Spring Set Brakes – How They Work

Spring-set brakes are electrically released and provide power-off failsafe braking. This video shows how they work.

Spring Set Brakes: How They Work

[VIDEO TRANSCRIPT]

When electrical power is applied to an electromagnet coil the brake releases and a connected shaft is free to rotate. When power is removed, the brake engages and a connected shaft stops rotating.

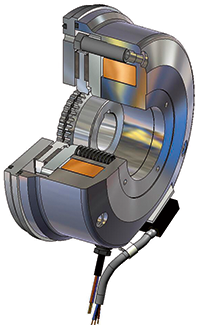

When an electromagnetic coil is powered with DC voltage a magnetic field is created. The magnetic force pulls an armature across a small airgap and compresses multiple springs embedded in the magnet housing. With the armature pulled in flat against the magnet face, the friction lining – which is connected to a shaft hub – is free to rotate.

When power is removed from the magnet, the springs push against the armature. The friction linking is then sandwiched between the armature and a secondary friction surface and a brake torque is created. Since the hub is connected to the friction lining through a splined connection, the shaft also stops rotating until power is applied to the coil again.

Spring applied or spring set brakes have loads of applications – elevators and escalators, wind turbines, cranes, servo motors, and more. KEB offers the Spring-set Type 17 Double C-Face Brake with a variety of options and features. Our sales team can give you the full details and how each feature can be optimized to fit your needs. Use the contact link at the top of this page if you want to chat with us about our Combistop brakes!

For more information, check out our Spring-set Brake product page.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.