S6 Linear Shaft Motor Drive Solution – Nippon Pulse and KEB America

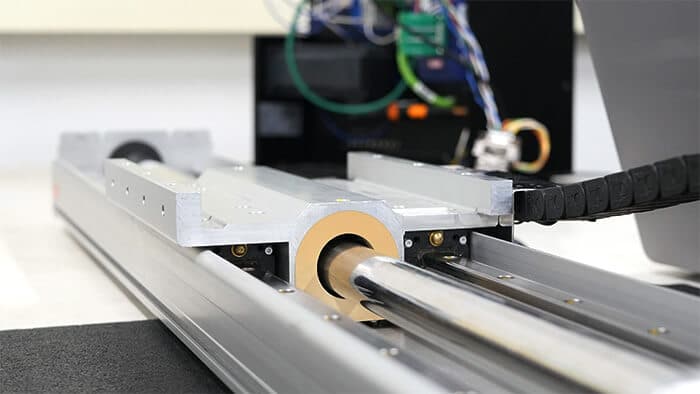

In the video showcased above, KEB America and Nippon Pulse collaborated to develop a solution for linear motors in North America. The video illustrates how the KEB S6 VFD can enable precise and efficient positioning of a linear motor. In this article, we delve into the details of linear shaft motors and the KEB S6 drive.

Linear Motor Drive Overview

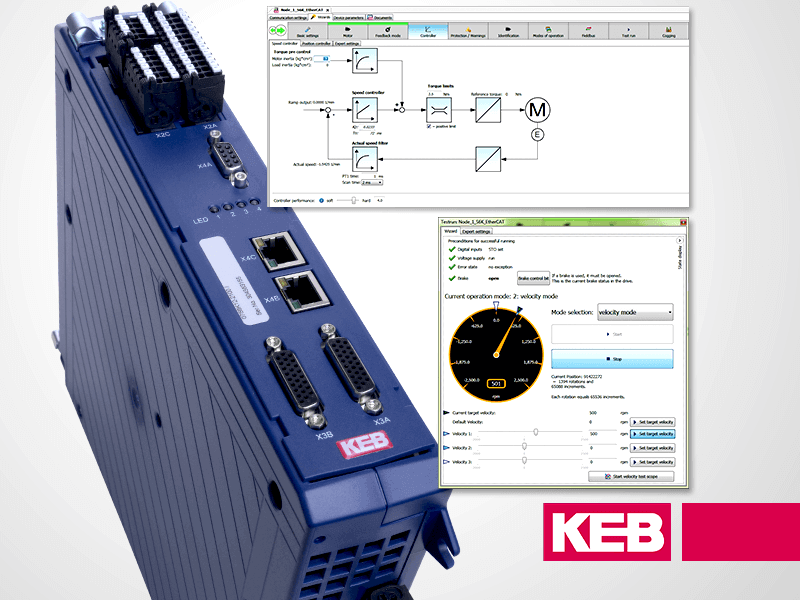

The versatility of KEB’s S6 drive is apparent when paired with Combivis 6 programming software. Smooth control of the Nippon Pulse SLP25 Linear Shaft Motor is achieved, with the drive’s flexibility and in this particular demo, using a HEIDENHAIN LIDA279 incremental linear encoder for precise feedback. Some of the advantages of linear shaft motors include the lack of “cogging” that occurs with a typical brushless DC motor and the reduced noise that comes from magnetic cogging.

For instance, if you rotate a brushless motor in a drill, you can notice resistance and slipping as the magnetic fields interact with each other. A linear shaft motor like the design in the video demo setup does not have any slip or resistance since the magnets are not fighting polarity as the box coil runs the length of the linear motor shaft.

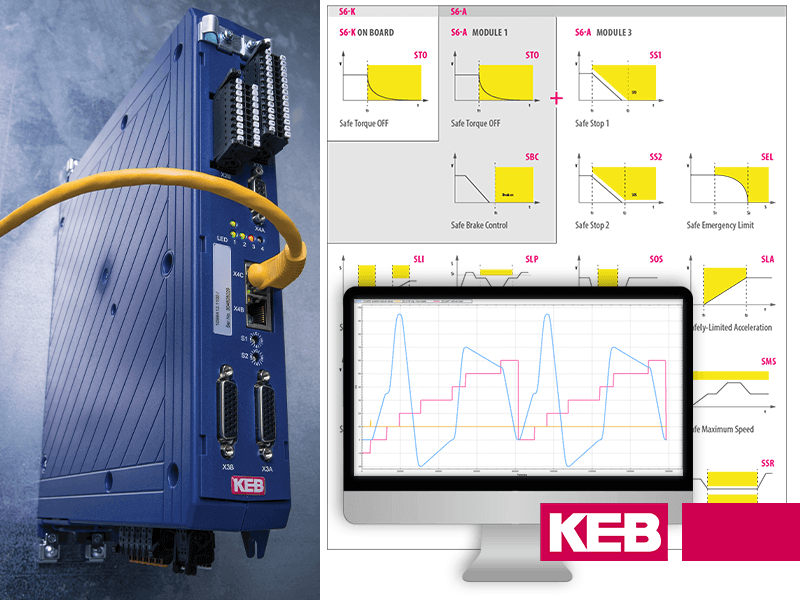

The S6 drive from KEB America offers multiple control options and safety features like STO (Safe Torque Off) to machine builders. This drive product works best in lower horsepower operations up to 10 HP with 1-Phase and 3-Phase options. However, if higher power is required, KEB’s F5 and F6 line of drives are available in graduated sizes up to 1000 HP.

Read More: S6 VFD for Linear Motor Applications

Software Solution for Linear Motors

Looking past the hardware, Combivis 6 accomplishes linear motor control by treating the motor as a “virtual” rotary motor. Imagine a linear motor setup, and then take a section of the linear motor that control is needed within and “cut” it out. Bend this section into a circle with the ends touching to form a circle, and this is essentially how Combivis 6 creates a “virtual” rotary drive. Using the parameters typically used for rotary motors, a linear motor can be directly controlled through Combivis 6, which allows for an easy setup for those already familiar with the KEB software.

Linear Motor Benefits vs. Rotary Motors

There are many advantages linear shaft motors have over traditional rotary motors.

- Direct Linear Motion: Linear motors provide direct linear motion without the need for converting rotary motion to linear motion through mechanical components like gears or belts. This eliminates the potential for mechanical losses, backlash, and wear associated with traditional rotary-to-linear transmission systems.

- High Acceleration and Speed: Linear motors can achieve high acceleration and speeds, often surpassing rotary motors. They provide rapid and precise linear motion, making them suitable for applications that require quick and accurate positioning or high-speed movements.

- Improved Dynamic Performance: Due to their direct drive nature, linear motors offer enhanced dynamic performance compared to rotary motors. They exhibit excellent response time, quick start-stop capabilities, and high servo stiffness, making them ideal for applications that demand rapid changes in direction or precise control.

- High Precision and Accuracy: Linear motors provide exceptional precision and accuracy in positioning. They offer a sub-micron resolution, allowing for precise control over linear motion. This makes them suitable for CNC machines, semiconductor manufacturing, and precision inspection systems.

- Flexibility in Design and Layout: Linear motors offer greater design flexibility than rotary motors. They can be easily integrated into various machine architectures and configurations. Their compact size and flat form factor enable them to fit in tight spaces or be incorporated into complex multi-axis systems more efficiently.

- Reduced Maintenance: Linear motors have fewer mechanical components than rotary motors, reducing maintenance requirements. With no gears, belts, or other transmission elements, fewer parts are subject to wear and tear, minimizing the need for regular maintenance or lubrication.

- Energy Efficiency: Linear motors can be more energy-efficient than rotary motors. Their direct drive operation eliminates energy losses associated with mechanical power transmission, improving overall efficiency.

- Silent Operation: Linear motors operate with minimal noise and vibration since they lack mechanical components that generate friction or impact noise. This makes them particularly suitable for applications where low noise levels are essential, such as medical devices or laboratory equipment.

It’s worth noting that the suitability of linear motors depends on the specific application requirements. While linear shaft motors offer numerous advantages, they may not always be the optimal choice depending on factors such as load characteristics, cost considerations, or environmental constraints.

VFDs for Linear Motor Experts

KEB is thankful for the opportunity to work with Nippon Pulse America to prove the capability of the S6 drive platform with linear shaft motors. With so many benefits, it’s easy to see why linear motors are desirable for many applications. If you want to explore possible solutions for running a linear motor with a VFD like a KEB S6 or F6 drive, contact an application engineer at KEB America.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.