KEB’s generation 6 drives can store a list of parameter settings in its internal memory. This functionality is called a recipe. Recipes reduce a machine builder’s dependency on a PLC by storing multiple modes or parameter settings within the VFD. It could be one or two parameters or an elaborate list of every parameter in the drive.

A recipe could be as simple as speeding up the drive’s response time (jerkiness) or changing the default value for all commands. Recipes can also contain multiple settings changes at once. For instance, you can create a recipe with both an X-Y axis speed change and a change to motor current limits. Once created and stored in the drive’s memory, recipes can be activated anytime, allowing users to change the drive’s programming on the fly.

Now that you know what a recipe is, let’s start making some.

Creating a Recipe

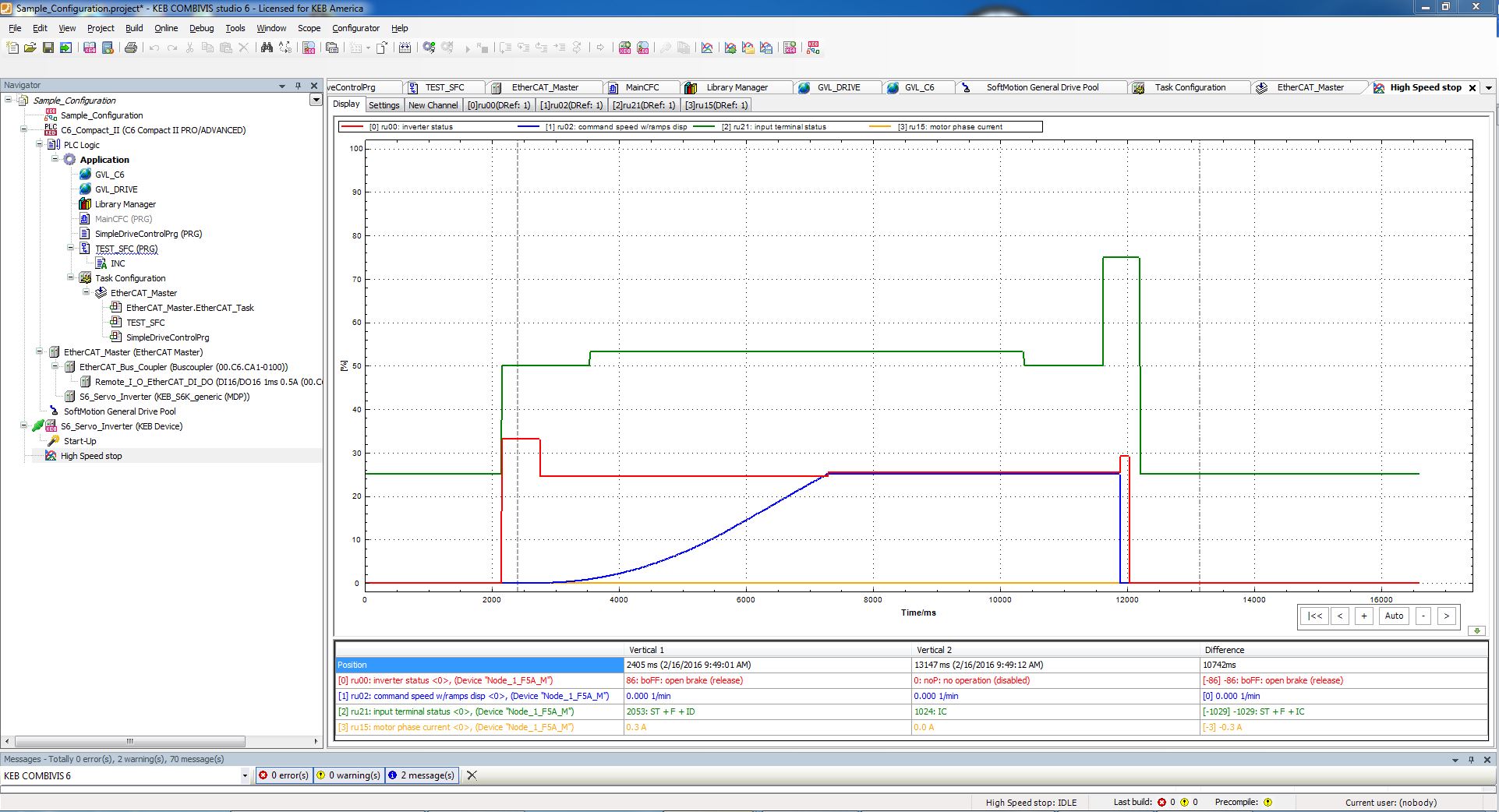

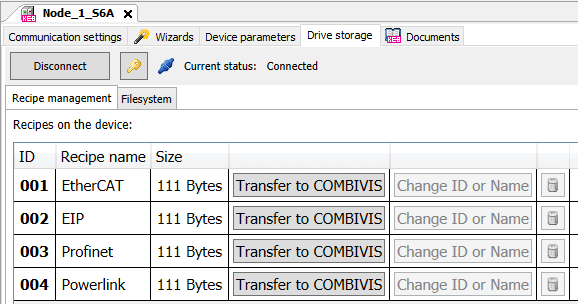

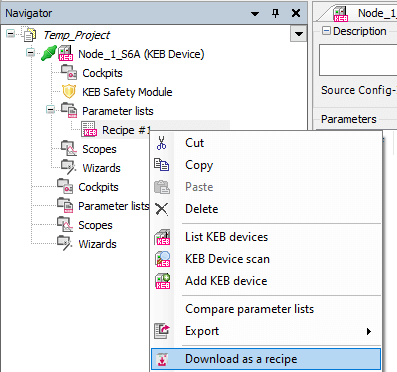

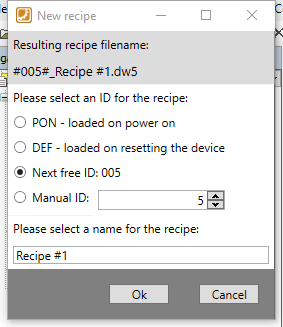

To start using the recipe functionality, create a list of parameter values in KEB’s COMBIVIS 6 software. When the parameter list is stored in the drive’s internal memory through Combivis 6, it becomes a recipe. Each recipe is assigned an ID#. These can be triggered by an input to the drive (digital input or control word) or be done automatically after each power on and/or device reset.

Once triggered, the parameter values stored in that recipe are downloaded into the drive. This overwrites the previous values so that the parameter settings are the desired settings from the recipe.

Using Recipes to Control Multiple Motors

For example, a user wants to control multiple motors using recipes in the drive. First, store the different motor data as separate recipes. When switching to run the other motor, ensure the power output to the motor is swapped. Then select the appropriate recipe. The control logic can stay the same while still ensuring the speed and torque control of the different motors is correct.

Related Video: Start a Motor With an S6 Drive

Finally, the machine designer can guarantee the drive is always programmed properly by allowing the automatic download after a power cycle or device reset. Save a complete program known to run the motor correctly and store it as an automatic recipe.

Note: If a parameter accidentally gets changed or the control seems off, a power cycle or device reset will set the programming back to the last known state to be good. This could save hours during commissioning or troubleshooting in the field.

Recipe Benefits

A recipe may seem like a basic tool, but it offers machine builders flexibility, efficiency, cost savings, and dependency. Allowing the drive to handle basic logic and to change parameter values on the fly can reduce or eliminate the need for a PLC. And it allows for increased customization within the programming and use of the VFD.

Contact KEB

The recipe functionality is one of many powerful features in KEB VFDs. Contact a KEB Application Engineer to learn how recipes can be used in your machine!

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.