The role of the IT professional in Industry 4.0

In most installations, setting up network connectivity falls to a department that previously wouldn’t have been involved in purchasing decisions for the factory floor – the IT department. Recent surveys among integrators that have begin setting up IIoT-ready automation processes have indicated that nearly a quarter of all purchase decisions for these installations will involve IT, and in many cases these purchases will be a line item in the IT budget. Though a product may be used by the engineers, KEB recognizes every department within a company will have different business goals, different bottom lines. In IIoT, there’s an intersection of interests between engineers and IT so the products offered need to serve both of these.

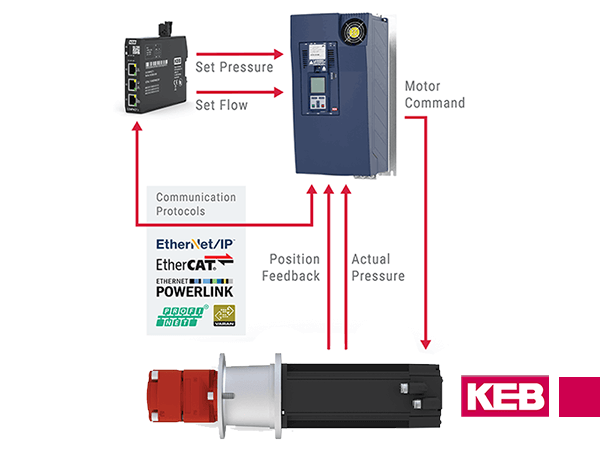

In a previous post, I went over how data-gathering techniques that are a part of IIoT devices can be used to improve the productivity of an installation. KEB drives, like the F5 Inverter, have the ability to send data to devices with logging capabilities. Being a part of industry 4.0 is building a system in which this communication takes place as part of the IT department’s new role in factory automation. KEB’s products are able to speak to each other using one of more than a dozen communication protocols. Additionally, our C6 VPN Router can be integrated wirelessly, or using a wired network. By using KEB products an integrator will give their IT department maximum flexibility for designing the communication network.

It’s more common, however, for our customers to be updating their existing installations rather than starting from the ground up. Many of KEB’s products are designed for a long product and support lifetime. The F4 series of drives, for example, was produced for over twenty years before we updated to the F5 which has now been going strong for fifteen years. We hope that all of our products will see many years of use in a customer’s installation, so we endeavor to make our new products easy to integrate into existing systems. Even third party products can work well with KEB’s IIoT-ready devices. Are you using an Allen Bradley PLC? We can work with that. This feature – the ease of integration – is what we feel makes our IIoT products truly IT-friendly.

When it comes to industry 4.0 and the IT department’s role in a company, we know they have loads of responsibilities on their plate. Adding into this the necessity of installing and maintaining the factory floor’s communication network shouldn’t be a roadblock to the newest technology and the future of machine automation. Give us a call, or send us an email, and we’ll help you make your IT professional’s job easier.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.