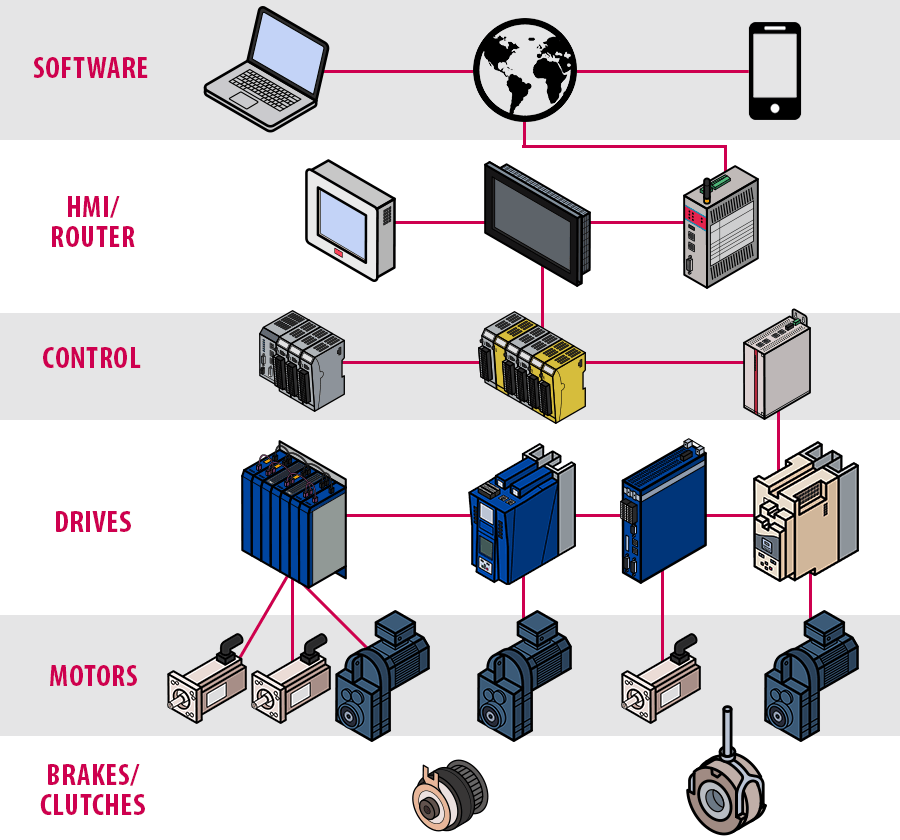

KEB has been a leader in motion control design and engineering for over fifty years. Automated systems need more than a motor, power supply, and brake. Motion control components – like drives, embedded control devices, and logic controllers – are an integral part of automated manufacturing and material handling.

This article is about the basics of motion control and the indexing component of motion control. Every task assigned to a machine will have an index – or move – that it needs to complete the job. What are some typical indexing types and applications, and how are they designed and deployed? Let’s take a look.

Starting with the basic terms we use when talking about motion control indexing, an index will be an angle (rotary) move or a distance (linear) move. The move has a start and a stop, at which point the machine will perform the next task, like filling a pouch or opening an elevator door. Once the task is complete the index sequence starts over. Most indexing applications will use a trapezoidal or S-curve motion profile to make point-to-point movements on a single axis. Coordinated multi-axis movements are also frequently used.

Related Article: EtherCAT Motion Control for Packaging Machines

Motion profiles

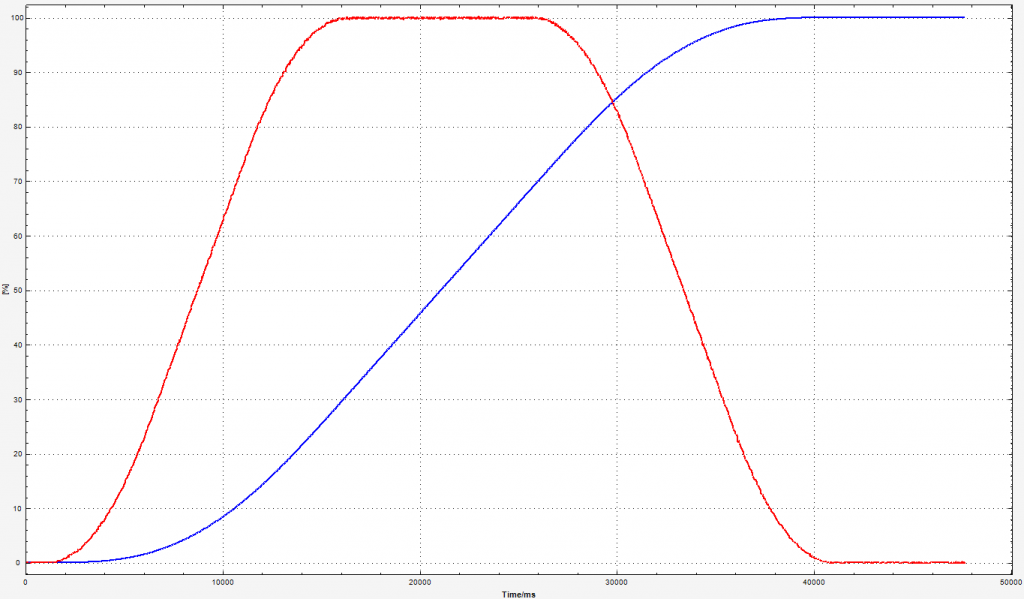

“Motion profile” is the term used to describe the graphical depiction of velocity over time for an index move. Some applications will prioritize speed, while others need smooth movements, so it is important to evaluate the types of available profiles and adjust your machine’s movements to suit the needs of the application.

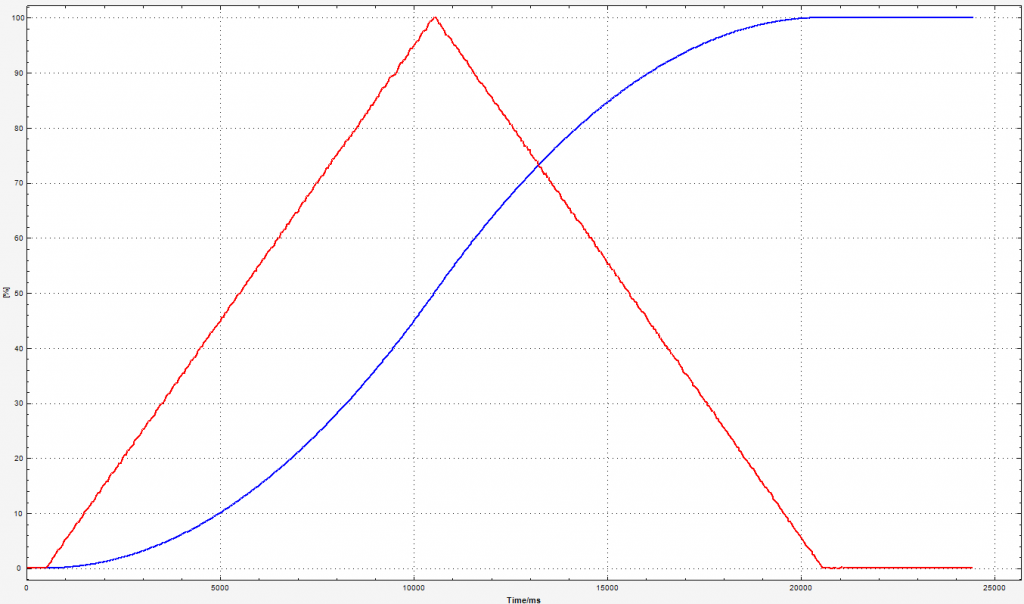

The most basic velocity profile is a triangular profile. The machine movements accelerate to a maximum velocity, then immediately decelerate in the same time and distance as the acceleration phase. It is the fastest way to move from one point to another in a motion profile, however, the change in velocity results in an abrupt jerk. I’ll cover jerk a bit more later.

A trapezoidal profile allows for a period of constant velocity. Mathematically, it is a fairly basic profile but still contains a few inflection points. The three phases of the profile are constant acceleration, constant velocity, and constant deceleration.

However, since the transitions between phases in a trapezoidal profile are instantaneous the machine will experience what is referred to as “jerk.” Jerk is pretty much what it sounds like. The abrupt movements caused by rapid or instantaneous changes in velocity make the movement jerky or unstable. This is not desirable for machines moving packages that could easily overflow and spill, or an escalator carrying passengers, for example.

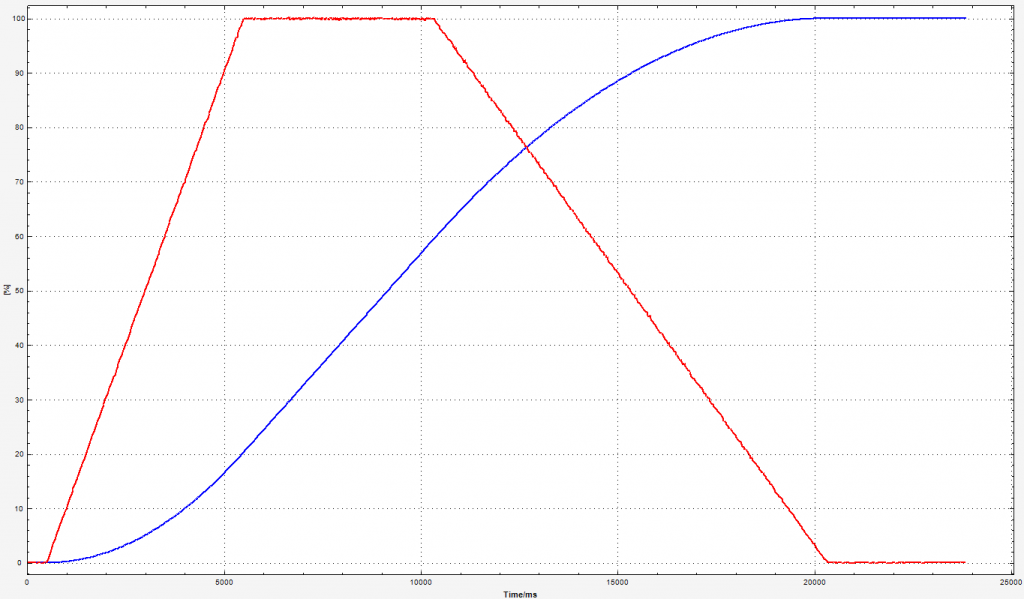

Though it involves sacrificing some of the speed of a trapezoidal profile, adding the jerk phases of an s-profile will smooth out the abrupt transitions.

The additional phases can also minimize backlash and machine wear and tear. Integrators who wish to use an s-curve profile will need to do some close observation during the initial run to ensure the jerk value is properly calibrated. A well-calibrated s-curve profile will provide a good balance of velocity, acceleration, and acceptable jerk.

Index movements

Drives and controllers from KEB are an important part of translating the desired movements from the human designers to the machines that perform the tasks. Depending on the type of movement your machine must make you will need to choose the correct method of control.

When we talk about motion control and factory automation things like hoists and conveyors might pop into your mind. These are good examples of applications that would use linear point-to-point movements along a single axis. For applications like these, the F5 VFD or the new F6 VFD are excellent tools to use. Every drive in the F5 series contains a 32-bit position module with the possibility to load in a table of preset positions.

For applications that need to move across multiple axes – robotic arms for ASRS applications or people flying for theatre, for example – a different kind of drive is needed because multiple indexes need to be coordinated. It’s still a point-to-point movement, but now we’re moving in 2D or 3D space. The H6 Multiaxis Drive uses a shared DC bus connection allowing multiple single- or double-axis drive modules. The drive can be connected to multiple PLCs or controller units as well, so even very complex coordination can be set up.

In situations where coordination over multiple axes is required or index lengths need to be adjusted on-the-fly KEB’s C6 SMART embedded controller is a great addition. The external motion controller can give dedicated control to each index, providing tighter synchronization and advanced profiles.

Another type of movement that can be done with motion control indexes is simulated or electronic gearing. Using KEB’s COMBIVIS Control Runtime software with a pre-developed library of Axis Utility operations you can implement complex synchronized movements without using physical gearing.

Another type of movement frequently used involves the interpolation of a string of points to create a smooth path called contoured motion. If adding an s-curve does not sufficiently buffer the starts and stops of the motion, using contoured motion can help.

Application spotlight

Here are a few motion control applications and how indexing affects each one.

Rotary table

A rotary table can be used in metalworking, packaging, filler, and other material handling applications. In metalworking, for example, the piece to be machined will be rotated in position by the table in one move, then a drill or saw moved into place with a second. The motion profile translates into an angular, point-to-point position around the wheel. Once that motion is completed the next sequence is started.

Conveyor

A rotary table might have two indexes that run concurrently, while a conveyor might need several indexes that run simultaneously, though this is not true for every case. The motion profiles for the flying saw application must be synchronized so cuts are made evenly and cleanly. However, if a line must stop so another task like filling or sealing can be done the profiles will need to run asynchronously with precise timing. Some conveyors can run with jerks in the profile, but others, like an escalator or other people-moving system, must be smooth for the safety of its passengers.

Sheet feed

Feeding individual sheets of metal or paper or planks of wood into a machine from a stack requires a few movements. Like rotary tables and conveyors, there will be an index to spin rollers, moving the product onto the line. But before the product gets to that point, it starts in a stack which is incrementally moved up and into position, then a single item can be picked, pushed, or pulled into place.

This blog post on indexing should give you an introduction to one of the basic parts of motion control. Future posts in this series will highlight other important components and how they all combine together to make a modern, efficient machine installation.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.