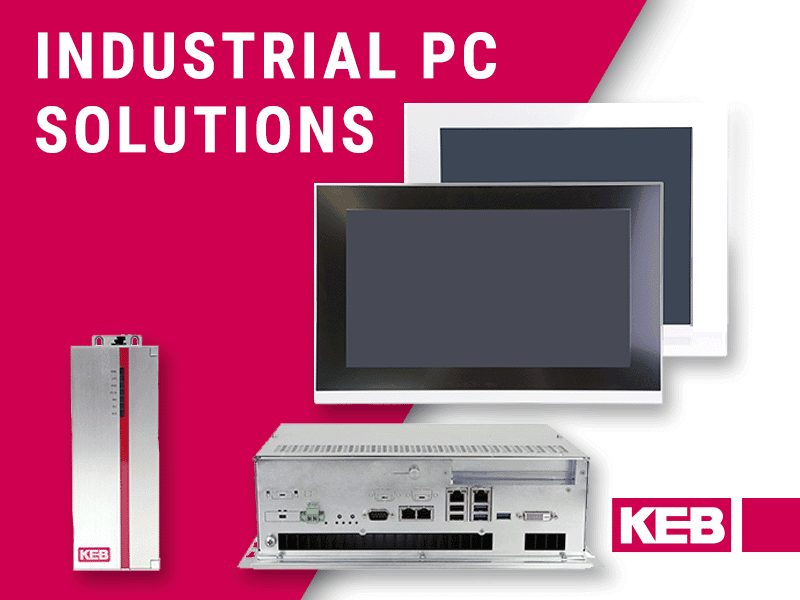

Top Industrial Panel PCs for Commercial Applications

Panel PCs are versatile computers built for commercial applications. In recent years, they’ve become a go-to for industrial computing tasks, controlling production lines and gathering system performance data in real-time.

Panel PCs are an all-in-one solution: a fanless, dustless computer with a responsive touchscreen for HMI (human-machine interface).

Why are industrial panel PCs so popular in commercial applications?

In short: simplicity and flexibility. Panel PCs play well with almost any existing IT architecture, making integration quick and seamless. This hardware is rugged, too, handling the wear and tear of tough industrial work environments with durable parts and in-built protections.

Despite their strengths, not all industrial panel PCs are created equal. If you’re seeking a PC for your application, you’ll have to find one with features and proven results to match your needs.

To get you started, here are three of the best industrial, commercial panel PCs for commercial applications—and the unique strengths they bring to this ever-changing market.

1. C6 S14 IPC

The C6 S14 is an industrial touch screen IPC with PLC + HMI capabilities. Built to be a true all-rounder, it offers a complete range of functions: control, visualization, and remote maintenance. The S14 works best for medium-high performance machines thanks to its powerful ARM Cortex A9 processor.

It’s also available in multiple sizes and display formats, making it one of the most versatile and easy-to-install PCs on this list.

A key challenge with industrial panel PCs is dependability. Commercial environments expose computers to excessive temps, dust, moisture, and many other harmful elements—any of which can damage a touchscreen panel.

Furthermore, operators often use gloves while interfacing with workplace machines to keep their hands safe and clean, making conventional touchscreen use difficult.

Top Features

This is where the S14 shines: it delivers resistive touch technology. The S14’s resistive touchscreens are highly durable, with strong resistance to dust and water. They’re also responsive enough to be used with gloves or styluses.

Like other industrial PCs, the S14 is easy to wash down and clean, making it well-suited for Food and Beverage applications.

Other common use cases for the C6 S14 IPC include Metalworking Machinery and Material Handling. This IPC thrives even in remote installations because of its remote maintenance capabilities.

KEB’s CONNECT infrastructure enables remote maintenance of machines anywhere through secure end-to-end connections, ensuring devices keep operating smoothly at all times.

Use Case

PLC + HMI for medium-high performance machines, real-time motion control.

2. C6 E22 IPC

The C6 E22 is a multi-core industrial PC with an EtherCat master designed for real-time coordinated motion control. Efficiency is the main draw of this PC, particularly in applications requiring CNC (computer numerical control) functionality.

Complete with a durable glass front panel, full HD resolution, and a 64-bit Intel® Bay Trail chipset, the E22 is a robust workhorse for commercial use.

Top Features

C6 E22 IPCs are ideal for CNC automation, supporting 10+ axes of coordinated motion control. They include helpful features to manage risk and help CNC operators quickly and safely complete tasks.

For example, the E22’s resistive touchscreens provide full HD resolution and picture clarity. This visualization is crucial for CNC, with operators wearing protective gear that restricts vision, like safety glasses.

E22 IPCs boast a ventless design to reduce the risk of any internal parts failing—even when exposed to constant operation and contaminants. This allows them to perform for extended periods without the heavy maintenance. These fanless panel PCs come in various sizes and formats to suit specialized work environments.

Users focused on space efficiency will appreciate the E22’s slim (SL) version, which is tailor-made for small workspaces. The panel SL is only 48mm – 65mm in-depth, with long-life components and impressive operating capabilities.

Use Cases

Industrial PC for high-performance industrial machines, including CNC applications.

3. C6 P34 IPC

The P34 is the most powerful industrial PC KEB America offers, combining 6th-gen Core i5 processors inside an industrial-grade touchscreen panel. It brings remarkable processing power and performance alongside a capacitive touchscreen for precise movements like scrolling or pinching.

Top Features

The P34 IPC is designed with high-performance industrial machines in mind. Its rugged design offers protection from total dust ingress and high-pressure water jets from any direction. P34 IPCs excel even on busy factory floors, giving operators easy access to machine data in HD resolution.

As a larger cousin of the E22, the P34 IPC is a popular control device for CNC. With 4-core processing power and resilient parts, this touchscreen display IPC thrives in the harshest industrial applications.

It offers capacitive and resistive touch, crystal-clear resolution, and a USB interface on the front, delivering unmatched efficiency across CNC workflows and beyond.

Use Cases

Panel IPC for high-performance industrial machines requiring coordinated motion control, including CNC functionality.

Industrial Panel PCs for Commercial Application

Touchscreen industrial panel PCs are potent solutions for almost any industrial field. These PCs can help your business redefine efficiency, reduce waste, and minimize machine downtime across locations and operations.

We’ve explored KEB’s best industrial panel PCs in general, but finding the right option for your unique business is a more difficult matter.

Which Industrial Panel PC Is Right for Your Business?

Remember, your panel PC will have specific requirements depending on your industry, workspace, and production process. Failing to consider these will cause you to over-invest in excessive features—or under-invest in a tool that’s not powerful or robust enough to meet your needs.

This is why it’s important to consult with an experienced solutions engineer before investing in an industrial panel PC.

You’ll want to test how a specific PC performs in a comparable environment to yours for the best results. Solutions that look great on paper can fall when put into practice. Even a small miscalculation in sizing or formatting can cause bigger problems, especially if you need to integrate with an existing production line.

Proper testing and preparation will help you avoid these challenges and ensure the panel PC you choose starts delivering value from day one.

Connect with a KEB solutions engineer today for more information on industrial panel PCs and select the right model for your commercial application. We look forward to serving your business and achieving your goals together.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.