Some applications (fans, pumps, etc.) might benefit from running multiple induction motors at the same time from one VFD. This post gives an overview of running multiple motors from a central VFD.

Three Advantages to Using One VFD to Control Multiple Motors

Smaller cabinet size

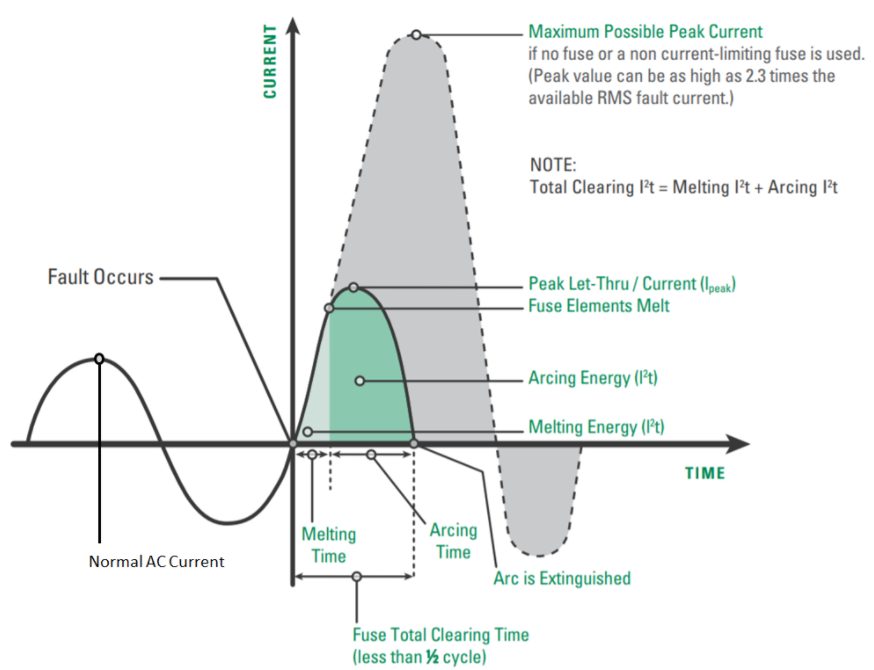

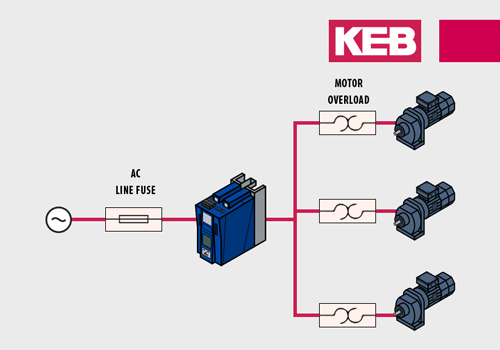

One large drive will have a smaller footprint than multiple smaller VFDs. Additionally, that one large drive requires only one branch circuit protection (e.g. fuses), incoming wiring, and braking resistor. The net result is a smaller electrical enclosure.

Cost reduction

There will be some economic savings in using one large drive compared to many smaller drives. There will be similar savings due to line fuses, brake resistors, and a smaller enclosure. There will be added cost for motor overload protection (described later) but this is more than offset by the other factors.

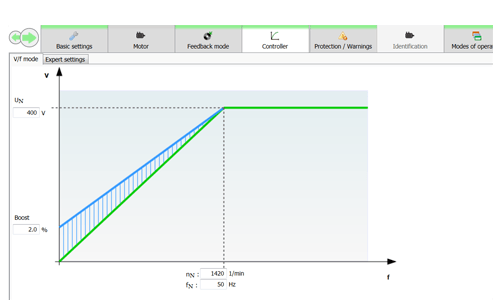

Simple parameter adjustment

One cost often underestimated is the start-up and commissioning time. A centralized drive will have only one set of parameters that need to be configured and set. The parameter adjustment usually entails the setting of the V/Hz curve and required system protection parameters. This can be easily handled in KEB’s free Combivis drive software.

Considerations

Drive size

At a minimum, the drive should be sized to handle the sum of the FLA-rated currents for all connected motors.

A best practice would be to add an additional 20-25% current capacity as a safety factor.

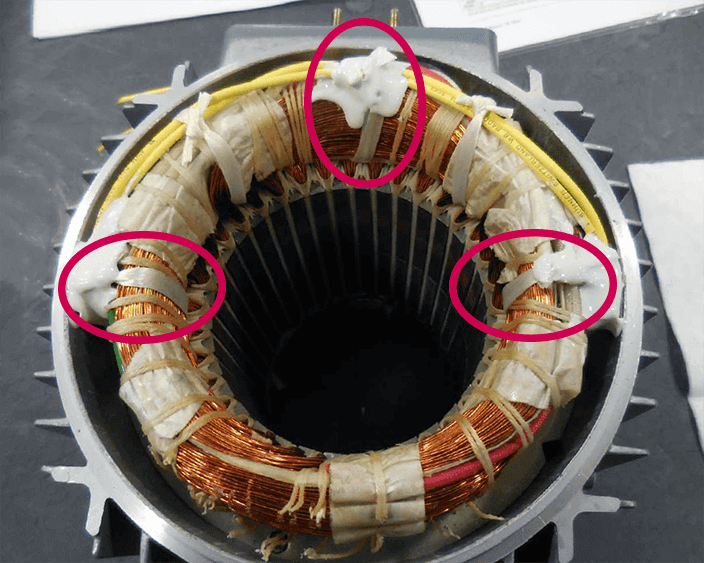

Each motor must have its own individual overload protection

Drives typically include functionality that detects motor overloads and can shut down appropriately. KEB drives comply with the motor overload functionality described in VDE 0660, Part 104. The functionality allows the motor-rated current to be entered into the drive. Then the drive measures the instantaneous and time-averaged output current to detect an overload situation and shutdown.

If multiple motors are connected to the VFD, the VFD cannot tell how much of its output current is being delivered to each motor. Therefore, it cannot determine a motor overload situation. Furthermore, due to sizing, the drive is typically able to provide much more current than one motor can handle.

This means that each motor should have its own motor overload protection.

Motor shaft performance

The motors will load share but they are not synchronized. This is likely fine for the air handling or pump applications but will not work for winding applications or anything that requires a tight speed regulation.

If this topology does not meet the required speed regulation, then a different drive topology (e.g. master-slave configurations) will need to be implemented.

KEB – The VFD Leader

Could your application benefit from running multiple motors from one VFD? If so, contact a KEB engineer to discuss today.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.