliper or drum-style brakes) which are well suited for smaller motors used in residential elevators, MRL, and dumbwaiter applications.

This post provides an overview of KEB brakes and why they are well suited for elevator applications.

Spring Applied Operation

The KEB America Combistop brake is electrically released and spring-applied. Sometimes these brakes are referred to as “failsafe brakes” because they engage when power is removed. This is the type of operation a designer will want to use in lifting, hoisting, or safety-related applications.

Designed and Manufactured in the USA

Many advantages KEB brings to the table are because our brakes are engineered and produced outside Minneapolis, MN. This means that we are able to use our core brake technology and design features as the application require.

From a supply chain standpoint, this is also a big advantage to our North American customers. Local manufacturing means that lead times are typically shorter and the product is not originating overseas.

Quiet operation

One product feature that KEB is able to offer is noise-reduced operation. A loud ‘clunking’ noise or a rattle from the brake as the elevator car levels is not desirable.

Various design features are incorporated into the KEB brakes which reduces the noise levels. Overall, this provides a much more pleasant experience for the elevator passenger, especially in a residential or MRL elevator application.

There are actually several different noise reduction options at various performance/cost levels depending on what our customers require.

NPT Fitting for Conduit

KEB brakes can be fitted with an NPT fitting which allows the electrical conduit to be run and connected directly to the brake. Additionally, if needed, we can offer our brakes with extended leads to be fed back to the power supply or elevator controller.

Hand Release

Typically, an elevator brake must have the ability to be released even without power (consider a power outage). For this, KEB brakes can be fitted with a manual hand release. When the hand release is pulled back, the brake disengages and the shaft is free to rotate.

When released, the hand release returns to its location and the brake engages. This operation is sometimes referred to as a “dead man’s brake” and is an important feature for safety applications.

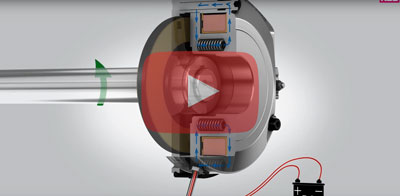

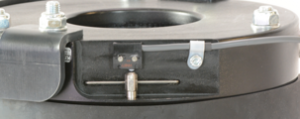

Microswitch

KEB also offers a microswitch option on our brakes. A microswitch is typically used to provide feedback to the controller that the brake has actually engaged. It adds an element of safety as a brake confirmation is needed before power is cut to the motor.

It also has operational benefits. When incorporated with the controller and various brake timers, a microswitch can reduce lining wear and allow for a much smoother brake transition.

Flanges

KEB typically also provides mounting flanges with our brakes. The flange serves two purposes. First, it provides a suitable friction surface for the friction lining. This means the surface finish is designed to KEB’s required specifications. Second, it acts as a heatsink if the brake is performing a significant amount of work.

KEB can design and provide custom flanges as well. A popular option is to use a C-Face flange which can then be mounted onto a C-Face motor end bell.

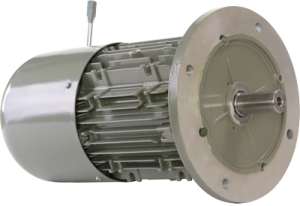

Double C-Face Option

A spring-set variant we also provide for elevator applications is our Double C-Face brake. The advantage of the Double C-Face brake is that it can be paired together with an off-the-shelf NEMA C-Face motor. Overall, the solution can be more cost-effective especially when an encoder device is added to the equation. Motors with a brake and encoder are not cheap.

If you are already using C-Face motors, this brake option is a great choice if you have a need to retrofit brakes on existing installations. KEB Double C-Face brakes are offered up to 256TC frames and are available with different magnet voltage options.

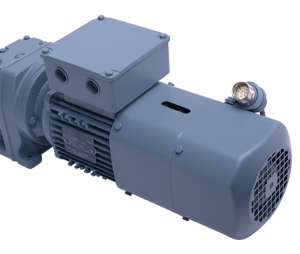

Gear(motor) with brake

The final configuration where our brakes get used in elevator applications is when paired with our integral gearmotors. The KEB gearmotor product is designed in Germany and assembled here in the US. The product offering is extremely flexible and has a lot of product options like encoders, shrink disc mounting, and brakes.

The brakes are again what set KEB apart from other manufacturers. We are able to offer all of these high-performance brake options (noise reduced, microswitch, etc.) which are very well suited for elevator applications.

And it all comes together packaged with our residential elevator gearmotor product. So these are savings to elevator manufacturers in the form of reduced labor and installation time.

KEB – Your Automation Partner for Residential Elevators

Do you have an application in mind? Our engineers would be happy to discuss – contact us today!

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.