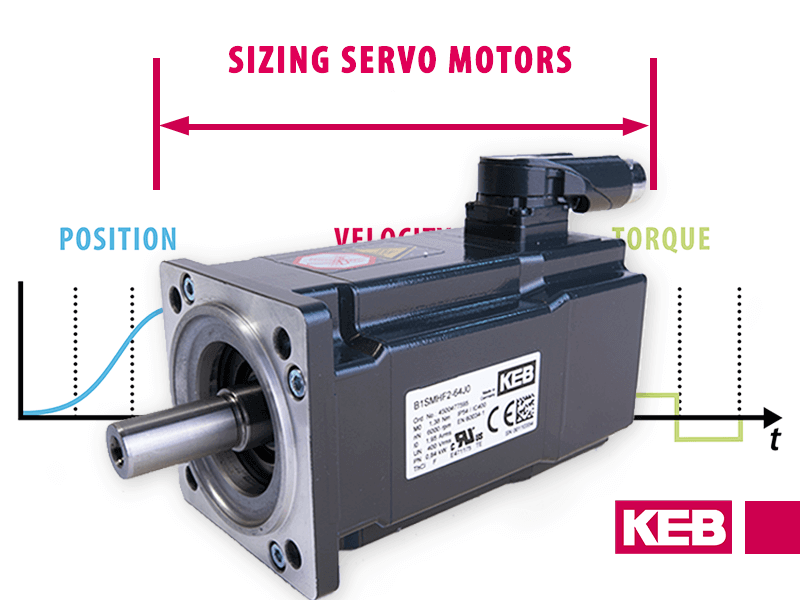

The Combivert S6 drive is a modern, compact and flexible servo amplifier that can be used across a wide range of applications. The drive controller provides optimum performance in torque, speed, and position control. The S6 has the ability to control AC induction motors, AC PM motors, and lastly linear motors. In this article, we will be focusing on linear motors and how they work, as well as the simplicity of controlling them with the Combivert S6.

Related Article: Linear Shaft Motor Solution – KEB America and Nippon Pulse

Linear Motor Overview

Industrial machines often require linear movement to convey, press, and place. Traditionally, rotary motors have been used with additional belts or ball screws in order to translate the rotary movement into the required linear movement. These mechanisms can have limitations including speed, resolution, backlash, and critical resonances. As an alternative, linear motors can be used in machine designs.

Watch the Video: How does a Linear Shaft Motor Work?

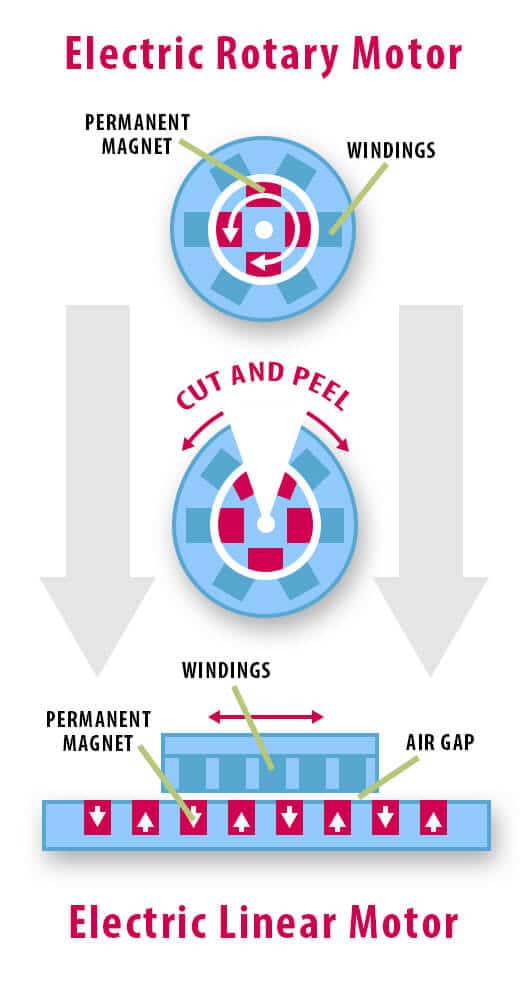

In essence, a linear motor is just a rotary servo motor sliced open and laid out flat. The rotor with permanent magnets becomes the stationary part of the linear motor, while the stator, which consists of the coil windings, becomes the moving part.

Related Article: How a 3 Phase Induction Motor works

By utilizing the principles of electromagnetics, the stator uses 3 phases over the standard 2-phase rotor. The attraction and repulsion between the excited coils and the permanent magnets track create the forward motion. While normal motors produce a torque (rotation), a linear motor instead produces a linear force along its length.

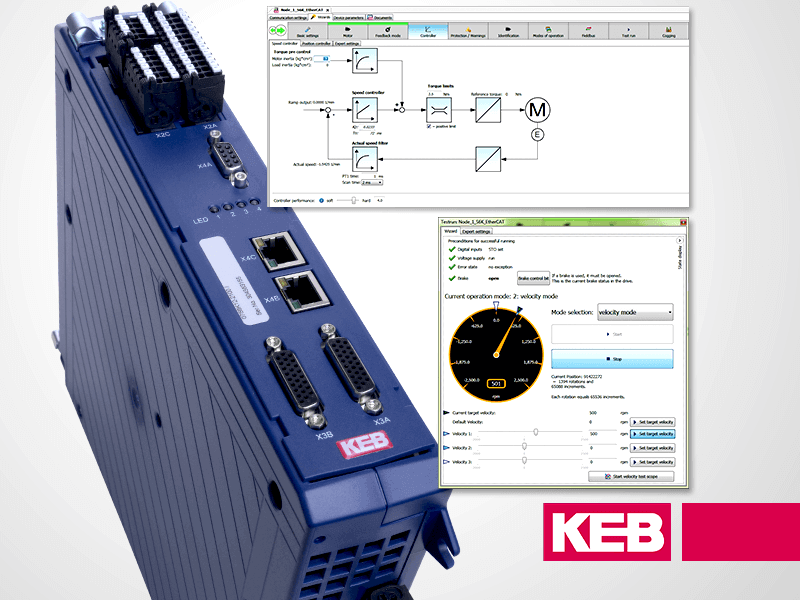

KEB’s S6 Drive for Linear Motor Applications

KEB has experience utilizing the S6 servo drive in linear motor applications with 3D Printing, woodworking and metalworking machines. Typically, these applications involve the control of linear axes in transport arms, movement of tools (sawblades), small pressure beams, or NC-Axes (X, Y and Z). These applications have included linear motors from companies such as Parker Hannifin and LinMot.

Controlling a linear motor with the S6 is very user friendly and the start-up works exactly the same way as with standard rotary servos. Since linear motors do not have a nominal speed, it can be a bit more involved to calculate the rotative data and input it into the drive. However, KEB has the ability to calculate this data using a series of complex equations, making start-up just as simple. KEB application engineers can review motor data and advise on the correct drive settings.

Related Article: S6 Motor Startup Proceedure

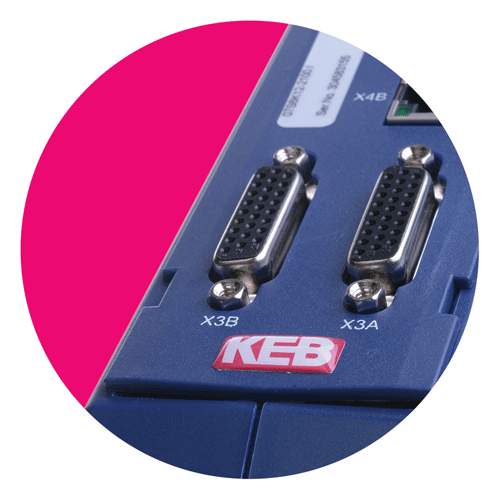

Linear motors utilize encoders to be able to position them correctly and keep them on the track. The Combivert S6 has the ability to use many different encoders, including EnDAT and SSI (with and without SinCos) with linear motors. The S6 also has the capability to perform encoderless positioning of linear motors, which can be effective in certain applications.

Conclusion

KEB provides a simple and effective solution to controlling linear motors in many types of applications. KEB representatives will be able to assist in sizing you a VFD for your application, as well as answer any additional questions you may have.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.