Austria-based Rubble Master is the world leader in compact mobile crushers. For 30 years, the company designs and manufactures a robust fleet of mobile screen units, crushers, and stockpiling conveyors for the mineral processing, aggregates, and material recycling industries.

In the 2010s, Rubble Master developed a hybrid (diesel-electric drive) crusher that combines the advantages of diesel-driven and electric-powered crushers without increasing the size of the machine. For this reason, a specific type of servo drive was needed to control the new mobile crusher.

Rubble Master worked with KEB Automation to optimize its Combivert F6 VFD in a prototype. After testing and tweaking the solution, Rubble Master found the perfect drive product for the RM 120GO!, and a long-term strategic partner in KEB.

Heavy-Duty Servo Drives for Outdoor Applications

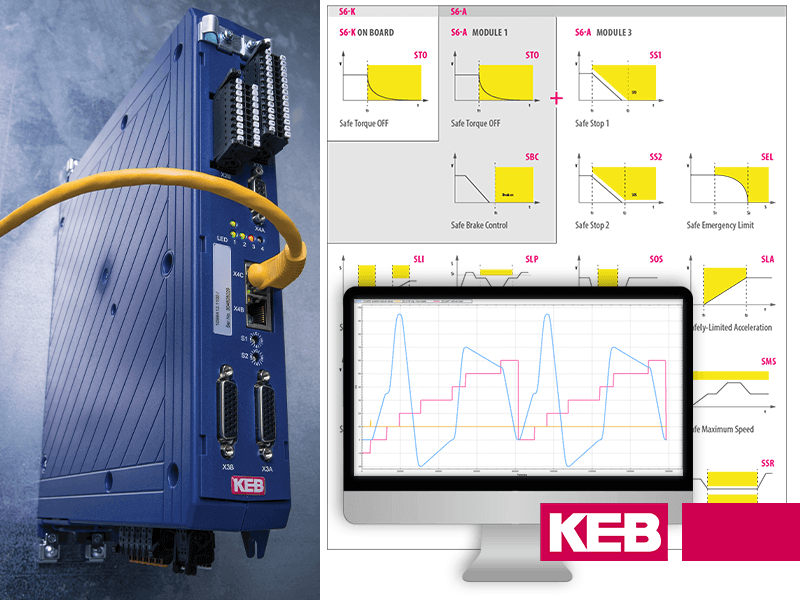

When Rubble Master designed the RM 120GO! hybrid crusher, now branded as RM 120X, it required a compact-sized, liquid-cooled servo drive to control the three-phase asynchronous motor. The company turned to KEB Automation and its Combivert F6 VFD due to its size, features, efficiency, and safety.

“We needed a variable frequency drive that was small enough and be water-cooled,” said Jeffrey Ton, Rubble Master’s head of powertrain and controls. “KEB had the perfect solution.”

Rubble Master selected the KEB F6 (size 7 version) with an output of up to 200kW. It features functional safety, heatsink, control card options, and supports five Ethernet-based network communication protocols. In total, the power range of the F6 extends from 2.2 to 450 kW, which meets the requirements for the RM 120GO!.

Markus Gaggl, Rubble Master’s Chief Technology Officer agrees, “With this new product, we are setting standards in the electrification of our industry. KEB is the right partner for this.”

Reliable Servo Drives In Harsh Environments

The RM 120GO! hybrid crushers are powerful heavy machines weighing in at 35 tonnes. Its mobility and flexibility give aggregate producers, custom crushing contractors, and material recycling operations the type of performance and convenience needed to recycle or move material in various on-site locations.

Whether it be in high altitudes, cold temperatures, in humid or dusty environments, the KEB F6 Drive delivers on power, high efficiency, and integrated safety for machinery applications that are used in harsh conditions around the world.

Jeffrey Ton adds, “KEB had the perfect solution. For us, the important thing is that we can have it sensorless, as well as have some safety features that are beneficial for our machine. Also, it’s [the F6] a bit smaller, which for us is the next step forward.”

Cost Savings To Customers

The RM 120GO! features Rubble Master’s fuel-efficient diesel-over-electric drive system that burns up to 1/3 less fuel than same-size diesel-hydraulic crushers, leading to a more profitable cost per ton.

KEB’s F6 Drive delivers smooth starting, stable speed control and minimizes mechanical stress on the crusher and its motor. As a result, customers can experience a reduction in maintenance, longer run times, and longer equipment life.

“An electric drive is significantly more efficient and less susceptible than hydraulic offerings from competitors,” said Markus Gaggl. “By working with KEB, our customers can benefit from lower service costs.”

Long-term Partnership

Backed by its innovative RM GO! principle, Rubble Master has grown into a 350-person manufacturer with five sales subsidiaries and is represented by a worldwide network of 107 partners in 110 countries. With its focus on innovation and growth, the company will continue to develop user-friendly, environment-friendly, economical, and mobile products to serve the industry.

The RM 120GO! project was complex and featured unique challenges for both teams. “Building a prototype is always a bit of a learning process,” said Jeffrey Ton. “Of course, we had some problems initially, but KEB was immediately there to help out. Together, we built a separate prototype to do some simulation and which solved our problems. Now we have the servo drive and the other components such as the electric motor in our machine.”

To support Rubble Master’s long-term vision, KEB is more than a solutions provider. Jeffrey Ton explains, “They [KEB] proactively ask how our machine is working afterward. It’s not only doing the project but also later that you really do have the feeling that KEB wants to be a partner and not just a supplier, which is good for our business.”

Contact KEB

Need assistance with a project or technical support? Fill out the form below to connect with a servo drive expert. We are here to help you find or customize a solution to meet your needs.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.