Top posts of 2016 – thank you readers!

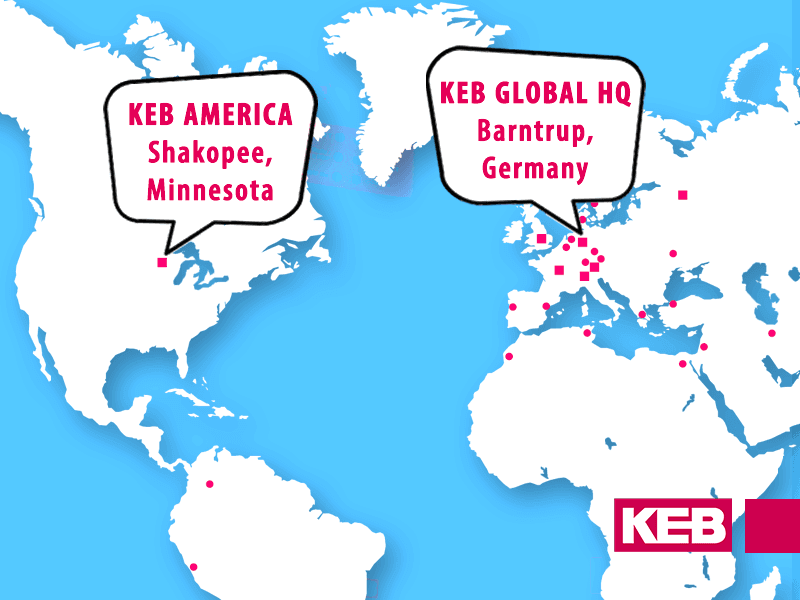

For over 40 years KEB has been a leader in control and automation products. In mid-2015 we started the KEB blog as a way to share our expertise with the engineering community. Our goal is to reach out to anyone who might have an interest in what we do here at our facility in Minnesota, or at any of the other KEB locations around the world. We want to tell you more about our products, how to use them, and how you can get the most out of your machines.

To mark the beginning of a new year of blogging, I’ve compiled a short list of our most popular posts from last year. Thank you to all of our readers, and stay tuned – we have some great topics in store for 2017!

5. VFD Regenerative applications

This post discusses VFD regenerative applications – applications that regenerate energy and the common drive options and topologies that are available.

A motor is simply an energy conversion device. Most commonly, we think of inputting electrical energy to a motor and it converts it to a mechanical torque which does some work on a load. This is called “motoring mode”. But depending on the nature of the connected load, a motor can also operate in the reverse. It can convert a torque into electrical energy, this is called “generating mode” or regeneration.

4. Energy Savings with Escalator Drives

This post describes how using a VFD to control an escalator motor can reduce energy consumption compared to conventional line start control. It is the second of three posts on escalator drives – the first post described how using a drive to control an escalator can provide operation and performance advantages.

The benefits from operating an escalator motor with a VFD generally come in two forms: 1) operational or performance advantages and 2) energy savings. KEB has created these posts to help customers, consultants, and users understand the benefits of applying KEB’s energy saving accessories to their escalator VFD.

3. Legacy Elevator VFD upgrade with KEB F5 Inverter

In the elevator industry the implementation of variable frequency drives for the control of AC motors didn’t really begin until the late 1980’s, but over the course of the next 20 or so years AC motors as well as VVVF drives began to rapidly replace their DC counterparts. Generally, these drives have a usable life of about 10 to 15 years before they require replacement. Unfortunately, direct replacement of the original drive is sometimes not possible because companies that previously manufactured the drives have either gone out of business or ceased production of that particular unit. Older elevator drive manufacturers Baldor, SWEO, and Unico come to mind.

This can be a serious problem because changing drives often introduces a hefty cost to engineer the controller to accommodate a different layout of inputs. Luckily, with the new v3.21 US Lift software for the KEB F5 it is possible to completely customize the input layout of the drive to allow it to match the operation of many older generation drives such as the Baldor/SWEO 18H or Yaskawa F7.

2. Optimizing high speed motors with KEB

High speed motors may run with very small rotor clearances on the bearings. Rotor heating becomes a concern as any elongation or expansion of the rotor due to excess heat can cause the rotor to impact the bearing. In applications requiring very low harmonics on the output waveform, KEB produces a line of high speed sine filters to filter the output voltage and current waveform to a near sine wave to keep the rotor heating to a minimum. KEB SCL software is designed to run with an output sine filter. The software also incorporates an electronic filter to avoid resonance issues between the drive/sine filter/motor combinations.

1. C6 VPN Router – Remote Machine Connection

KEB’s C6 industrial VPN Router allows a user to make a secure VPN connection to a machine or PLC. There is a lot of discussion right now around the Industrial Internet of Things (IIoT) or Industry 4.0. In short, IIoT is the ability to connect a machine or machines to the internet. So certainly, the Router deserves a place in the IIoT discussion.

The advantages of remote connecting to a machine are pretty clear and could help the following: start-ups, troubleshooting, diagnostic gathering, preventative maintenance, and so on. But equally important is a discussion on the dangers and pitfalls involving implementation and security. I will save those discussions for another post or for the trade magazines. Instead, this post introduces the C6 Router product and its advantages.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.